Introduction about Mg alloys

AZ-based Mg alloys are produced by adding aluminum (Al) and zinc (Zn) to pure Mg. Appropriate amounts of additives may improve the strength, castability, workability, corrosion resistance and weldability of these alloys. In addition, AZ based alloys have high formability and weldability and ZK-based Mg alloys, which are produced by adding zinc (Zn) and zirconium (Zr) to Mg, have a higher hot- workability than other materials. AM series alloys, which are produced by aluminium (Al) and manganese (Mn) to Mg, have good combination of strength, ductility, energy absorption properties and castability. Multiaxial fatigue design analysis on automotive Mg-alloys will be conducted on two extruded alloys: AZ31B and AM30.

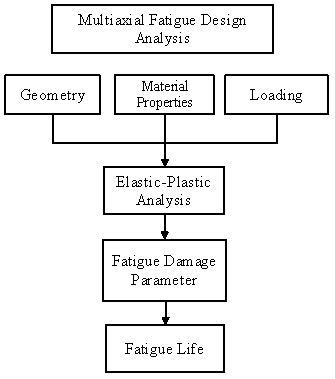

Introduction about Mg alloys multiaxial fatigue design analysis

A multiaxial fatigue design model consists of three parts: material characterization parameters, multiaxial elastic-plastic stress-strain analysis and a multiaxial fatigue damage parameter. The model requires analytical, numerical and experimental techniques.

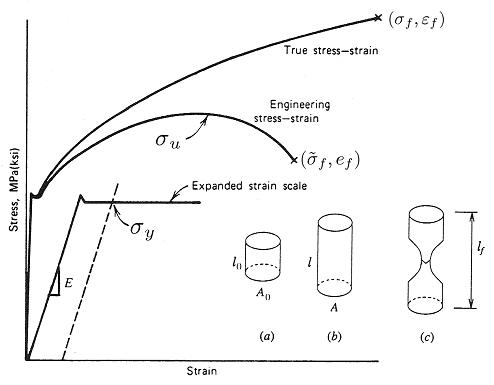

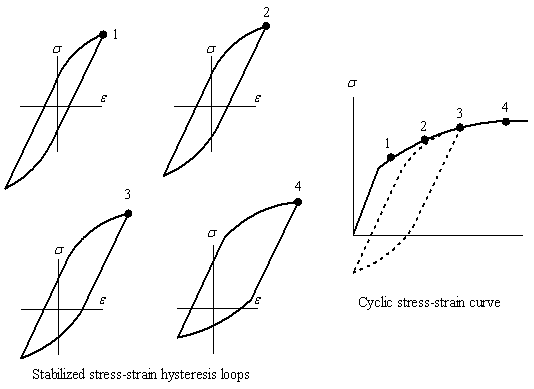

Material characterization

Material characterization includes both monotonic and fatigue behaviours. The relation between a fatigue damage parameter and fatigue life usually appears in terms of material constants. These constants are obtained by performing both monotonic and cyclic tests. Hardening or softening behaviour in monotonic or cyclic loading needs to be known. Moreover, some materials experience additional hardening due to nonproportional multiaxial loading. These phenomena can be investigated by conducting tests on smooth laboratory specimens. Here, two loading modes are considered: tensile and torsional. Monotonic stress-strain curves will be obtained for both types of loadings and the related material properties will be determined. Cyclic tests will also be performed. Tension and torsion strain-controlled fatigue tests allow the determination of cyclic stress-strain and fatigue life curves. Combined tension-torsion strain-controlled fatigue tests will be used to examine the effect of multiaxialty on fatigue life.

Stephens et al., 2001 “ Metal fatigue in engineering” 2nd edn, John Wiley and Sons, Inc., New York.

