Designing a Sustainable Undergrad Organic Chemistry Lab

When I moved my laboratory due to rebuild of my floor, I accidentally ended up with equipment that would allow me to call my laboratory sustainable. This gave me great motivation to carry on in the pressures of this project and I sought a Green Lab certification from the Office of Sustainability. As of today, the lab is at the Silver level but I am hoping to reach Gold level by the time recertification occurs.

Obtaining the Green Lab certification at the University of Waterloo was fairly simple, here is how it works:

- Register as Green Labs Ambassador.

- Meet with the Green Programs Coordinator to do a walk through of the space to see opportunities to incorporate elements of the Green Labs program (happened within 1-2 weeks).

- Complete the Green Labs scorecard. Received within 1-2 weeks. Its completion took me roughly two hours.

- Receive reviewed score and hopefully celebrate your new Green Lab certification!

- Physical certificate handed out at the November Eco Summit.

I wanted to list here some of the equipment I purchased in order to achieve this level of certification. The ductless fume hoods would require significant investment and lead to higher consumables cost with the filter change so that would not be my priority. Using a vacuum network instead of water aspirators and a closed-loop system for condensers (either with a chiller or a fish pump) would be cheaper and easier to implement at first.

Equipment for a Sustainable Lab

Ductless Fume Hoods

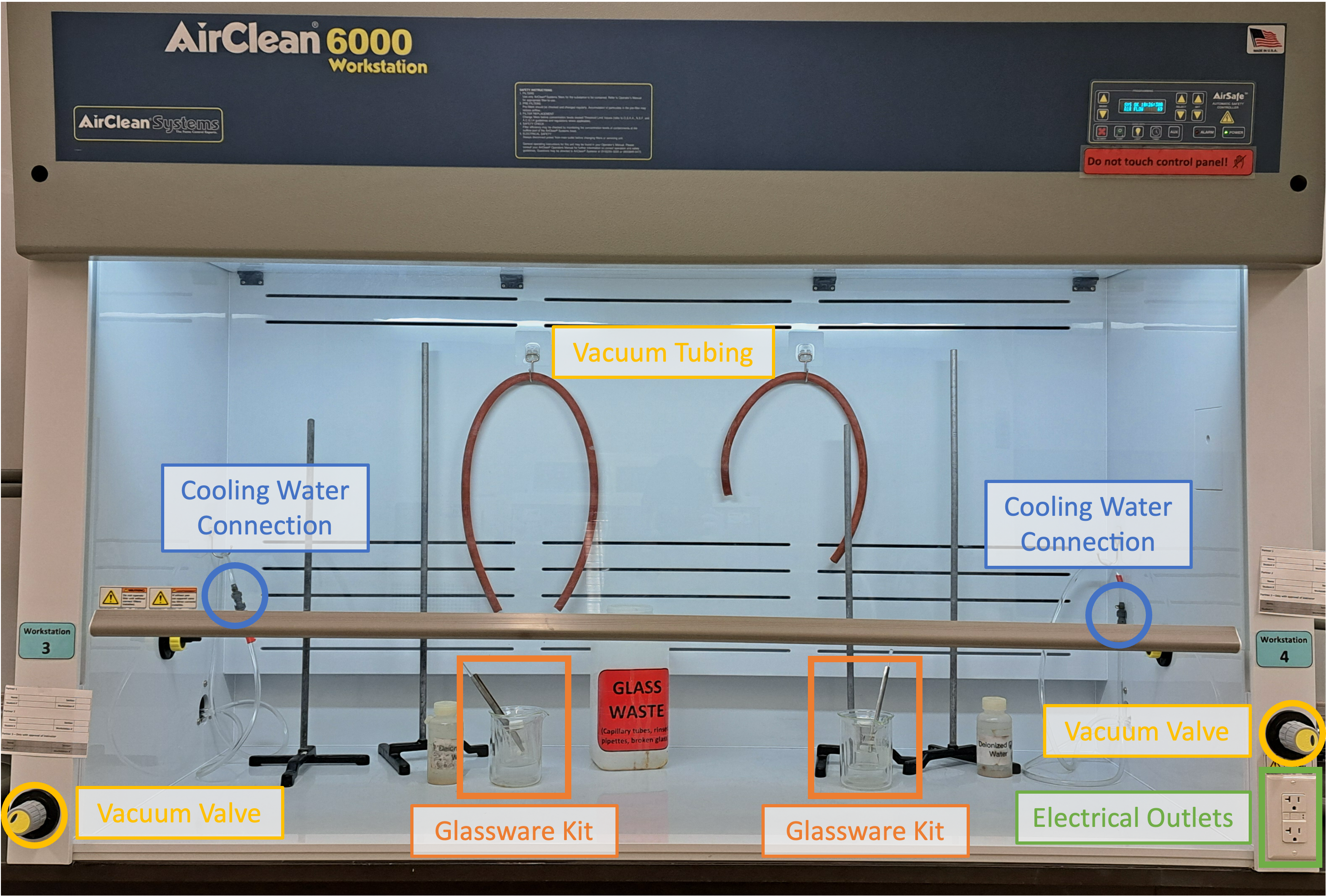

Air Clean AC6000S fume hood set up for undergraduate lab. There is one vacuum outlet on each side, along with the connections for the chilled water.

Ductless fume hood purchased from Air Clean Canada (model AC6000S with sliding sash) with funds from the Faculty of Science.

The fume hoods were placed on the benches after being modified to be fully flat. The hoods use a double stack of activated carbon filters and have a sensor for breakthrough of organic fumes as well as a pre-filter for dust and particulates. Filters are changed every year and the fume hoods have a count down to the date of replacement.

