Physics-Informed Neural Networks for Electrochemical Systems

This research area focuses on the development of Physics-Informed Neural Networks (PINNs) and data-driven discovery frameworks to decode complex interfacial phenomena. By embedding partial differential equations (PDEs) directly into the neural architecture, we eliminate the need for massive labeled datasets while ensuring that model predictions remain physically consistent. This approach allows us to solve intricate conservation and transport equations at the electrochemical interface that were previously computationally prohibitive or mathematically "unsolvable" via traditional numerical methods.

Beyond simulation, we leverage Sparse Regression and Symbolic Learning to transform raw experimental data—such as Cyclic Voltammetry (CV) and Electrochemical Impedance Spectroscopy (EIS)—into human-readable physical laws. Rather than fitting data to rigid, pre-defined empirical models, our methodology "discovers" the governing equations from a library of physical basis functions. This transition from "black-box" AI to interpretable, closed-form equations provides the mechanistic insight necessary to design the next generation of corrosion-resistant materials and ultra-long-life energy storage systems.

Key Research Topics

1. Physics-Informed Neural Solvers for Electrochemical Systems

This research focuses on solving the mathematical equations (PDEs) that govern electrochemical systems without needing massive experimental datasets. By embedding physical laws directly into the neural network's learning process, we aim to uncover the hidden mechanisms behind corrosion, electrocatalysis, fuel cells, and batteries. This approach allows for high-fidelity modeling of how atomic-scale structural changes affect macroscopic performance, bridging the gap between chemistry and large-scale engineering.

2. Data-Driven Discovery of Degradation Laws

Instead of assuming how a battery or fuel cell will wear out (such as simple power-law fades), this research seeks to discover the actual mathematical laws of degradation. Using sparse regression and interpretable AI, we extract clear mathematical formulas from noisy experimental data, such as Cyclic Voltammetry (CV) or Electrochemical Impedance Spectroscopy (EIS). This work targets the "missing math" behind lithium plating, catalyst clumping, and resistance growth, providing a clear predictive roadmap for extending device lifetimes.

3. Neural Multiphysics of SOEC/SOFC Interfaces

We develop specialized PINN architectures to model how ions and electrons move across the interfaces of Solid Oxide Electrolyzer Cells (SOEC) and Fuel Cells (SOFC). These models account for how local electricity flow and chemical reactions influence transport behavior. A major focus is predicting cation interdiffusion—the slow mixing of materials at the interface—which causes performance to drop over thousands of hours. By training the AI on these physical principles, we can predict long-term degradation that traditional models often miss.

4. Scalable Natural Gradients for Large-Scale PINNs

This topic addresses the "speed limit" of training high-accuracy physics-informed networks. While Natural Gradient methods are much more accurate than standard tools like ADAM, they are usually too slow and memory-heavy for large problems. We use "sketching" (a randomized math technique) to create a compressed, high-speed version of the optimization process. This allows us to train PINNs with millions of parameters in minutes rather than hours, making it possible to solve the complex, high-frequency physics problems found in real-world electrochemical systems.

Machine Learning Interatomic Potentials (MLIP) & Atomic-Scale Dynamics

This research area focuses on the development and deployment of High-Fidelity Neural Network Potentials to simulate materials under extreme chemical and mechanical environments. By utilizing GPU-accelerated architectures—such as Charge Recursive Neural Networks (QRNN) —we achieve the predictive accuracy of ab initio quantum mechanics at a fraction of the computational cost. This enables us to explore material behaviors that are inaccessible to traditional empirical force fields, specifically focusing on complex molten salt chemistry, polycrystalline interfaces, and the high-temperature kinetics critical to the next generation of nuclear and energy storage technologies.

Central to our methodology is the use of Equilibrium and Non-Equilibrium Molecular Dynamics (NEMD) to extract macroscopic transport coefficients. We investigate how atomic-scale defects, grain boundaries, and reactive impurities govern the flow of heat, mass, and charge. By integrating these ML-accelerated simulations into production frameworks like LAMMPS , TorchSim and nvalchemi-toolkit-ops, we provide a quantitative, atomistic grounded toolkit for predicting corrosion, ion conduction, and structural failure in systems where empirical models traditionally fail.

Key Research Topics

1. ML-Accelerated Transport & Corrosion in Molten Salt Environments

This research tackles the extreme chemical challenges found in Small Modular Reactors (SMRs). We develop machine learning potentials to simulate FLiNaK molten salts, focusing on how aggressive fluoride chemistry and impurities cause corrosion at the surfaces of structural alloys. By using advanced statistical methods (Green-Kubo and NEMD), we calculate critical properties like viscosity, thermal conductivity, and how quickly impurities move across the entire reactor operating range. This provides a solid scientific foundation for improving nuclear safety and ensuring materials last longer in harsh environments.

