Contact

![]()

Carolyn Ren, Department of Mechanical and Mechatronics Engineering

Carolyn Ren, Department of Mechanical and Mechatronics Engineering

Weijia Cui, Department of Mechanical and Mechatronics Engineering

Weijia Cui, Department of Mechanical and Mechatronics Engineering

Introduction

Heavy metal pollution remains a significant global concern with serious environmental and human health impacts. Often resulting from human activities, such as agricultural, industrial or mining processes, remediation of contaminants such as lead, mercury or chromium, remains challenging as these metals are non-biodegradable and can be present in water, soil, air or food.

Several methods have been developed to detect and quantify heavy metals. Conventional methods generally require expensive, centralized laboratory-based facilities with highly-trained personnel. Rapid, affordable, point-of-care (POC) systems offer an alternative by enabling real-time, in-situ sensing of samples. Microfluidics offers potential for developing POC systems that integrate sample preparation with various heavy metal detection methods. This review paper summarizes the current state of microfluidic-based POC devices for heavy metal sensing and suggests potential future directions.

Methodology

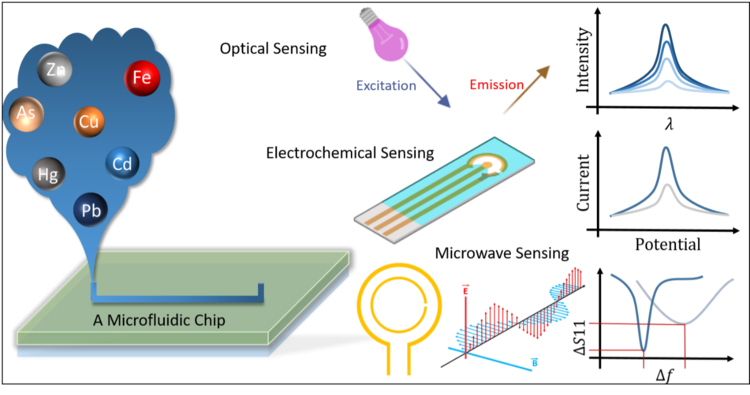

This review identifies and discusses heavy metal detection methods that integrate microfluidics with optical, electrochemical and microwave sensing systems for improved sensitivity and specificity (Figure 1).

Figure 1: Integration of microfluidics with conventional methods for heavy metal detection

Outcomes

Most reported POC systems sensed heavy metals in the form of ions, whereas in nature these metals are in the form of organic complexes where samples require pre-treatment. Microfluidics offers potential for sample preparation using a network of microchannels in addition to other advantages such as reduced reagent use, increased multiplexing and sensitivity and shortened analysis time. In general, microfluidic-based POC systems for metal sensing have a lower specificity as compared to traditional laboratory-based methods and therefore are best suited for early warning.

