Contributors: Weijia Cui, Zhe Ren, Carolyn L. Ren

Microfluidics enable great reduction in reaction time and sample use which have been used in many areas. The combination of microwave technique and microfluidics can realize sensing and heating functions in the system which provides more potential for the use of microfluidics in materials and biochemical applications. Multiplex microwave system in a typical microfluidic device can realize microwave sensing and heating simultaneously and microwave sensing can guide the heating process through a backstage system to realize selective microwave heating.

Microwave sensing

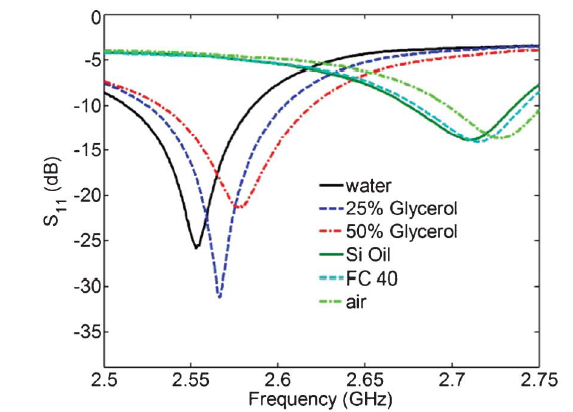

Microwave sensing in our microfluidic system can be used to identify droplet contents, concentration or rate. The main component of the microwave sensing is a microwave resonator which is capable to differentiate droplets with different electrical properties including permittivity and conductivity. Different materials passing through the resonator area cause a resonance frequency shift or magnitude change of S11 parameter, which can be related to the droplet information. Microwave technique can realize non-contact, label-free and fast droplet sensing. Our group has demonstrated droplet microwave sensing in a microfluidic chip (Boybay 2013) and further improved by achieving high throughput droplet sensing in KHz rate (Yesiloz 2015).

Resonance frequency shift of different materials in the microchannel.

Microwave heating

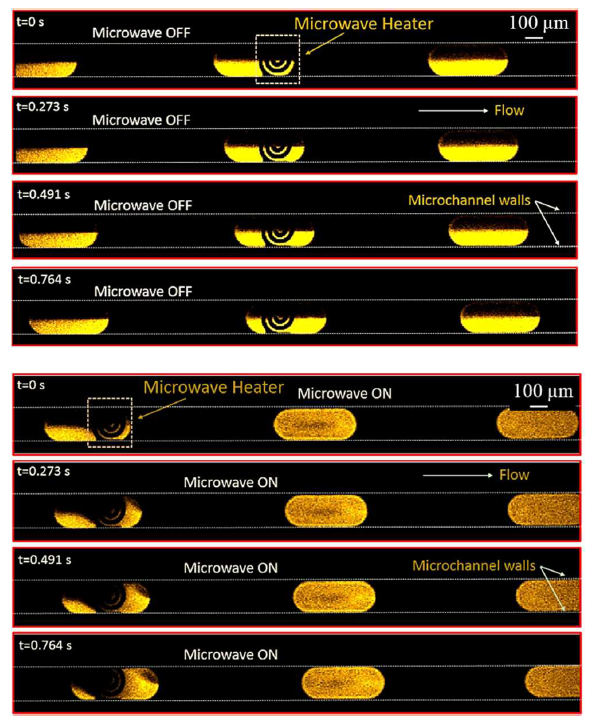

Many microfluidics based applications require heating process to manipulate the motion of droplets such as droplet generation, mixing, or merging, and also some reactions requiring energy to initialize also rely on the droplet heating. Microwave is a good candidate to be used for heating droplets, which attributes to its fast heating rate and localized heating properties. Droplet with known content can be heated by delivering microwave power at certain frequency, while leaving surrounding different materials unaffected. Our group has previously developed using microwave heating to induced droplet mixing (Yesiloz 2016).

Microwave induced droplet mixing when passing through resonator area.

Multiplex microwave function in a single microfluidic chips

Multiplex microwave system integrated on microfluidic device is desired which allowing us to realize microwave sensing and heating simultaneously. This simultaneous work can achieve microwave selective heating droplets, especially for droplets with unknown content, which is quite important for applications with complex samples. To construct this multiplex microwave system, at least two microwave resonators are required to deploy into a typical microfluidic device. One resonator is served as a sensor to acquire the information of unknown droplets for sensing purpose and another resonator is employed for heating purpose. A backstage interface is required to set up to transmit data from sensing result to heating resonator to selectively heat droplets.

Bibliography

[1] Boybay, Muhammed S., et al. "Microwave sensing and heating of individual droplets in microfluidic devices." Lab on a Chip 13.19 (2013): 3840-3846.

[2] Yesiloz, Gurkan, Muhammed Said Boybay, and Carolyn L. Ren. "Label-free high-throughput detection and content sensing of individual droplets in microfluidic systems." Lab on a Chip 15.20 (2015): 4008-4019.

[3] Yesiloz, Gurkan, Muhammed S. Boybay, and Carolyn L. Ren. "Effective thermo-capillary mixing in droplet microfluidics integrated with a microwave heater." Analytical chemistry 89.3 (2017): 1978-1984.