North America has 10 million kilometres of overhead power lines, and when vegetation come into contact with one, it can be like tinder to a flame.

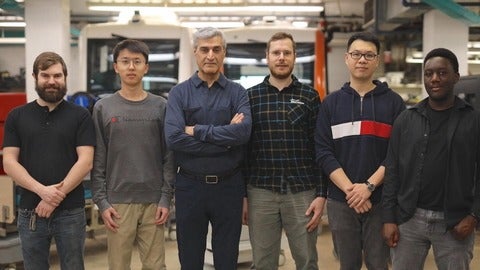

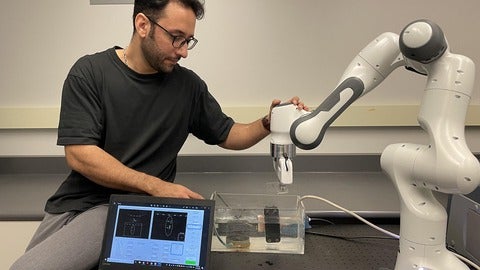

“Once they come in contact with trees, the risk of forest fires increases,” says Anson Maitland (PhD ’19), co-founder of Enerza, a company at Velocity, University of Waterloo’s startup incubator. “With our robot, utilities can spot vegetation risks, corrosion or birds' nests near the line and send out a team to handle it.”

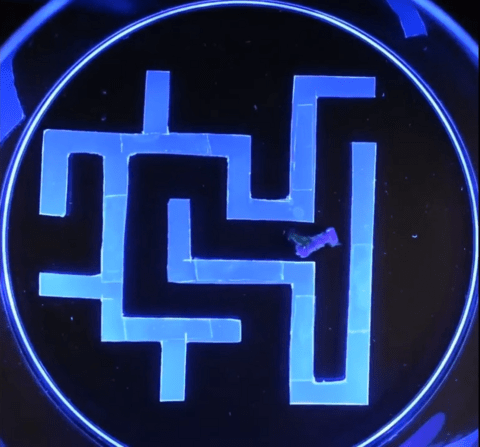

He says that much of North America’s power infrastructure was built in the 1960’s or 70’s. Power lines are often found in rural, forested areas and only monitored on average once every five years. While aware of the problem and eager for a solution, utilities companies don’t know where to best spend their operating dollars.

And without better monitoring tools, it’s difficult to know where and when to do maintenance.

“How would they know which ones to maintain or replace?” says Maitland. “With the robot they can inspect infrastructure more frequently and know with confidence when and where to replace power lines or trim trees.”

Enerza co-founder James Aein says the company’s tech is not just a robot but also a grid analytics platform. Just like a health care provider uses medical imaging to investigate patients’ health before invasive procedures, it gives utilities a whole picture of risks and maintenance needs.