Background information

Micro-welding is a key fabrication process utilized in the manufacture of miniature devices, including implantable medical devices and MEMs. Commonly implemented welding processes include resistance micro-welding (RMW), laser micro-welding (LMW) and Micro-arc welding. It is critical to understand the effects of welding processes on the structure and properties of the material before implementing joints in sensitive applications. Hence, detailed microstructural characterization and performance evaluations are conducted at the Centre for Advanced Materials Joining (CAMJ). Research in this area will enable design engineers to reliably integrate and take advantage of new smart materials (i.e. Nitinol).

Objectives

- Investigate and characterize the influence of micro-welding processes on the weld microstructure

- Evaluate the functional material properties of the weld metal

- Conduct in-situ process monitoring

- Enhance process parameters to attain optimal weld performance

Equipment

- Unitek 500 series spot welder

- Miyachi Unitek series 300 spot welder

- THIN-LINE series 80 spot welder

- Micro-plasma arc welder

- Miyachi LW-50A low power laser

Pictures/figures

Figure 1) Dissimilar crossed wire joint of Pt/Ir to stainless steel using RMW (left) and LMW (right) processes

Figure 2) Optical micrograph of cross welded 316LVM at 1.6kW peak power

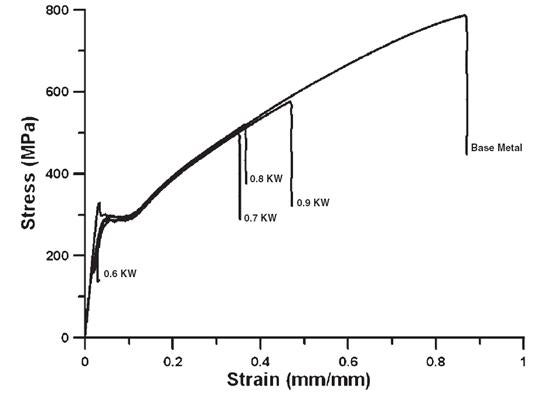

Figure 3) Representative tensile curves for LMW Nitinol with varying peak power input at 10 pulse per second frequency