Nano particle production and characterisation is now one of the hot topics in science, engineering and industry. Perhaps surprisingly (given its ability to disrupt matter by rapidly removing many electrons from anything in its way) femtosecond laser pulses have recently been shown to be a highly promising tool in generating nano particles. In fact it is precisely this disruptive capability which is the quality which promotes the nano particle production. When femtosecond laser pulses interact either with a liquid or a solid they cause a the material to be rapidly reduced to ionised atomic and molecular fragments which can then self organise to form either nano scale surface features which dramatically modify the properties of a material or nano particles of varying sizes and properties. One of the nicest particles is a polyyne chain which consists of carbons bound to each other and capped at each end by a hydrogen atom. These chains have been found to have extraordinary properties such as strength beyond that of diamond (also made of carbon).

Usually polyynes are produced from graphite powder (soot) in a liquid heated by an electric discharge or high energy laser pulse. Recently it has been found that instead of this messy method it is possible to take a clean solvent solution and irradiate it with pulses from a femtosecond laser. The result is a solution containing polyynes and other fragments of the initial solvent. One of the ways that the femtosecond laser is able to process the liquid effectively is by generating a bright filament, in which nonlinear interactions between the laser field and the liquid increase the length of the focus by orders of magnitude.

Hydrogen-capped and methyl-capped carbon chains (polyynes) have been generated by intense femtosecond laser irradiation of pure liquid toluene. UV-Vis and Raman spectroscopy were used to confirm the presence of polyynes in the irradiated samples, and high performance liquid chromatography (HPLC) was used to separate polyynes.

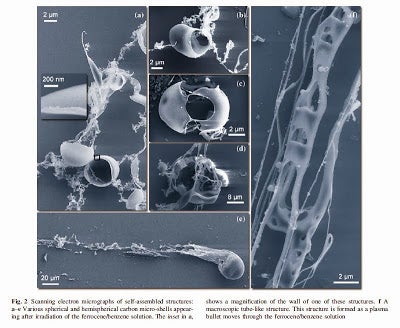

Nanoparticles are generated in a liquid. Using an ultrafast filament, many structures can be identified.

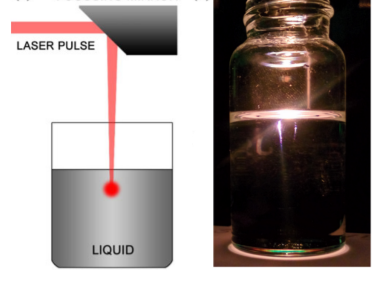

A schematic of the experimental setup and an image of the laser-liquid interaction during irradiation.