Abstract

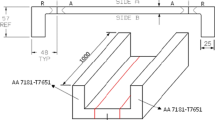

Aluminum vehicular bridge decks figuhave been increasingly used for the replacement of deficient bridge slabs made from reinforced concrete or steel. The design of these decks has been under increasing development since the late 90s and different types of vehicular bridge deck profiles have been industrialized. Aluminum vehicular bridge decks are mainly manufactured through joining several extrusions together by means of welding. Initially, traditional fusion welding techniques were used in the fabrication process. However, more recently, a relatively new technology, friction stir welding (FSW), was used in certain bridge projects. FSW is proving to enhance the welding quality and the overall mechanical performance of the joint compared to traditional welding techniques. However, unlike fusion welding techniques, FSW standards and specifications still lack important quality control criteria and tolerance levels for common FSW defects. In this context, this paper aims at defining tolerance levels for common FSW fit-up defects in aluminium bridge deck application. First, FSW trials of typical vehicular bridge deck extrusions were conducted to determine the welding parameters yielding a sound welding quality. Then, fit-up defects such as gap and tool offset were investigated experimentally, and tolerance levels were determined following a concise stage prequalification process. It was found that a gap of 1.5 mm and a tool offset in the retreating side (RS) of 1.5 mm were acceptable limits. It was also shown metallographically that the level of the tool offset in the advancing side (AS) of 5 mm presented a sound weld quality with a continuous remnant oxide layer within the weld nugget.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Alumabridge LLC (2021). AlumaBridge Latest News - Prefab Bridge | Temporary Bridges | Modular Bridges | Open Grid Design. http://www.alumabridge.com/latest_news.htm

Aluminum Technology Centre (2019) https://nrc.canada.ca/fr/recherche-developpement/installations-cnrc/centre-technologies-laluminium

American Welding Society (2014) AWS D1.2:2014 Structural welding code: Aluminum

Amira S, Giguère N, Toupin M, Toupin J-D (2018) The manufacturing of the new Pedestrian bridge of the Petite Décharge river (Alma, Quebec, Canada). Implementation, lessons learnt and future perspectives. In: 12th International symposium on friction stir welding. Chicoutimi, Canada

Desjardins V (2019) Construction et Observation Du Pont à Platelage En Aluminium de Saint-Ambroise | Centre d’expertise Sur l’aluminium. https://ceal-aluquebec.com/construction-et-observations-du-pont-a-platelage-en-aluminium-de-saint-ambroise/

Fleury A (2020) Conception En Fatigue Des Joints Soudés Par Friction Malaxage Dans Les Tabliers de Point En Aluminium. Université de Québec à Chicoutimi-UQAC, Chicoutimi, Canada

Freeman C (2017) Aluminum lightweight orthotropic deck evaluation project

Guo S, Shah L, Ranjan R, Walbridge S, Gerlich A (2019) Effect of quality control parameter variations on the fatigue performance of aluminum friction stir welded joints. Int J Fatigue 118:150–161

Hydro (2021) Friction stir welding (FSW)—about the process and equipment, some user applications, the benefits and the comparison with fusion welding. Hydro.Oslo, Norway

Inada K, Fujii H, Ji YS, Sun YF, Morisada Y (2010) Effect of gap on FSW joint formation and development of friction powder processing. Sci Technol Weld Joining 15(2):131–136

International Organization for Standardization (2011) ISO 25239 Part 5: Quality and inspection requirements

Jolu TL, Morgeneyer TF, Denquin A, Gourgues-Lorenzon AF (2015) Fatigue lifetime and tearing resistance of AA2198 Al-Cu-Li alloy friction stir welds: effect of defects. Int J Fatigue 70:463–472

Ranjan R, Oliveira Miranda AC, Hui Guo S, Walbridge S, Gerlich A (2019) Fatigue analysis of friction stir welded Butt joints under bending and tension load. Eng Fract Mech 206:34–45

Shah LH, Midawi ARH, Walbridge S, Gerlich A (2020) Influence of tool offsetting and base metal positioning on the material flow of AA5052-AA6061 dissimilar friction stir welding. J Mech Eng Sci 14(1):6393–6402

Thomas B, Svendsen H (2021) How aluminium is competing with steel on long suspension bridge girders. https://www.shapesbyhydro.com/en/material-properties/how-aluminium-is-competing-with-steel-on-long-suspension-bridge-girders/

Walbridge S, de la Chevrotière A (2019) Opportunities for the use of Aluminum in vehicular bridge construction. Aluminum Association of Canada

Xu R, Wei Z, Jiang J, Hou Y, Li H, Cui S (2020) Friction stir Butt-lap welding of A7N01P-T4 aluminum alloy: efforts to mitigate defects and the resultant mechanical properties. Proc Inst Mech Eng Part L J Mater Des Appl 234(6):873–880

Acknowledgements

The authors are grateful for the funding provided by the Fonds de recherche du Québec: Nature et Technologie, FRQNT.

Welding of the extrusions was done by Mr. François Nadeau and Mr. Mario Patry from the National Research Council of Canada (NRC) in Saguenay (Canada). Their support and expertise are highly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 Canadian Society for Civil Engineering

About this paper

Cite this paper

Trimech, M., Annan, CD., Walbridge, S., Amira, S., Nadeau, F. (2023). Defects and Quality Control of Friction Stir Welded Joints in Aluminum Bridge Decks. In: Walbridge, S., et al. Proceedings of the Canadian Society of Civil Engineering Annual Conference 2021 . CSCE 2021. Lecture Notes in Civil Engineering, vol 248. Springer, Singapore. https://doi.org/10.1007/978-981-19-1004-3_43

Download citation

DOI: https://doi.org/10.1007/978-981-19-1004-3_43

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1003-6

Online ISBN: 978-981-19-1004-3

eBook Packages: EngineeringEngineering (R0)