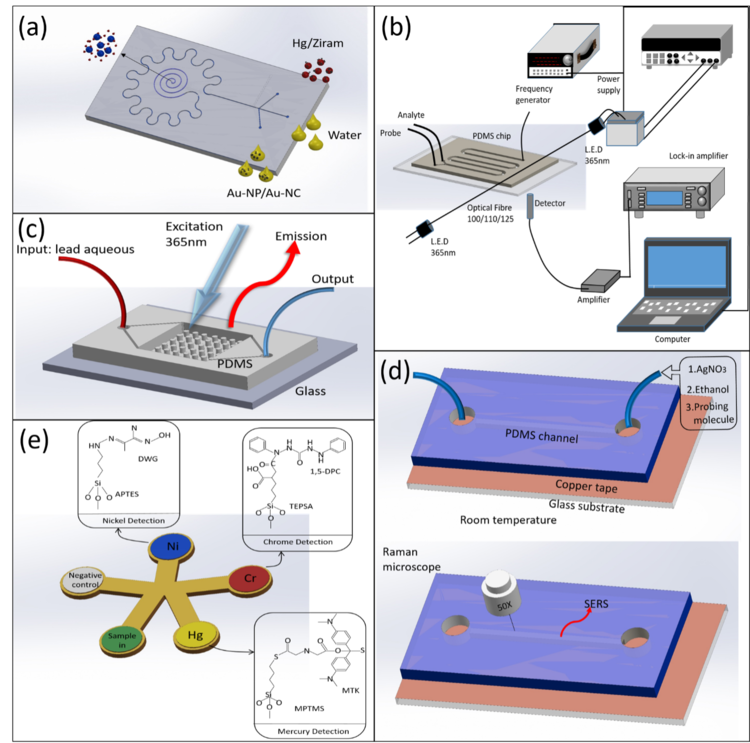

Significant efforts have been made to integrate microfluidics with optical methods such as fluorescence spectroscopy, surface-enhanced Raman spectroscopy (SERS) and colorimetric methods because they provide a very good sensitivity and specificity in differentiating heavy metals. A method utilizing gold nanoparticles (Au-NPs) and gold nanoclusters (Au-NCs) to detect mercury in a microfluidic-based system has been developed (Figure 2a). Several methods determined lead concentrations by using fluorescent sensing, including one method that used specific DNAzyme in a Polydimethylsiloxane (PDMS) microchip and another that detected lead using a fluorescent Calix-DANS4 sensor in a microfluidic device (Figure 2b). A new molecular fluorescent sensor containing three complexing dansyl fluorophores (Calix-DANS3-OH) to detect lead was identified. This work grafted the florescent Calix-DANS3-OH sensor on a microfluidic device through covalent bonding by making use of the inert siloxane bonds of PDMS simplifying operational procedures and channel design (Figure 2c). Surface-Enhanced Raman Spectroscopy (SERS) is a surface-sensitive technique that can enhance Raman scattering by using materials with nanostructures or molecules adsorbed onto rough metal surfaces. A microfluidic platform allowing on-chip synthesis of silver nanostructures and SERS detection of mercury that amalgamated on the Ag-NPs was reported (Figure 2d). A droplet microfluidic system integrated with SERS for the detection of mercury using Au-NPs functionalized with Rhodamine B was also presented offering additional advantages such as fast mixing, controllable operating conditions and cross contamination minimization.

Figure 2. Schematic of optical methods with microfluidic devices. (a) Microfluidic system for mercury detection using gold nanoparticles (b) Microfluidic chip to detect lead using optical fiber (c) Microreactor with grafted fluorescent sensors (d) SERS in a microfluidic chip with chip synthesis of silver nanostructure, and (e) Paper-based microfluidics with surface modification for different heavy metal detection

Colorimetric detection methods produce colours in samples that can be observed and measured. Several investigated the detection of nickel, chromium and mercury by using a chemically patterned paper-based microfluidic device where silane compounds were immobilized on the channel surface to covalently bind with colorimetric reagents that are specific to different metal ions. Some colorimetric methods were used for direct observation without any additional sensing, for example one paper discussed a simple, portable microfluidic device capable of detecting lead using a water drop as a magnifier.

