To develop efficient structural steel joints using robotic Wire Arc Additive Manufacturing

Materials Science & Engineering

Natural Sciences and Engineering Research Council of Canada (NSERC)Description

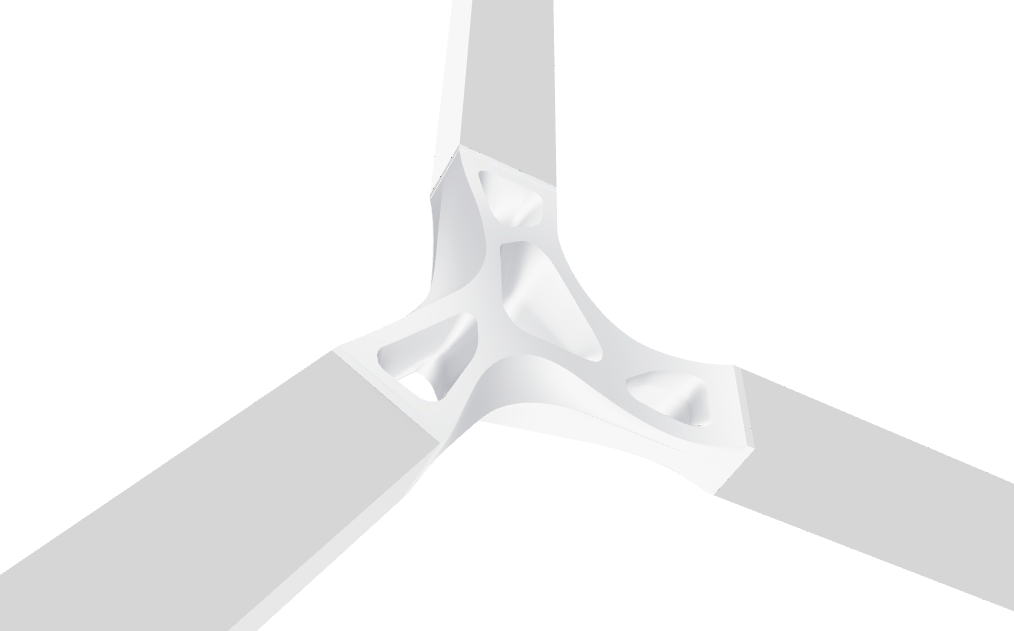

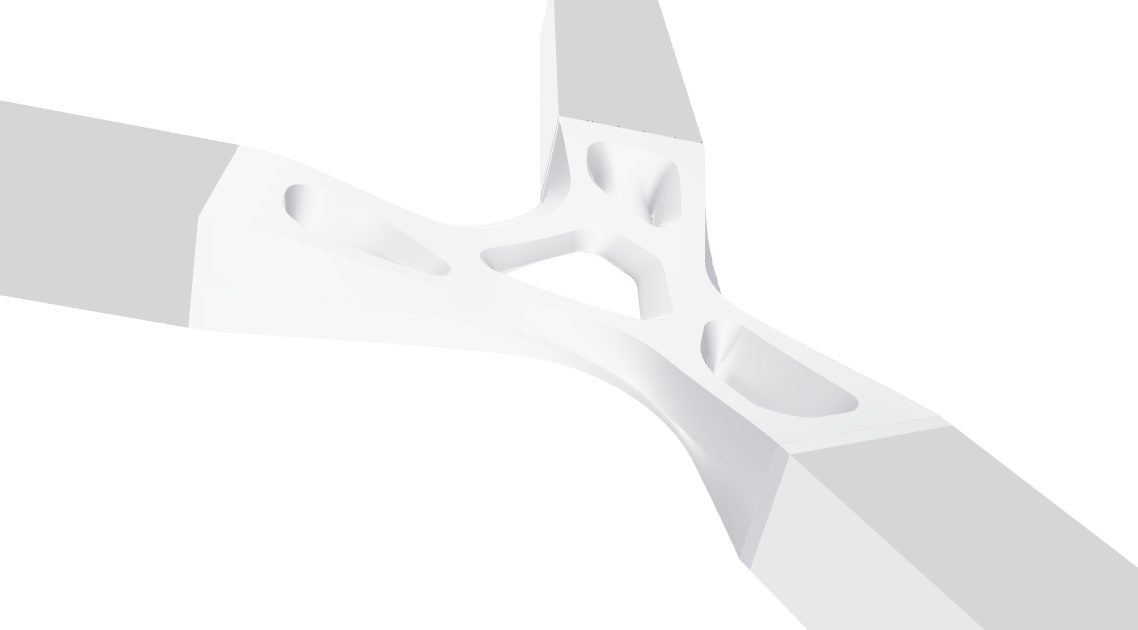

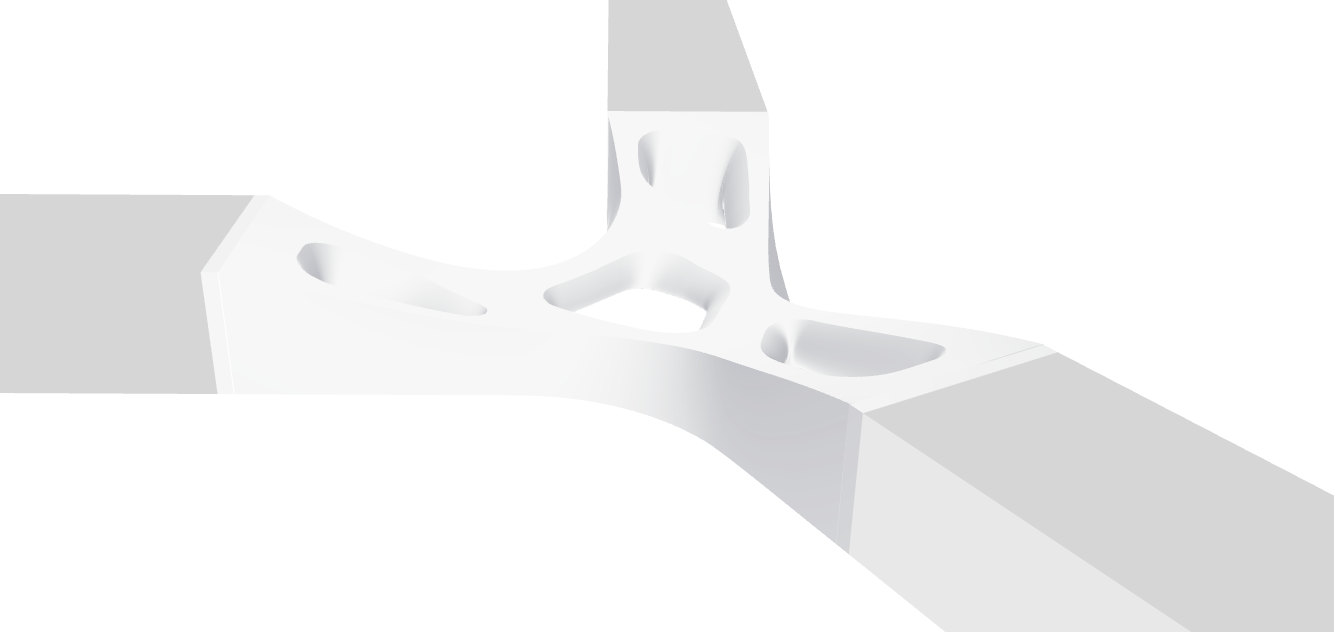

Structural joints are a critical component in design that determines the success factor of any architectural project. While typical joints at a smaller scale have been mastered in the construction industry, developing unique structures in a larger context with custom joinery often creates challenges with accuracy, efficiency, and manufacturing cost. An alternative to conventional techniques is Additive Manufacturing, which can efficiently develop optimized and intricate structural components while adhering to time and budget constraints. The project focuses on developing small-scale prototypes of the iterations to eliminate any design ambiguities, selecting the most efficient design in terms of aesthetics and structure, as well as manufacturability using the available hands-on technology of Wire Arc Additive Manufacturing (WAAM) with six-axis using robotic arm, to test the structural integrity of each joint through stress tests. This process would aid in new possibilities of structural design to understand how different typologies of joints impact structural performance while not limiting design possibilities.