Two Waterloo chemists have made it easier for manufacturers to produce a new class of faster and cheaper semiconductors.

Derek Schipper, Canada Research Chair in Organic Material Synthesis, and Serxho Selmani, a doctoral candidate in the Department of Chemistry, have found a way to simultaneously control the orientation and select the size of single-walled carbon nanotubes deposited on a surface. That means the developers of semiconductors can use carbon as opposed to silicon, which will reduce the size and increase the speed of the devices while improving their battery life.

"We're reaching the limits of what's physically possible with silicon-based devices," said Schipper, a professor of Chemistry and a member of the Waterloo Institute for Nanotechnology. "Not only would single-walled carbon nanotube-based electronics be more powerful, they would also consume less power."

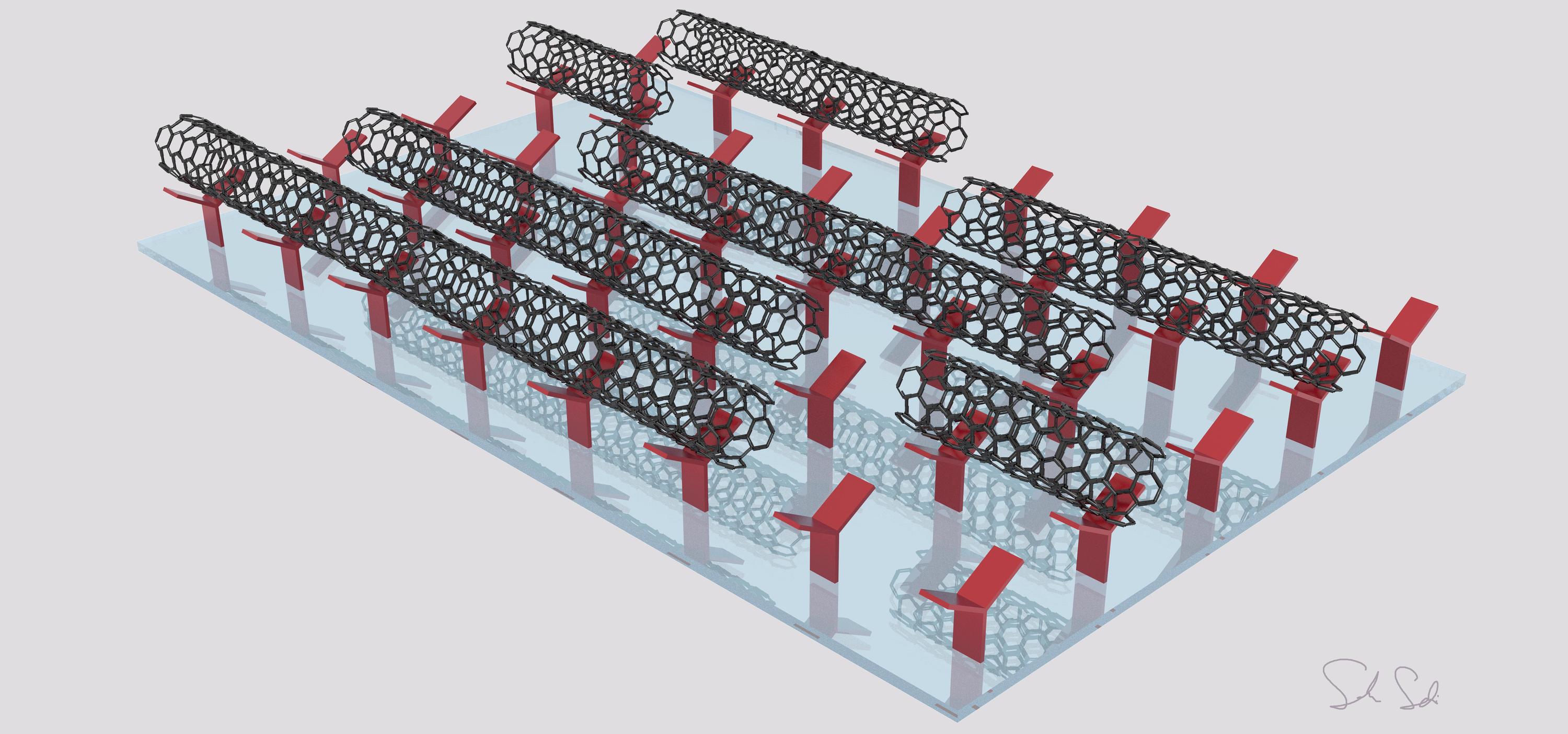

The process, called the Alignment Relay Technique, relies on liquid crystals to pass orientation information to a metal-oxide surface. Small molecules called iptycenes then bond to the surface locking the orientation pattern into place. Their structure includes a small pocket large enough to fit a certain size carbon nanotube that remains after washing.

"This is the first time chemists have been able to externally control the orientation of small molecules covalently bonded to a surface," said Schipper. "We're not the first ones to come up with potential solutions to work with carbon nanotubes. But this is the only one that tackles both orientation and purity challenges at the same time."

Schipper further pointed out that the approach is from the bottom up with the use of organic chemistry to design and build a molecule which then does the hard work.

"Once you've built the pieces, the process is simple. It's a bench-top method requiring no special equipment," Schipper explained.

In contrast to self-assembly techniques which rely on the design of a suitable molecule to fit snuggly together, this process can be controlled at every step, including the size of the iptycene "pocket". In addition, this is the first solution that has been found that tackles the challenge of aligning and purifying carbon nanotubes at the same time

The study appeared this week in the journal Angewandte Chemie International Edition.