Description and uses

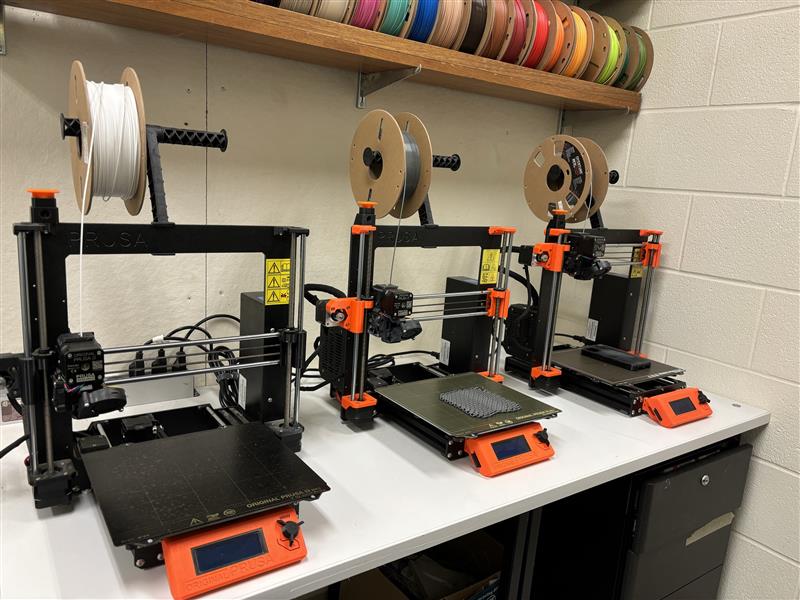

The Prusa i3 MK3S+ is a highly regarded 3D printer known for its exceptional reliability, precision, and ease of use. Developed by Prusa Research, this iteration builds on the success of its predecessor with enhanced features that make it one of the top choices for both hobbyists and professionals. It boasts a sturdy frame, automatic bed leveling, filament sensor, power recovery, and improved print quality. The MK3S+ is also praised for its extensive community support and open-source design, allowing users to modify and improve the printer to suit their needs. Whether you're new to 3D printing or an experienced maker, the MK3S+ offers a seamless and rewarding experience.

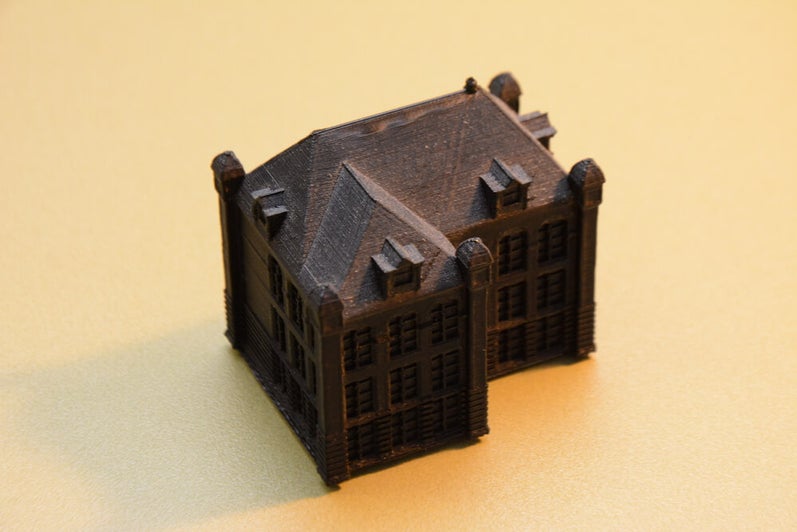

3D printer is an additive layer manufacturing technology; specifically, fused deposition modeling (FDM). As the print head moves, the ABS filament feeds through the heated extruder and deposits on the platform in the desired shape for the layer. When the print for one layer is complete, the platform will lower slightly (depending on the resolution) to the next layer and starts printing on the new layer. This process repeats until the model is complete.

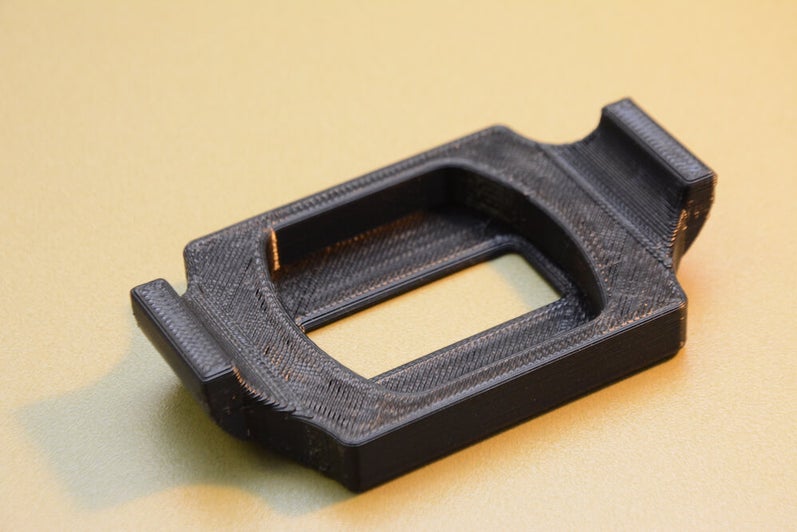

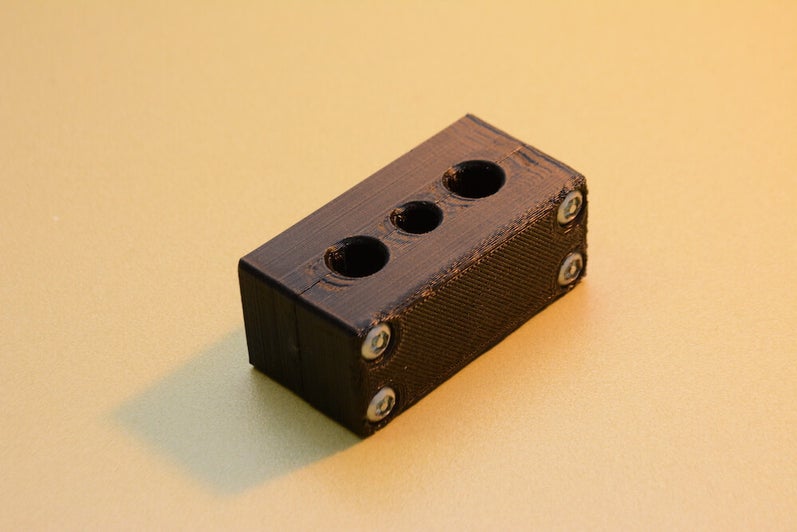

PrusaSlicer software is used to run the 3D printer. Designs are usually in STereoLithography (.stl) file type and created using 3D computer-aided design (CAD) software, such as Autodesk 123D, Inventor, and SketchUp. See examples of 3D designs on Thingiverse or consult Dan Beaver (Workshop Coordinator) about the capabilities and constraints of the 3D printer.

Further considerations

- Prior to using the 3D printer, locate the nearest fire extinguisher in case it is needed in an emergency.

- An operator must be present by the 3D printer and monitoring it at all times due to fire risk.

- Before printing the final model, it is best practice to print a test model with a very low infill percentage and a highly-efficient infill structure like the diamond to ensure the specifications are met.

- If the estimated build time is too long and the structural integrity is not of concern, then reduce the infill percentage and use the diamond infill structure to decrease the build material and time.