Metal Working Equipment

Universal Milling Machines

These holdvarious types of cutting tools while you move the table that has your part secured to it, across the tool to remove material in straight lines. Common uses are to make squareor rectangular projects, and accurate hole patterns.

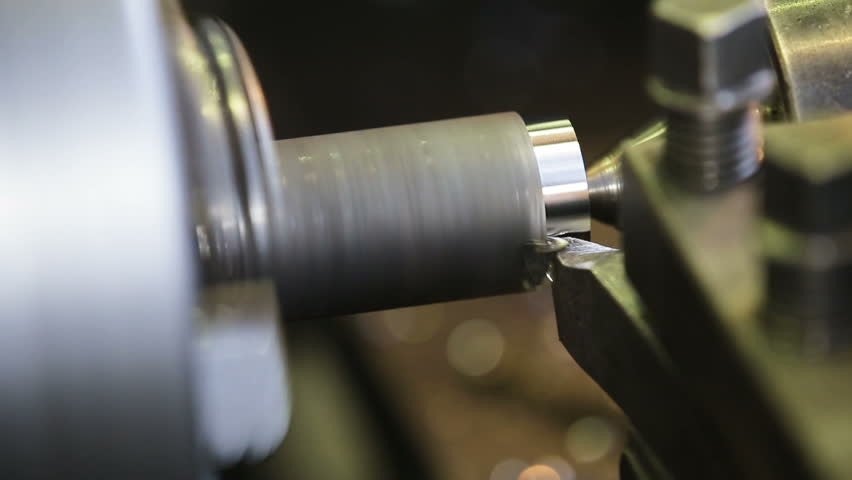

Engine Lathes

These spin your work piece as you run a cutting tool across it, so you can take equal cuts on all sides of your piece. They are used to create cylindrical or conical projects.

Drill presses

These are mounted drills to improve accuracy and efficiency of drilling holes into projects. They are used to drill various sized holes.

Vertical Bandsaws

These have a continuous blade that only travels in one direction, so the blade is always cutting as you push your part through into the blade.They are used to make rough straight or curved cuts.

Belt and Disk Sander

This rapidly moves abrasive pads or belts to grind away various types of materials. It is used to remove small amounts of material.

Horizontal Bandsaw

This has a continuous blade that travels in one direction and, by using hydraulics, the blade is lowered onto your part to make more accurate cuts. It is used to make rough straight or angled cuts.

Squaring Shear

This is a long straight blade that is brought down to cut your material when you step on the foot peddle. Is used to made straight cuts in sheet metal.

Pan Brake

This will hold sheet metal, so you can bend it to a desired degree when you lift the handle of the brake. Is used to get a nice bend in sheet metal.

Hole Punches

These use a matching set of punches and dies to create different types and sizes of holes when they pierce through sheet metal. It is used to make putting holes into sheet metal easier.

Corner Notcher

This is a blade with a right angle that is brought down to cut your material when you pull the lever. It is used to cut right angle chunks out of sheet metal.

Wood Working Equipment

Thickness Planer

This can take layers off all sizes and shapes of wood. As your material is fed into the machine, it cuts off the top layer. It is used to reduce the thickness of wood and flatten out the surface it is cutting.

Tabletop Router

This has various shapes of cutting bits that can either plunge into wood projects or cut material off edges. Its common uses are to cut groves and shape the edges of projects.

Miter Saw

This has a circular blade that is brought down to chop through your material. It is commonly used to make straight or angled cuts on planks of wood.

Track Saw

This is a handheld saw that has a small circular blade and the handle fits into a track, so it can travel straight. It is used to make long straight cuts in different sizes of wood.

Scroll Saw

This is mounted on a stand and uses a small straight blade that travels up and down rapidly. A common use is to cut tight curves.