If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

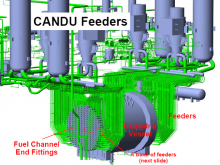

Babcock & Wilcox Canada Ltd. is located in Cambridge, Ontario. The company deals with many clients within the nuclear power industry including CANDU® reactor parts suppliers. The CANDU® reactor system contains feeder pipes which are part of the primary heat transport system (PHTS). This system encompasses the pipes and vessels that the heavy water passes through as it travels from the pressure tubes in the reactor, which contain the nuclear fuel, to the steam generators, where the energy in the heavy water is transferred to the light feed water, and back again. The energy entering the feed water causes it to increase in temperature, which in turn leads to the formation of steam. During the process of the heavy water travelling through the outlet feeder pipes, iron from the pipes corrodes into the heavy water, causing the pipe wall to thin over time. Therefore, it has become necessary to generate repair or inspection procedures for this type of degradation.

Babcock & Wilcox Canada Ltd. is located in Cambridge, Ontario. The company deals with many clients within the nuclear power industry including CANDU® reactor parts suppliers. The CANDU® reactor system contains feeder pipes which are part of the primary heat transport system (PHTS). This system encompasses the pipes and vessels that the heavy water passes through as it travels from the pressure tubes in the reactor, which contain the nuclear fuel, to the steam generators, where the energy in the heavy water is transferred to the light feed water, and back again. The energy entering the feed water causes it to increase in temperature, which in turn leads to the formation of steam. During the process of the heavy water travelling through the outlet feeder pipes, iron from the pipes corrodes into the heavy water, causing the pipe wall to thin over time. Therefore, it has become necessary to generate repair or inspection procedures for this type of degradation.

The teaching objective for this case study is the design of a demonstration loop, including need analysis, conceptual design, preliminary design and detail design analysis.

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.