2. Ion Kinetics in Polycrystalline & 2D Material Networks

This topic investigates how ions move through complex materials like graphite, 2D-nanostructured materials, and solid electrolytes. Because ions crossing "grain boundaries" (the borders between microscopic crystals) is a rare event that standard simulations often miss, we use AI-accelerated dynamics to capture these movements. Our goal is to understand how defects and crystal alignment impact ionic conductivity, which could lead to a breakthrough in fast-charging protocols for the next generation of lithium-ion batteries.

Advanced Statistical Mechanics & Neural Functional Theory

This research area centers on the development of Classical Density Functional Theory (cDFT) frameworks to predict the microscopic structure and thermodynamic properties of inhomogeneous fluids. We bridge the gap between rigorous statistical mechanics and practical engineering by introducing Conditional Neural Functionals. By parameterizing Fundamental Measure Theory (FMT) with spatially-varying, neural-network-derived fields, our approach allows the grand potential functional $\Omega[\rho]$ to adapt to local structural features. This enables the precise modeling of complex phenomena—such as unconstrained crystallization and polymorphic transitions—that have historically remained computationally unstable or numerically inaccessible.

Furthermore, we extend these equilibrium foundations into the time domain through Dynamic Density Functional Theory (DDFT). By coupling the Nernst-Planck transport equations with cDFT-derived chemical potential gradients, we account for non-ideal effects—such as ion correlations and steric (size) exclusions—that standard continuum models ignore. This multiscale approach, accelerated by massively parallel GPU architectures , provides a high-throughput engine for the inverse design of nanoporous materials and the prediction of ion kinetics in next-generation electrochemical devices.

Key Research Topics

1. Neural-Enhanced FMT for Crystallization and Polymorphism

Traditional mathematical models for how liquids turn into crystals often suffer from numerical instability. We overcome this by using a Conditional Neural Functional approach to Fundamental Measure Theory (FMT). By using AI to analyze the local density of atoms, we can clearly distinguish between bulk liquids, interfaces, and the "seeds" of new crystals. This allows us to study how droplets take shape on water-repellent surfaces or how specific crystal structures form spontaneously. This tool is essential for predicting polymorphic behavior—how the same material can take on different solid forms—in complex fluids.

2. GPU-Accelerated Screening and Inverse Design of Nanoporous Media

To speed up the discovery of materials for gas storage and carbon capture, we developed a GPU-native software that reduces calculation times by over 100 times. This allows us to rapidly generate high-accuracy "adsorption maps," which show how gases stick to surfaces, far faster than traditional molecular simulations. This platform acts as a high-speed "screening engine" to scan vast databases of materials and provides the data needed to reverse-engineer custom materials tailored for specific gas separations.

3. Non-Equilibrium Ion Transport and EDL Dynamics

We develop advanced models to resolve the complex "wave-like" patterns of ions and the charging speed of the Electric Double Layer (EDL). Unlike standard equations, our models capture how ions behave at very high voltages and in tiny spaces where they are tightly packed. This is critical for preventing contamination in fuel cells and optimizing the charging rates of supercapacitors. Our work explains how ions move in narrow pores where traditional liquid theories no longer apply.

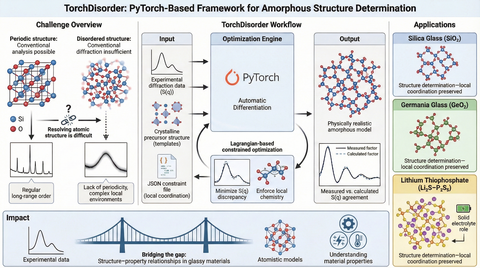

Gradient-Based Structural Refinement & Disordered Systems

This research area addresses the "missing link" in materials characterization: the precise determination of atomic arrangements in amorphous and disordered solids. Unlike crystalline materials, disordered systems—such as glasses and solid electrolytes—lack long-range periodicity, making them difficult to resolve using standard diffraction. We bridge this gap by replacing traditional, slow stochastic methods (like Reverse Monte Carlo) with automatic differentiation and gradient-based optimization. Using our open-source framework, TorchDisorder, we treat atomic positions as optimizable parameters within a PyTorch-based Lagrangian manifold. This allows us to rapidly minimize the discrepancy between experimental scattering data and theoretical models while simultaneously enforcing complex chemical constraints.

Key Research Topics

1. Constrained Optimization of Amorphous Energy Materials

We focus on resolving the 3D structures of glass systems critical to next-generation energy technologies, including solid electrolytes. By utilizing the Cooper library for Lagrangian-based optimization, we can enforce chemically realistic environments—such as tetrahedral or octahedral coordination—without manual parameter tuning. This ensures that the resulting structural models are not only mathematically consistent with experimental data but also physically viable for downstream simulations of ion transport and mechanical stability.

2. Differentiable Physics for Experimental Structural Discovery

This topic explores the integration of "differentiable physics" into the materials characterization pipeline. By generating configuration files from crystalline precursors, we automatically extract local coordination geometries and apply them as constraints on disordered systems. This framework enables the high-throughput generation of structural models for amorphous anodes and solid-state electrolytes, providing a more accurate starting point for the machine learning interatomic potentials (MLIP) and density functional theory (cDFT) workflows used elsewhere in the group.