Reference

10240

Patent status

#63/577,864 by the USPTO

Stage of development

Prototype

Contact

Scott Inwood

Director of Commercialization

Waterloo Commercialization Office

519-888-4567, ext. 43728

uwaterloo.ca/research

Background

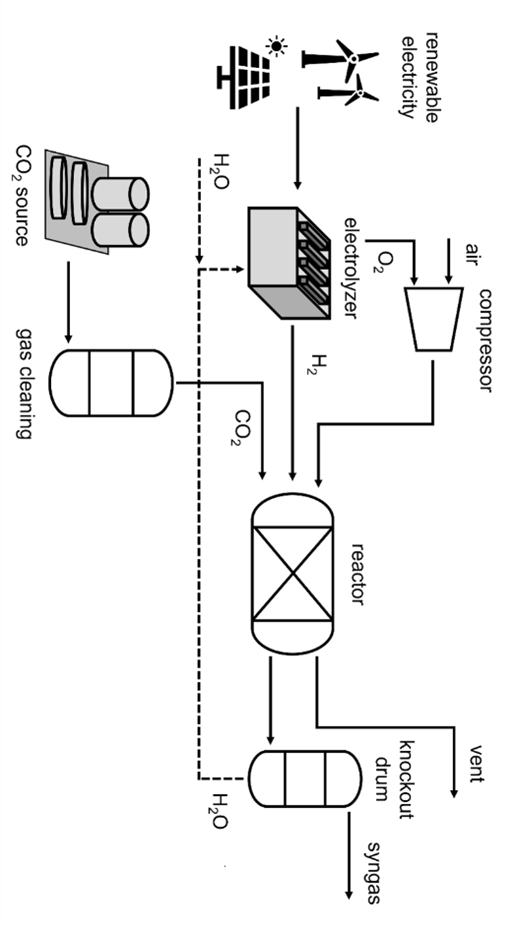

From technological, societal, and political perspectives, the optimization of energy utilization, reduction of carbon dioxide (CO2) emissions, and mitigation of global environmental challenges have emerged as paramount concerns. Thus there is a growing market and urgent need for CO2 capture and utilization, and large-scale thermocatalytic conversion of captured CO2 holds promise. Sustainable syngas production from captured CO2 via reverse water gas shift (RWGS) circumvents the high energy requirement associate with fossil fuel-based production represents and thus represents a favorable alternative to conventional methods. Furthermore, the volatility in feedstock prices underscores the importance of adopting alternative production methods that promote diversity and stability.

Description of the invention

The technology disclosed consists of two parts.

The first part is a process of converting CO2 to synthesis gas via thermocatalytic hydrogenation which is a process of reacting CO2 with H2 over a catalytic bed at elevated temperature (above 500 ℃).

The second aspect of the technology utilizes a thermally coupled reactor that combines catalytic hydrogen combustion (CHC) with RWGS reaction in a single device.

Advantages

A low-cost, compact and efficient single-unit reactor design. CHC allows for safe and relatively low temperature (but still over 500 ℃) hydrogen oxidation. The two reactions (CHC and RWGS) are not separated in time, thus allowing for efficient heat transfer. The integrated CHC-RWGS process allows for utilization of electrolytic oxygen (O2), which is typically vented (wasted) in electrolysis systems.

Potential applications

The market opportunity for this technology targets the industries that utilize captured CO2 or/and require syngas as a feedstock. The range of target markets is diverse and includes, but is not limited to:

- Carbon capture and utilization.

- Chemical manufacturing: using this technology to produce new chemicals or to replace traditional feedstocks, such as methanol, ethanol, wax, fertilizers, etc., using syngas as a feedstock

- Energy storage: conversion of CO2 using renewable energy sources as a means of electricity storage as chemical energy.