They have a utility port on each side (used to connect to the vacuum network), a pass through port on each side (used to pass through tubing from the chillers to connect to condensers) and one duplex outlet.

The sash height can be adjusted and there is a separate alarm for low air flow. Fume hoods can be turned on and off easily. I used retort stands instead of installing scaffolding to save time and cost but it has been working well.

After being used for two semester I am satisfied with these hoods. They are easy to clean and I have not noticed more organics smell than in my laboratory with ducted hoods. I would perhaps be more hesitant if I used highly toxic substances, but since I teach second-year organic chemistry for non-majors, I already avoid such species to reduce risks at the source.

Vacuum Network

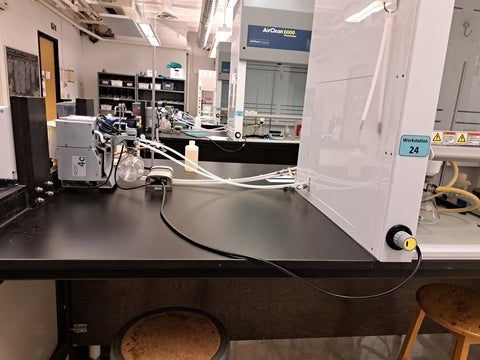

Set up of the vacuum network. Vacuubrand provides the plastic tubing and connectors to run vacuum lines to the fume hoods.

Vacuum pump used for the vacuum network at each bench. Eight workstations have their vacuum connected to one pump.

Vacuum network including pump (MD 4C NT +AK +EK model) purchased with funds from the Faculty of Science. Vacuubrand/Brandtech will use provided floor plans to draw the network design and price all parts needed (pumps, valves, connectors, tubing) based on usage and dimensions.

The dimensions of the perforations needed for the valve was provided to Air Clean to include on the drawing of the fume hood. Installation is fairly straightforward and was completed by Science Facilities.

The Vacuubrand pumps are top of the line and require no oil which means less consumables and maintenance. They operate at a higher temperature and evacuate fumes into the glass bulbs which are cleaned around two times a semester. The vacuum is very powerful at the fume hood: we can have eight vacuum filtrations at the same time and have only noticed loss of vacuum once. This was however a user issue, several of the valves were left fully open and taking in air. It is possible to install an additional valve to control the vacuum before it reaches the fume hoods to lower the suction, but we have not found this necessary.