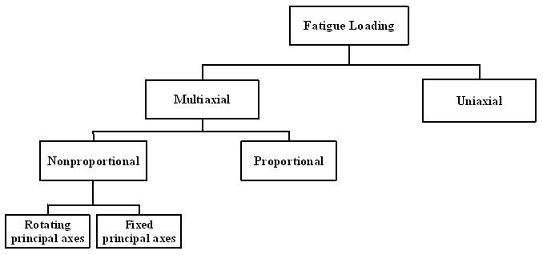

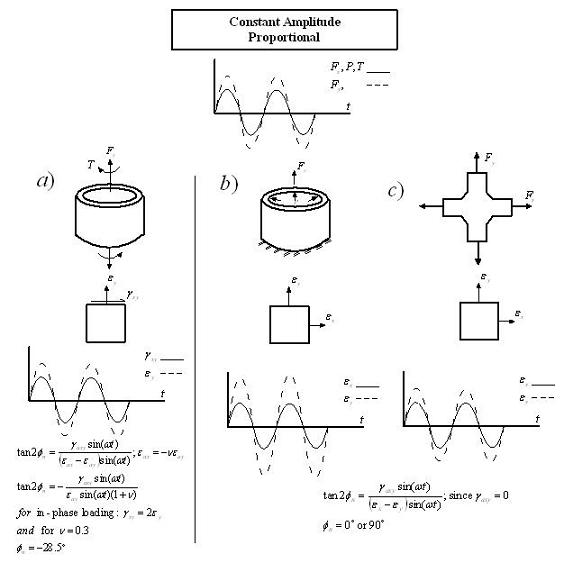

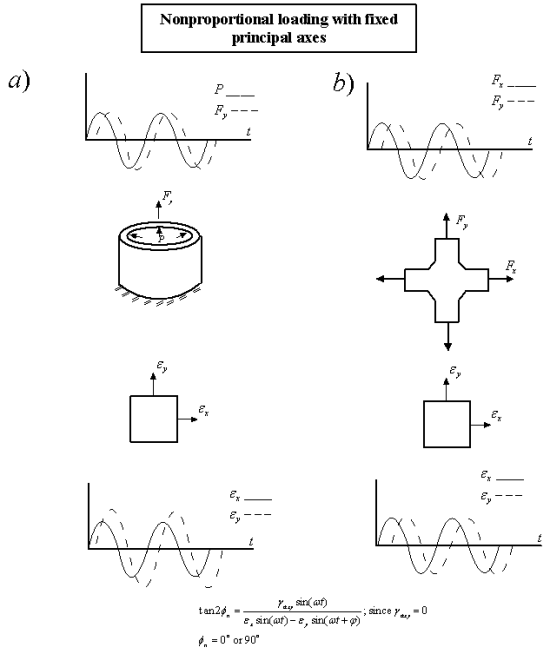

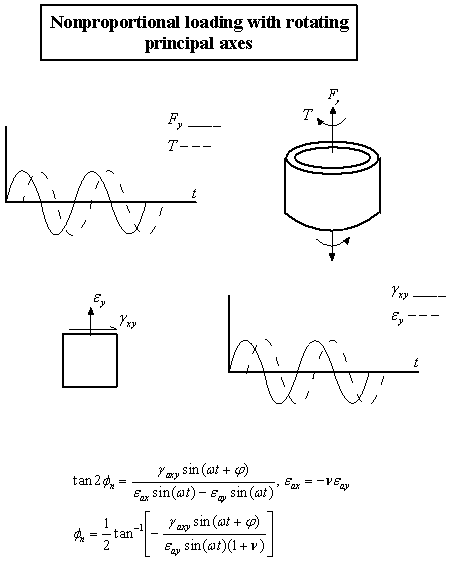

Multiaxial fatigue loading

Multiaxial fatigue loading is classified into “proportional” and “nonproportional” loading. Nonproportional loading is divided into rotating and fixed principal axes loading. These loading are illustrated in the next figures. The degree of multiaxialty will affect the fatigue life and 90° out-of-phase multiaxial loading is the most damaging. A thin tube subjected to cyclic axial and torsional loading with a phase differences a nonproportional loading case with rotating principal axes. This is the most general and complicated situation.

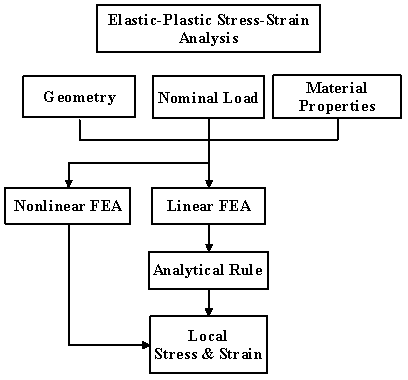

Elastic-plastic stress-strain analysis

Elastic-plastic stress-strain analysis is required to calculate stresses and/or strains at the expected failure sites, i.e., notches. A rule that relates nominal to local stresses is needed for notches under multiaxial stresses. For a complex geometry that is subjected to a multiaxial fatigue loading, two approaches can be used. Either using nonlinear finite element analysis or combined linear finite element and analytical analyses.

