If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

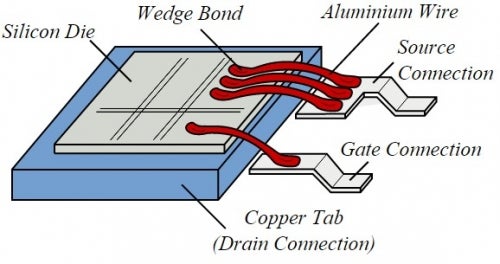

In today’s advanced electrical technology, it has become a necessity to use compact semiconductor chips in a variety of applications including computers, electrical appliances, and automobiles. This creates a need for more sophisticated electrical packages. Wire bonding is used to make interconnections between integrated circuits (IC), other semiconductor devices, and their packages. Because of its wide applicability, reliability of wire bonding in power electronics is a subject of critical interest for many companies and laboratories. In the last decade, reliability problems of thick bonding wires have been studied and are considered critical for power modules. The current flow through the bonding wire induces Joule heating which results in thermomechanical stress. Research groups at the University of Waterloo, including the Centre for Advanced Materials Joining (CAMJ) and the Nano and Micro Systems Laboratory (NMSL), are currently studying failure mechanisms of bonding wire.

Turker Dagdelen, a graduate student at the University of Waterloo, modelled the electro-thermal stress of a curved bonding

wire, Figure 1, as part of his Master’s Thesis.

Figure 1: Wire bonding schematic diagram

The teaching objectives for this case study are for students to conduct a force analysis of electrical structural components, to

understand equilibrium of deformable bodies, and to apply stress and strain concepts to a real world problem.

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.