Training students to use the vacuum valves is quite simple, below are the instructions provided to perform vacuum filtration:

- Clamp filter flask using the three-prong clamp.

- Connect the vacuum tubing (thick-walled) between the vacuum fixture inside the fume hood and the side-arm of the flask. Place a rubber adapter in the neck of the flask to provide a seal for the Buchner funnel.

- Place the Buchner funnel on top of the vacuum flask. Be careful not to knock down the assembly as the Buchner funnel is not held tightly until the vacuum is turned on.

- Add a filter paper inside the Buchner funnel and wet it with solvent making up the bulk of the solution filtered. A dry filter paper will not adhere to the Buchner funnel and solid could escape to the vacuum flask.

- Turn on the vacuum by turning the yellow dial counter-clockwise until you feel resistance and you see liquid pouring into the filter flask.

- Slowly pour the solution through the Buchner funnel. You can swirl the solution gently to suspend all the solution prior to pouring. Small volumes of solvent can be used to complete the transfer of the solid, or you can use a spatula to scoop it out.

- Once the separation of the liquid from the solid is completed and the solid is mostly dried, turn off the vacuum by turning the yellow dial clockwise. Remove the vacuum hose from the filter flask.

- Transfer your solid to a tared weighing paper or watch glass, scraping gently to release the solid from the filter paper without ripping the latter.

- The filter paper is then disposed in the solid waste.

Before the installation of the vacuum network, we used water aspirators for suction filtration which is wasteful of water and we can also pull a lot of organic fumes in the effluent.

Closed-loop Chiller System

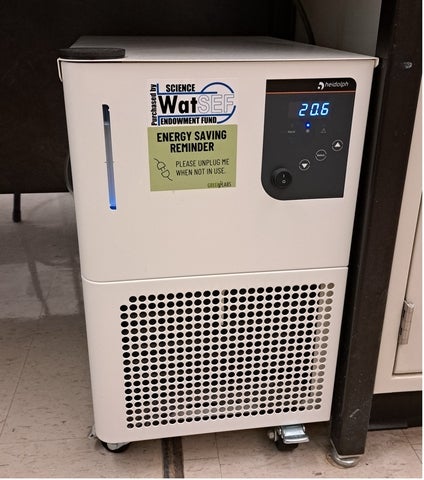

Hei-CHILL 600 unit under laboratory bench

Tubing inside the fume hood featuring open quick-turn couplings with shut off valves to connect to the condensers

For each bench, a Heidolph HEI-CHILL 600 is used and all units were purchased with WatSEF funds.

These chillers replace the use of running tap water into condensers for cooling. We also minimize the risk of floods since these is limited liquid in the chillers versus continual source from a faucet. For small scale applications, a water pump (like ones used in aquariums) can be used to circulate water from a bucket with a bit of ice. Very cost effective solution!

The chiller is filled with a 50% water, 50% ethylene glycol mix and the temperature can be adjusted. For condenser use, we chose 11 °C to be close to ground water temperature. With colder temperatures, we found that the tubing would get a large amount of condensation on the outside. We are now looking at tryin 15 °C to further decrease this issue but it is pretty minimal.

Lines of tubing were installed and branched to provide two connections per fume hood. Installation is fairly straightforward and was completed by Science Facilities. Condensers are connected via quick-turn couplings with shut offs. The system must remain looped to avoid over-pressure and leaks.

For the system, we ordered parts mostly from McMaster-Carr:

-

Plastic Quick-Turn Tube Coupling with Shut-Off for Air and Water, Plug, for 1/4" Barbed Tube ID (part ID 9198T13 and 9198T16)

-

Braided tubing?