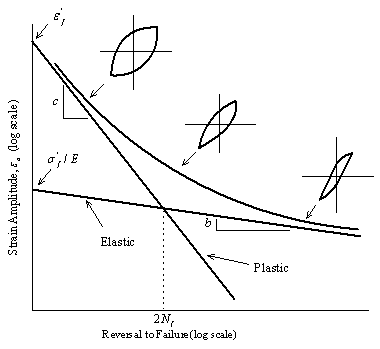

Multiaxial fatigue damage parameters

Multiaxial fatigue damage parameters are usually formulated using basic constituents such as stress and/or strain as well as material-related quantities. These parameters are related in different ways to the fatigue life and reflect the real physical damage that occurs in the material. There are three approached for multiaxial fatigue damage calculation: stress, strain or energy approaches. If these quantities are calculated at a selected plane then this is called “critical plane approach”. Critical plane criteria are able to predict both fatigue life and the orientation of the failure plan. Strain and energy approaches are suitable for fatigue design analysis because of their localized nature. Therefore, these two approaches will be considered in this study as well as critical plane approaches.

Model verification

Testing Capabilities

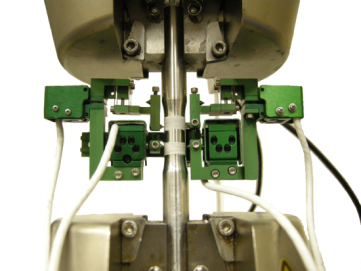

- 2620-601 axial extensometer with a gage length and range of 12.5mm and +/- 5.0mm, (for monotonic tests)

- 2620-603 axial extensometer with a gage length and range of 10mm and +/- 1.0mm, (for fatigue tests)

An Epsilon 3550 axial-torsional extensometer will be used for axial-torsional strain measurements. This extensometer has a torsional shear strain angle, an axial gage and an axial strain of +/- 4degress, 10mm and +/- 5.0, respectively.

Fatigue and Stress Analysis Laboratory, University of Waterloo

Fatigue and Stress Analysis Laboratory, University of Waterloo

Fatigue and Stress Analysis Laboratory, University of Waterloo

References

-

Albinmousa, J, Jahed, H, Lambert S, “Cyclic Behaviour of Wrought Magnesium Alloy under Multiaxial Loading,” International Journal of Fatigue, 33, (11), (2011), 1403-1416;

-

Albinmousa, J, Jahed, H, Lambert S, “Cyclic Axial and Cyclic Torsional Behaviour of Extruded AZ31B Magnesium Alloy,” International Journal of Fatigue, 33, (8), (2011), 1127-1139;

-

Albinmousa, J, Jahed, H, and Lambert, S. (2011), “Multiaxial Fatigue Life Prediction of AZ31B Extrusion”, The 23rd Canadian Congress of Applied Mechanics, June 5-9th, Vancouver, BC, Canada

- Albinmousa J, Jahed H, Lambert S, " An energy-based fatigue model for wrought magnesium alloy under multiaxial load ", 9th International conference on multiaxial fatigue and fracture, ICMFF9, Parma, Italy, June 2010

- Albinmousa J, Jahed H, Lambert S, Begum S, Chen D, Duan Q, Luo T, Yang Y, Zhang Z, Horstemeyer MF, Jordon J B, Pascu A, Luo AA, Osborne R, Su X, Zhang L, " Monotonic and Fatigue Behavior of Magnesium Extrusion Alloy AM30: An International Benchmark Test in the Magnesium Front End Research and Development Project ", SAE2010 World Congress, Detroit, US, April 2010

- TMS 2010 Annual Meeting & Exhibition, “Monotonic and Multiaxial Cyclic Behavior of the Extruded AZ31B Magnesium Alloy”, Jafar Albinmousa, Hamid Jahed, Steve Lambert.

- SAE 2010 World Congress, “Monotonic and Fatigue Behavior of Magnesium Extrusion Alloy AM30: An International Benchmark Test in the "Magnesium Front End Research and Development Project”, J. Albinmousa, H. Jahed, S. Lambert, S. Begum, D. Chen Q. Duan, T. Luo, Y. Yang, Z. Zhang, M.F. Horstemeyer, J. B. Jordon, A. Pascu A.A. Luo, R. Osborne, X. Su and L. Zhang.

- The Ninth International Conference on Multiaxial Fatigue & Fracture (ICMFF9) 2010, “An Energy-Based Fatigue Model for Wrought Magnesium Alloy under Multi-axial Load”, Jafar Albinmousa, Hamid Jahed, Steve Lambert.