Aviation parts made one at a time, any time, just in time

3D printing technology is perfect fit with new Waterloo Institute for Sustainable Aeronautics

3D printing technology is perfect fit with new Waterloo Institute for Sustainable Aeronautics

By Brian Caldwell Faculty of EngineeringWith its present ability to deliver high-value, low-volume parts and components, additive manufacturing (AM) is a perfect fit for the specialized needs and demands of the aeronautics industry.

Projects and research related to aeronautics already account for about 25 per cent of work at the Multi-Scale Additive Manufacturing (MSAM) Lab at Waterloo Engineering, and leaders there see even more opportunities ahead with the scheduled launch on Oct. 5 of the new Waterloo Institute for Sustainable Aeronautics (WISA).

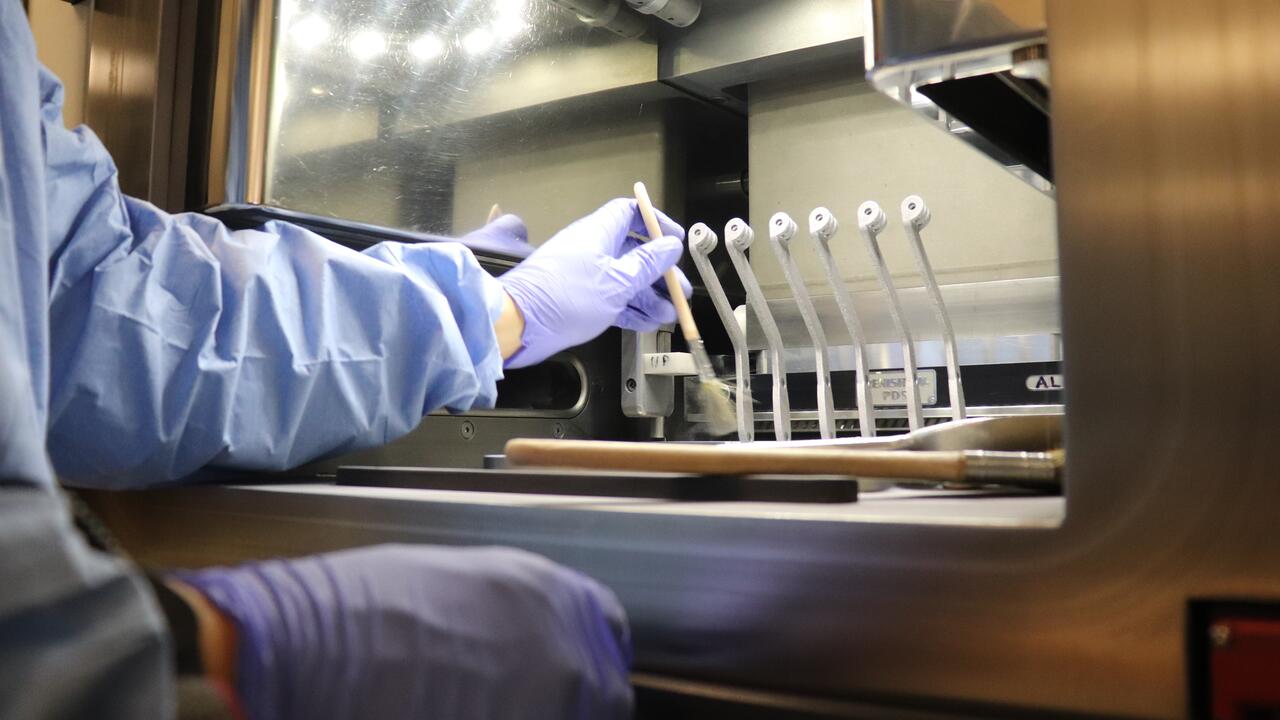

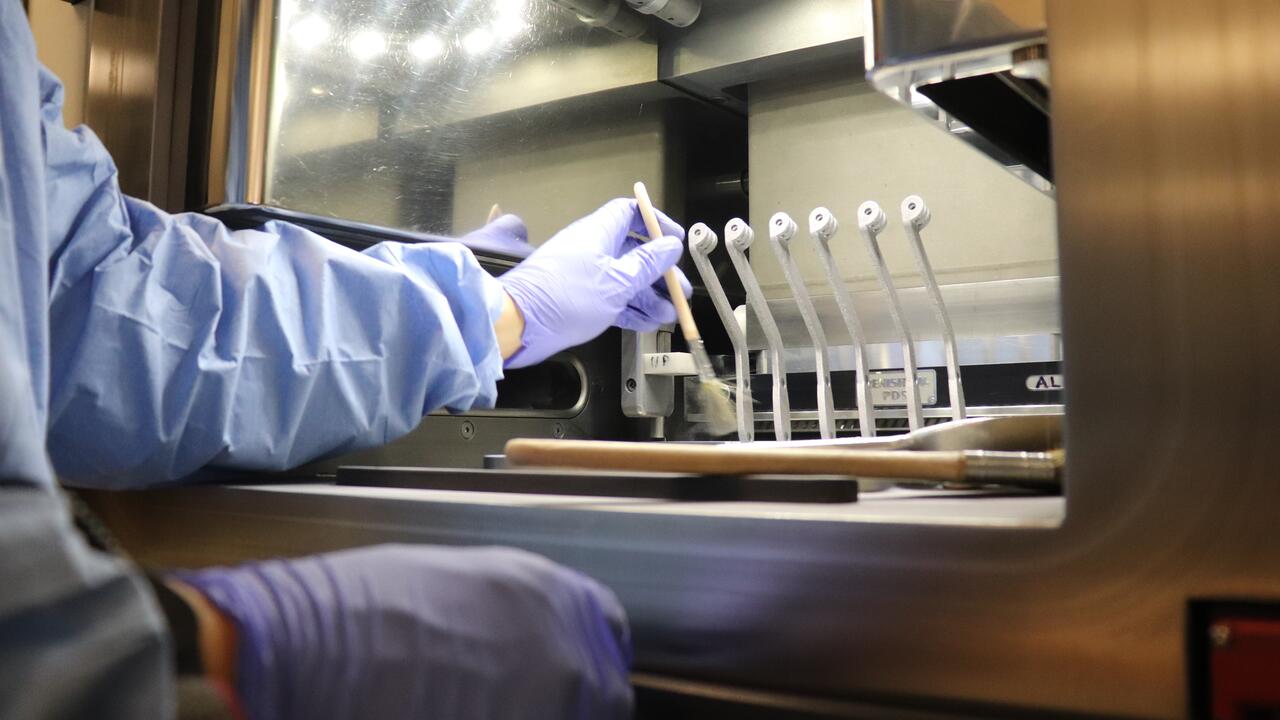

The video above chronicles the production of custom, aerodynamic metal parts for the Canadian Olympic cycling team, from digital design to 3D printing, using an additive manufacturing process known as laser powder bed fusion at the MSAM Lab at Waterloo Engineering.

“AM adoption started in the biomedical and aerospace/aviation fields and they’re still the main drivers,” said Mihaela Vlasea, associate research director at MSAM and a professor of mechanical and mechatronics engineering at the University of Waterloo.

Also known as 3D printing, AM offers tremendous design freedom because parts are precisely built up layer-by-layer rather than cut out of blocks of material or produced via forming processes in traditional manufacturing approaches.

That means parts can be customized and optimized to boost efficiency, performance and longevity, limiting waste and reducing weight, for instance, so aircraft require less fuel.

“By virtue of the additive manufacturing technology, you have the ability to build parts one unit at a time,” said Vlasea, a member of WISA. “You can functionalize components at the design level as well as at the material system level. This allows you to produce new optimized components that you literally couldn’t build using conventional manufacturing.”

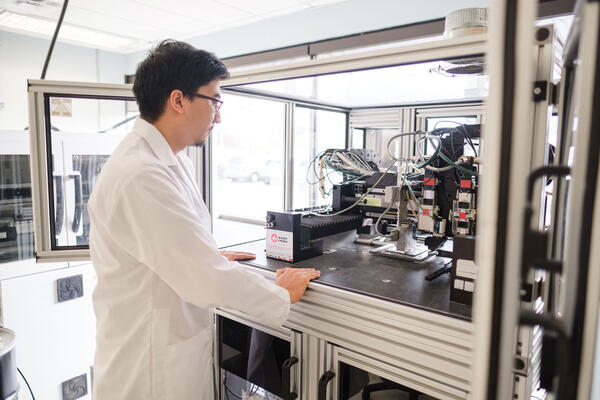

Mihaela Vlasea is associate research director of the Multi-Scale Additive Manufacturing (MSAM) Lab and a member of the new Waterloo Institute for Sustainable Aeronautics (WISA).

