Fatigue is the process of progressive localized permanent change occurring in a material subjected to cyclic stresses and strains at some points which may result in crack nucleation and growth to final failure after a sufficient number of fluctuations. Alternations of stress and/or strains are difficult to avoid in many practical engineering situations and are very important in design. In many components such alternating stresses and/or strains are applied in a multiaxial manner with variety of load path patterns including in-and-out-of-phase. This interest has a broad range including automotive, aerospace, off shore structures, power generation, and microelectronics industries.

The Laboratory for Fatigue and Stress analysis (FATSLAB) is a laboratory in the Department of Mechanical and Mechatronics Engineering with three major goals:

- Fatigue characterization, modeling and life enhancement.

- The study and development of the robust and efficient methods for durability analysis and their applications to CAE design.

- The education of engineering leaders.

The current research thrust areas are: multiaxial fatigue of emerging light materials, durability of advanced joining, soild state additive manufacturing, cold spray coating, cyclic plasticity modeling of wrought alloys.

News

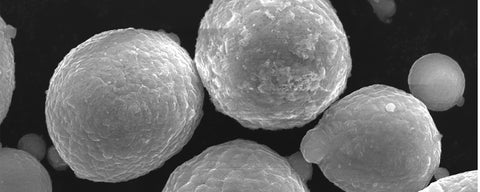

Erfan Azqadan paper just published in Acta Materialia

In a groundbreaking paper recently published in "Acta Materialia", researcher Erfan Azqadan presents a novel approach to material science through the application of machine learning. The paper, titled "A Niche Application of Machine Learning in Material Science: Generating Feature-Rich SEM Images", introduces an innovative method that could significantly enhance the capabilities of material scientists and engineers.

Celebrating the Success of MASc Graduates

A hearty congratulations to Jonathan Tang, Alan Woo, Jessica Zhang, Ibim Tolofari, and Gurmeet Gill for successfully completing their Master of Applied Science (MASc) degrees. Their perseverance and dedication through the challenges posed by COVID-19 restrictions are truly commendable. This accomplishment marks a significant milestone in their academic journeys and sets the stage for future professional achievements.

Innovating for the Future: Prof Jahed's $1.5M Grant for Remanufacturing Technologies

Professor Jahed has been awarded a significant grant of $1.5 million, marking a pivotal moment in the field of remanufacturing technologies. This grant, which is part of a larger $4 million federal funding initiative, will propel research and development in sustainable manufacturing practices. Professor Jahed’s visionary approach aims to revolutionize the industry, promising both environmental and economic benefits.