-

Clear Masterkleer Soft PVC Plastic Tubing for Air and Water, 1/4" ID, 3/8" OD (part ID 5233K56) – tubing to condenser

-

Plastic Barbed Tube Fitting for Air and Water Tight-Seal, Elbow, for 1/4" Tube ID (part ID 5463K594)

-

Plastic Barbed Tube Fitting for Air and Water Tight-Seal, Straight Connector, 1/4" Tube ID (part ID 5463K578)

-

Plastic Barbed Tube Fitting for Air and Water Tight-Seal, Tee Connector, 1/4" Tube ID (part ID 5463K606)

-

Constant-Tension Spring Clamps for 7/16" OD Hose and Tube, Double Spring (part ID 5324K315)

For the connections to the condensers, we need to keep the system looped as much as possible to avoid over-pressure. We found that with a couple of "dead-ends", the connections end up popping off and creating a small flood. So we instruct student to keep connectors together at all times. This means that we lost the ability to test that students know water must flow from the bottom to the top of the condenser as the condensers are set up to always be connected this way.

A small issue we have had with the system was tubing touching the hot elements from the hot plate and melting through which creates a flood. Usually the students notice quickly and we have them plug the hole with their fingers. Usually the hole is created on the part of the tubing on the condenser and it can simply be disconnected and the tubing is replaced. If the hole is on the tubing coming out the fumehood, we need to turn off the chiller and cut the line to remove the damaged portion.

Rotary Evaporators

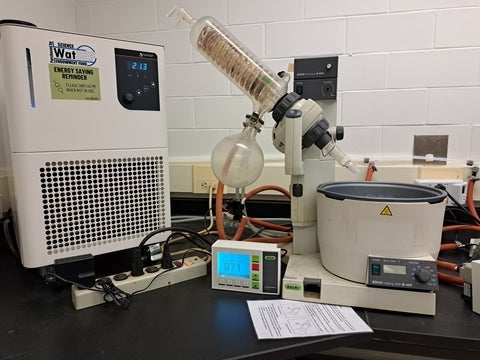

Buchi R-200 rotary evaporator connected to I-100 interface and Hei-CHILL 600 chiller. Vacuum provided by Vacuubrand MD 12C pump (not pictured)

Vacuum pump used for the vacuum network for the rotary evaporators. Six rotary evaporators are connected to one pump.

There have been rotary evaporators (also known as rotavaps) in the laboratory before my hire. The units themselves still are functional but some add-ons were purchased to ensure they would work with the new sustainable lab.

- Vacuum network: All six rotary evaporators are connected in series to a single pump from Vacuubrand (MD 12C NT +AK +EK model), purchased with funds from the Faculty of Science and designed along with the network at the benches. By having all rotavaps connected together, I was able to save funds since the model required for rotary evaporation is more expensive than the one used at the fume hoods for suction filtration.

- Chiller: One Hei-CHILL 600 is needed for two rotavaps and the units were purchased with WatSEF funds along with the units used for the condensers at the fumehoods.

- I-100 interface: Purchased in 2024 with funds from the Chemistry Program Activation Fund. These controllers allow to turn the rotavaps on and off and adjust the depth of the vacuum to follow the delta 20 rule for efficient evaporation. Before I had the controllers, I needed to put a flask on the rotavaps when not in use since they would take in a lot of air and decrease the overall vacuum due to the "in-line" connection of the rotavaps.

Since the rotary evaporator are close to the end of their life, we have thought of sustainable ways to upgrade them when the time comes:

- Broken condenser coils were replaced from surplus equipment or repaired by Science Technical services.

- New rotavap "bodies" compatible with the glassware (condenser coils, collection flasks) be purchased which limits the waste.

- We are connected with a Lab Exchange via the Green Labs program to donate any parts that could be useful to others!

Hot Plate with Heat-on Attachment

Heidolph hot plate with heat-on attachment. Inserts are available for 50 and 100 mL flasks and different heat-on attachments fit larger flasks.

Heidolph hot plates and heat-on attachments were purchased with laboratory budget before my hire. The heat-on attachments provide very efficient heat transfer and require only minimal sand that can be reused.

This eliminates the dangers associated with oil baths frequently used in research laboratories. Heating is also very quick which is useful for undergraduate laboratory classes limited to 3-hours sessions.