In the case of aging aircraft, the technology enables the manufacture of innovative and customized components to optimize functionality. It can also address replacement parts that are no longer mass produced, dramatically reducing costs and increasing efficiency.

With a focus on metal AM, the growing Waterloo MSAM lab – it has almost doubled in size in the last 18 months – is actively involved in optimized design and manufacturing of parts for propulsion and thermal management, including complex, hidden cooling channels and other features.

It has also developed particular expertise in determining how to use new metal powders – the raw materials of metal AM – including high-strength aluminum alloys, titanium alloys and nickel superalloys.

“We’re striving to be the go-to lab in Canada if someone has a new alloy in aerospace that they want to test and print into functional products,” Vlasea said.

To ensure highly specialized, expensive parts made with AM are up to the job, the lab uses a variety of machine sensors and characterization techniques to detect potential problems before they are actually deployed.

And to reduce waste, and therefore costs, as much as possible, MSAM researchers are working with experts at the Natural Sciences and Engineering Research Council on the best ways to reuse and recycle metal powders left over after printing.

It all adds up to better aeronautics parts that also save money and resources, boosting the economy while also reducing environment impacts via benefits such as lower fuel requirements and shorter supply chains.

“The new institute is a terrific way of consolidating competencies across campus such that we can effectively communicate with other researchers and engage in opportunities that might not be available if we remained fragmented, including high-level, collaborative grants,” Vlasea said.

Main photo: A technician at MSAM removes aerodynamic metal parts that were custom-made for the Canadian Olympic cycling team using a process known as laser powder bed fusion.

Read more

Waterloo lab helps fill industry demand for additive manufacturing skills

Read more

Combining machine learning techniques with real-world scenarios to combat forest fires

Read more

The University of Waterloo will be a key partner with leading Canadian companies and sectors chosen to help grow our country’s global competitiveness through significant investments in the areas of artificial intelligence (AI) and advanced manufacturing

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.