Although traditional manufacturing has experienced a decline in North America, industry, government, and academic institutions are working together to foster a shift toward more competitive manufacturing through innovation and technology.

Researchers at the Waterloo Centre for Automotive Research (WatCAR) interested in vehicle assembly are pursuing design and development processes onscreen, in a virtual environment, with the objective of achieving more rapid and economical product development. This is playing a growing role in the development and deployment of technologies such as fractal analysis of vehicle component structures and vehicle-to-vehicle communication. WatCAR is creating cars with increased efficiency and stability that are more crash-proof and recyclable.

Impacting the manufacturing process

Advanced manufacturing improvement is a continuous pursuit in the automotive sector, with all segments of the supply chain striving to realize efficiencies while reducing costs. In particular, flexible manufacturing systems and reduced-size devices are paramount for assemblers. Research at WatCAR is leading to fewer and more intelligent manufactured components, improved assembly line designs that reduce repetitive strain injury and improve productivity, parts-movement within a just-in-time logistics integration system for improved efficiency, as well as deeper integration of sensors to expand functionality of on-board devices. Researchers are also building sophisticated models that map the impact of the manufacturing process on resulting material properties and ultimately product performance. These models then feed into process optimization and control.

With strength in device development at the nanoscale in several departments in the Faculty of Engineering, research in manufacturing and devices at the University of Waterloo will continue to be robust and innovative. In addition, a broad spectrum of new technologies is being developed at the Waterloo Institute for Nanotechnology (WIN) including transparent, flexible display screens, nano-enabled biodiagnostic medical devices, and nanocellulose and nanofibre modified plastics. Quantum computing and nanotechnology have opened new doors for novel research in nanobio-based quantum devices, furthering investigations that have spawned devices such as lab-on-chip, where several lab functions can be performed on a relatively tiny device. New materials such as graphene and carbon nanotubes are driving innovations such as printed electronics in traditional industries. Researchers are also investigating nanowire materials such as ZnO and hybrid nanowire/thin film structures for solar cell and sensor applications.

Revolutionizing the future of manufacturing

As an institution that seizes opportunities to lead in new and emerging areas, Waterloo is leading the way to a renewed future for manufacturing and devices that will revolutionize not only the auto industry but other sectors as well that are heavily dependent on manufacturing. The improvements in manufacturing emanating from this research will be manifest in virtually all consumer products, from those that have only recently begun to make our lives easier to those that are now taken for granted.

Waterloo has long been recognized for its cutting-edge research in radio frequency (RF) technologies, including RF Micro-Electro-Mechanical Systems (MEMS), miniature RFID, wireless intelligent systems, filters and multiplexers, superconductivity, novel materials,computer-aided circuit diagnosis, simulation, and modelling. New circuits and diagnosis will be required for systems that experience mechanical strain while operating, including integration of disparate materials and flexible platforms for both enhanced functionality and performance.

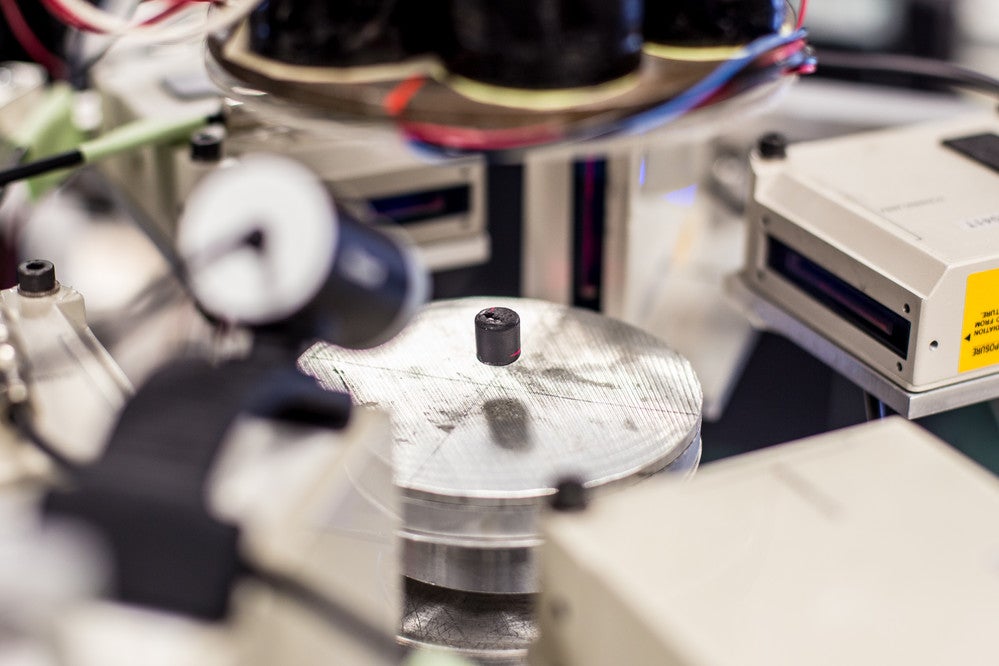

Researchers at Waterloo have their eyes on another enabling technology — additive manufacturing, also known as 3-D printing. The engineering research that makes this mass customization and rapid prototyping possible includes bio-fabrication, opto-mechanicalsensor development, and laser-assisted microdeposition.

Fundamental research is also underway in welding and joining with emphasis on micro-welding, nanojoining, impact welding, and brazing.