Education and Positions:

- Post-Doctoral Fellowship, Mechanical and Mechatronics Engineering, University of Waterloo, 2020-Present

- PhD, Mechanical and Mechatronics Engineering, University of Waterloo, 2020

- BSc, Vehicle Engineering (Automobile), Tongji University, 2013

Projects:

AI-involved Ball Grade Selection System (2020.7 - 2021.2): Project lead

A project to help select suitable ball size in a tube and shaft assembly. A synthetic model comprised of analytical model derived from physics and ANN model trained from experimental data was established. A program with user interface based on TensorFlow library was coded with python. The model has been deployed to the production line.

- Data analysis with Python

- TensorFlow powered machine learning

- UI development with Python

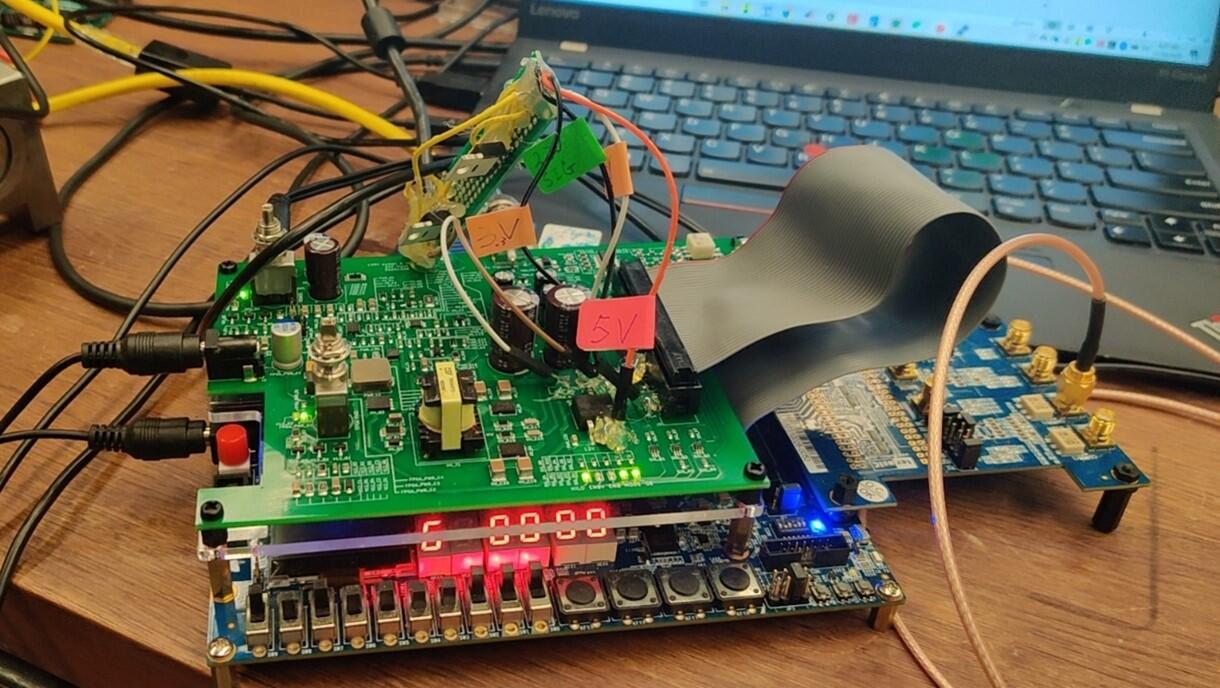

FPGA-based Ultrasonic Non-destructive Testing (NDT) System (2018 - now): Project lead, PhD thesis related

A project to develop a portable low-cost ultrasonic system. Customized PCBs were developed to drive ultrasonic probes. DE10-Standard board was used as the core of the system. A working prototype has been made. Eventual goal of the project is to develop an online data screener and analyzer with AI algorithm. The development is still undergoing.

