|

Figure: Automotive coating process at one of the paint booths |

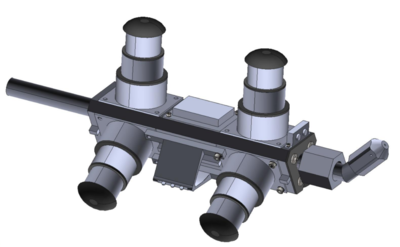

Title: Paint Exhaust Filtration Device [confidential] Objective: To investigate the automotive coating process at TMMC's paint booth and conceptualize design refinements to improve the filtration efficiency. I used SolidWorks and Ansys Fluent, along with post-processing scripts, to estimate the air flow patterns and applied my advanced design methods knowledge to conceptualize and propose an easy-to-implement, cost-effective design solution. The future cost benefit of this design project is estimated to be upwards of $500K per year in the form of Operation and Maintenance cost of the filtration unit. Design methodologies used: Process flow diagrams, requirements analysis, functional analysis, Morphological analysis, Pugh's decision matrix, Method 635, DELPHI, TRIZ, Design-for-safety, DFM/A. |

|

|

Co-op at Ansys |

|

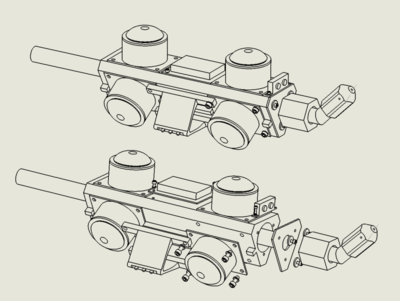

Figures: Original design space (left), CAD rendering of the final design (right)

|

Title: Glass Carving Assistive Device Objective: To design a device that would assist in carving operations, while meeting the client requirements. |

|

|

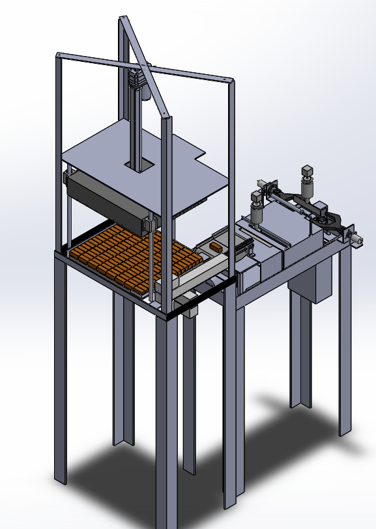

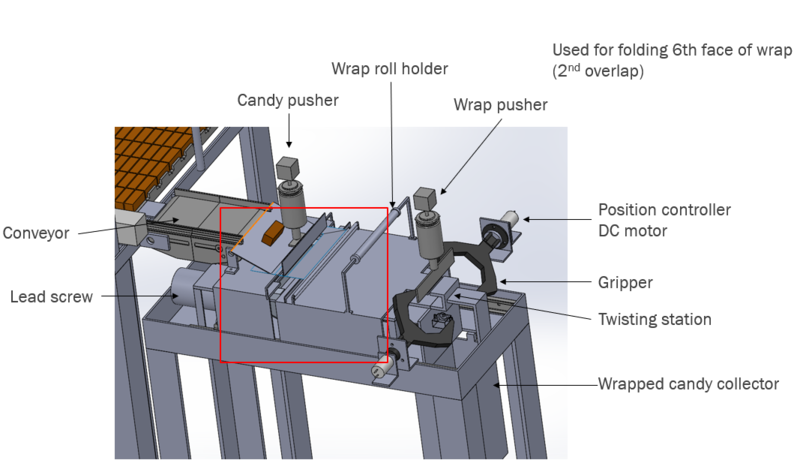

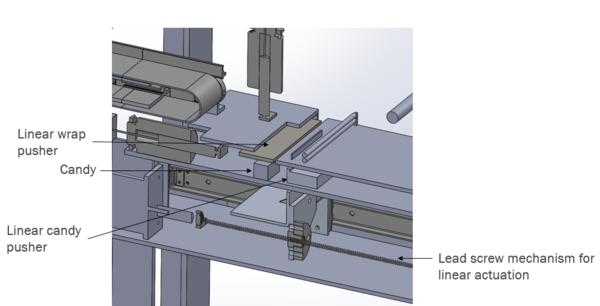

Title: Candy Wrapping Device Objective: To design an automated candy wrapping machine that would increase the throughput. The final design solution automated the workflow and increased the throughtput by 300%. |

|

|

Title: Robotic Arm Gripper Design |

|

|

Title: Sewer Cleaning Bot Objective: To design an automatic device that can unclog sewer blockages without direct human contact with sewage wastes. |

|

|

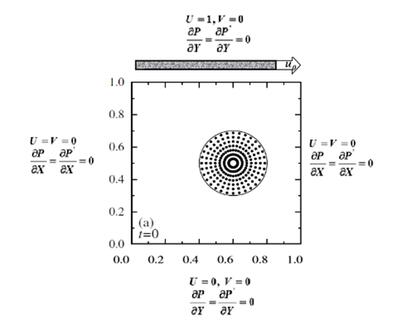

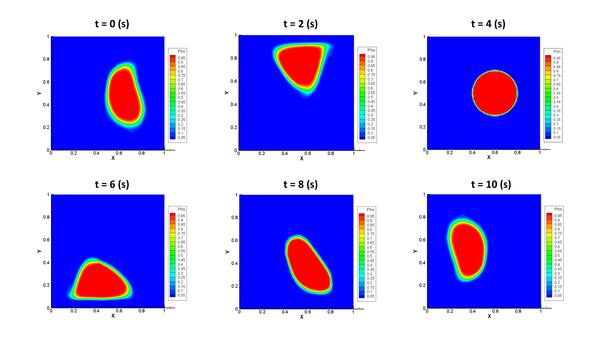

Undergraduate Thesis Title: Fluid-structure interaction study in an oscillating lid driven cavity |

University of Waterloo

University of Waterloo

43.471468

-80.544205

200 University Avenue West

Waterloo,

ON,

Canada

N2L 3G1