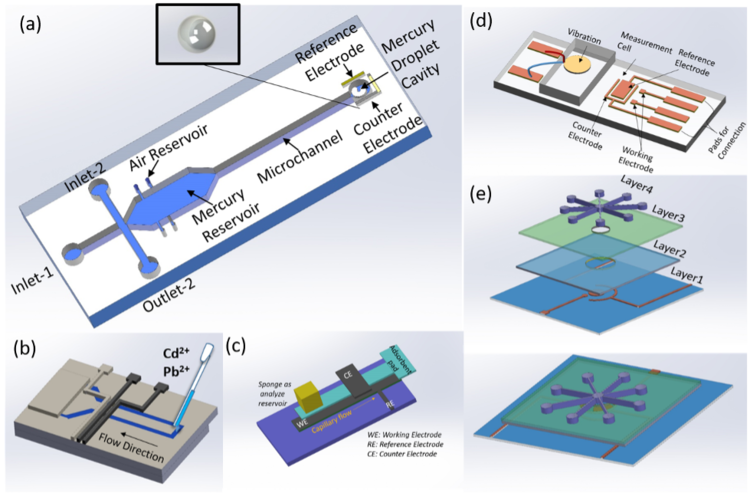

Electrochemical sensing methods integrated with microfluidic systems offer the advantage of being potentially very compact and significant efforts have been made to develop such systems. Electrochemical sensing often uses three electrodes including a working electrode, a reference electrode and a counter electrode where a mercury electrode was commonly used for heavy metal detection due to its high sensitivity. A microfluidic chip that can produce on-chip mercury droplet as the working electrode for cadmium and lead detection was reported (Figure 3a). Due to the toxicity of mercury, other eco-friendly electrodes such as bismuth were developed and integrated with microfluidic systems for the detection of cadmium, lead, and copper. Silver-based electrodes are an alternative with the potential to increase device reusability. Boron doped diamond electrodes have advantages including low background current and a wide window of electrical potential.

Advancements in printed electronics have catalyzed the development of POC electrochemical sensing applications. Inkjet printing has been used in planar electrodes fabrication and to make three electrodes with carbon, silver, silver/silver chloride onto a polyethylene terephthalate substrate to offer a rigid and durable platform with a low cost. Several papers discussed paper-based electrochemical sensing devices integrated with screen printed electrodes to detect lead and cadmium that were designed to allow on-chip sample filtration (Figure 3b). One method used a modifier free and sensitive microfluidic carbon-based electrochemical sensing method to detect cadmium and lead (Figure 3c), while another used a microfluidic sensing system integrated with a vibration motor to reduce the ion deposition time (Figure 3d). A microfluidic device with radially structured channels that increased the analyte volume for pre-concentration was presented (Figure 3e).

Figure 3. Schematic of electrochemical methods with microfluidic devices. (a) Microfluidic chip allowing on-chip generated mercury droplet working electrode (b) Paper-based device for electrochemical sensing (c) Paper-based microfluidic electrochemical carbon-based sensor (d) Microfluidic system with a motor for vibration and three electrodes for electrochemical sensing heavy metals (e) Multi layered microfluidic devices with radial structure for arsenic sensing.

In recent years microwave sensing has emerged as a promising method that can be integrated with microfluidic systems for various applications. A novel approach to detect zinc in water by using a planar microwave sensor with screen-printed coating has been reported.

Conclusions

Heavy metal pollution is a pervasive global concern with significant environmental and human health impacts. Although many methods have been developed for monitoring heavy metals in water, soil, air and food, most of these methods require sample transportation, centralized facilities and highly trained personnel. Heavy metals are often present in complex forms and low in concentrations, which require sample preparation for detection. Microfluidic platforms offer potential for integrating different sensing methods with sample preparation in POC applications.

Many microfluidic systems integrated with optical, electrical and electrochemical methods for heavy metal sensing have been developed. Although significant progress has been made, these systems are not yet widely deployed for POC applications. Many existing microfluidic-based systems are validated with prepared samples, whereas real-world samples are complex. Methods need to be validated with field water samples which will require development of functionalized materials that can be incorporated in microfluidic systems and identify specific metal ions. Additional sample processing functions should also be integrated with microfluidic systems, for example sample preconcentration and filtering using either mechanical, electrical, chemical or a combination of these methods. Finally, many existing systems remain bulky and expensive for POC applications, thus further miniaturization is critical.

Reference

Cui, W., Re, Z., Song, Y., Ren, C. (2022). Development and potential for point-of-care heavy metal sensing using microfluidic systems: A brief review. Sensors and Actuators: Physical. Volume 344. https://doi.org/10.1016/j.sna.2022.113733

For more information about WaterResearch, contact Julie Grant.