- PCB design with KiCAD

- Hand-soldering techniques

- Intel FPGA development with Intel Quartus Prime (Qsys and verilog)

- C++ programming for ARM system

Laser Distance Sensor Integration (2019.7- 2019.9): Project lead

A project to develop an interface for a laser distance sensor to be integrated into the automation system for optical gauge.

- Circuit design

- Arduino programming

Samosa Making Machine (2019.3 ~ 2019.8): Team member

A project to investigate the possibility of using machine automations to make samosas with authentic wrapping techniques.

- Mechanical design

- how to make a nice samosa!

Development of Ultrasonic Tactile Sensor (2015 - 2018): PhD thesis related

A project to develop a non-invasive tactile sensor which operates at ultrasonic frequency. The project evolved from a project to develop ultrasonic surface treatment device. The development included analytical derivations, numerical simulations, and manufacturing with lathe and mill. The developed sensor can estimate elastic modulus of soft solid material without causing damage.

- Analytical modeling with MATLAB

- Numerical simulation with COMSOL

- LabVIEW programming for signal acquisition

- Machining with lathe and mill

Wireless Anglometer Development (2017.10 - 2018.10): Project lead

A project to design and develop a digital sensor that was able to measure the angle of rotation on a shaft. The sensor features data acquisition, live digital display, warning speaker, and wireless communication. The sensor has been deployed in the field.

- PCB design with KiCAD

- Hand soldered PCB prototype

- Arduino programming

- VBA programming for the data receiver through serial port in EXCEL

- Mechanical design

Automated Powder Dispensing System for Swimming Pools (2016.5 - 2016.12): Project supervisor

A project to design a prototype for the powder dispensing system which dispenses powder (e.g., chlorine) for pool maintenance at a controlled rate.

- Arduino programming with C++

- DC motor control

- Mechanical design

Atomic Force Microscope (AFM) Experiments (2014 - 2015): Technician

Various projects involving the operation of PARK System AFM. The tasks were mainly performing nano-scale measurements on live/dead cells.

- AFM operations

Automated XY stage and temperature sensor for Atomic Force Microscope (AFM) (2014.9 - 2014.10): Project lead

A project to add customized features to the AFM in the lab: 1. Convert the XY stage in AFM from manual to motor control; 2. Include an online temperature feedback for the liquid in the petri dish.

- Labview programming

- Stepper motor control

- Thermocouple-based sensor design

Advanced Sound and Vibration Tests on Automobile (2013.9 - 2014.9): Technician

Various experiments in different projects relating to automotive industrial R&D. Most of the projects were done in the anechoic room with a silent drum test bench in the automotive lab of Tongji University.

- Live and post data analysis with LMS Test.Lab

- Modal analysis

- Sensor (vibrometer and microphone) placement and calibrations

- Signal processing with MATLAB

Noise Equalizer Studies in Automobile (2013): Bachelor thesis related

A project aimed to evaluate influences on driver’s attention from interior noise of an automobile. Based on the evaluation, a prototype of an active noise cancelling device was developed. Machine learning technique based on Artificial Neural Network (ANN) was employed to perform qualitative noise evaluation. An online evaluation system with MATLAB and LabVIEW was established.

- Acoustic experiments with artificial head (HEAD acoustics HMS III) recordings

- LabVIEW and MATLAB integrated signal processing and analysis

- Artificial Neural Network (ANN) with MATLAB

- Close-loop control system design

Camera Guided Intelligent Car Development (2012): Team member

A project to develop an intelligent car powered by Freescale microprocessor. A limited performance CCD camera was used as guidance for the car. The programming was challenging due to the limitation on the processor power, memory size, and camera. On-board processing aimed to recognize turns, ramps, cross-roads, etc. Strategies were developed to finish laps as fast as possible.

- C/C++ programming for microchip controller

- PCB design with Altium Designer

- Hand soldered PCB

- Mechanical design and calibrations

- DC motor control

- Computer vision and pattern recognitions