June 23rd, 2022

Article published by The Waterloo Region District School Board

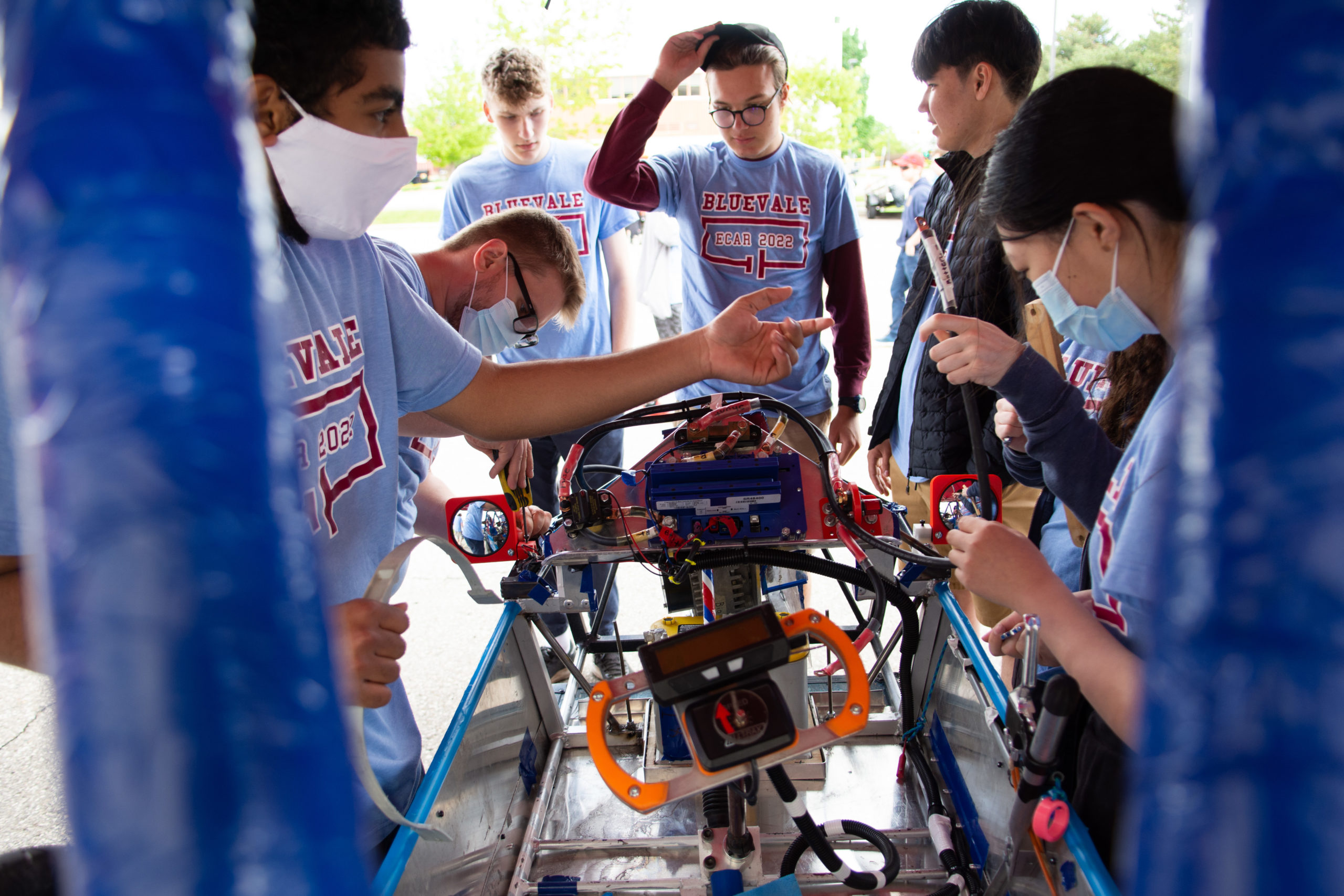

The sounds of cheering nearly drowned out the low purr of electric motors during the Waterloo High School Electric Vehicle (EV) Challenge at the University of Waterloo in May. The endurance racing event invites secondary students from across Ontario, including Bluevale Collegiate Institute (BCI), Eastwood Collegiate Institute (ECI), Laurel Heights Secondary School (LHSS) and Preston High School (PHS), to compete in electric vehicles of their own design and construction.

Students from BCI defended their title in both the 12 and 24 volt categories, while the team from LHSS took home third in the 24 volt race.

Emma Jenkins, a Grade 12 member of the BCI team, shared her feelings after the morning race.

“It’s just been a really great day,” said Jenkins. “I’m really happy with the results. We did really well. Kept up the 10-year record of Bluevale doing great, so I’m really happy.”

It wasn’t all about winning, though, as other students shared.

“We tried hard and we raced well, so I think we’re happy about it,” said Logan Eby, a Grade 12 member of the LHSS team. “It’s not necessarily too much about actually competing with the other schools, it’s mostly building the cars and having fun racing them.”

“We might’ve not won the race, but we got here,” said Dawa Tamang, a Grade 12 member of the ECI team.

Laila Elhossini, also a Grade 12 member of the BCI team, shared her excitement about being back at an event with students from other schools. She felt that their performance was the result of their hard work in the years and months leading up to the event.

“It’s awesome. It’s been so long since we’ve done anything in-person. This is the culmination of all our efforts, so it’s really satisfying,” said Elhossini.

Reflecting on his experience behind the wheel, Kenny Lin, a Grade 12 member of the LHSS team shared what it was like to be at the helm.

“Driving this thing is truly an awesome experience,” said Lin. “I love the sound of the electric engine. I love the rattling noise of the metal, and knowing that the speed and the control is all under your hands.”

“It feels great. I’d rather be doing this than sitting on the couch at home,” agreed Brandyn David, a Grade 11 member of the PHS team.

“The adrenaline from seeing all these magnificent cars and their designs is just wonderful,” said Ryan Persaud, a Grade 10 member of the ECI team.

Peter Teertstra, director of the Sedra Student Design Centre at University of Waterloo (UW) which hosts the race series, shared its origins. Starting with a series of events hosted at a secondary school in Orangeville, in 2012 UW took over the role of host, where the event has remained ever since. Teertstra shared his excitement to return to the in-person race, which had been paused during the pandemic.

“We’re really excited to be back and racing here at Waterloo,” said Teertstra. “It’s almost like a reunion, seeing everybody again.”

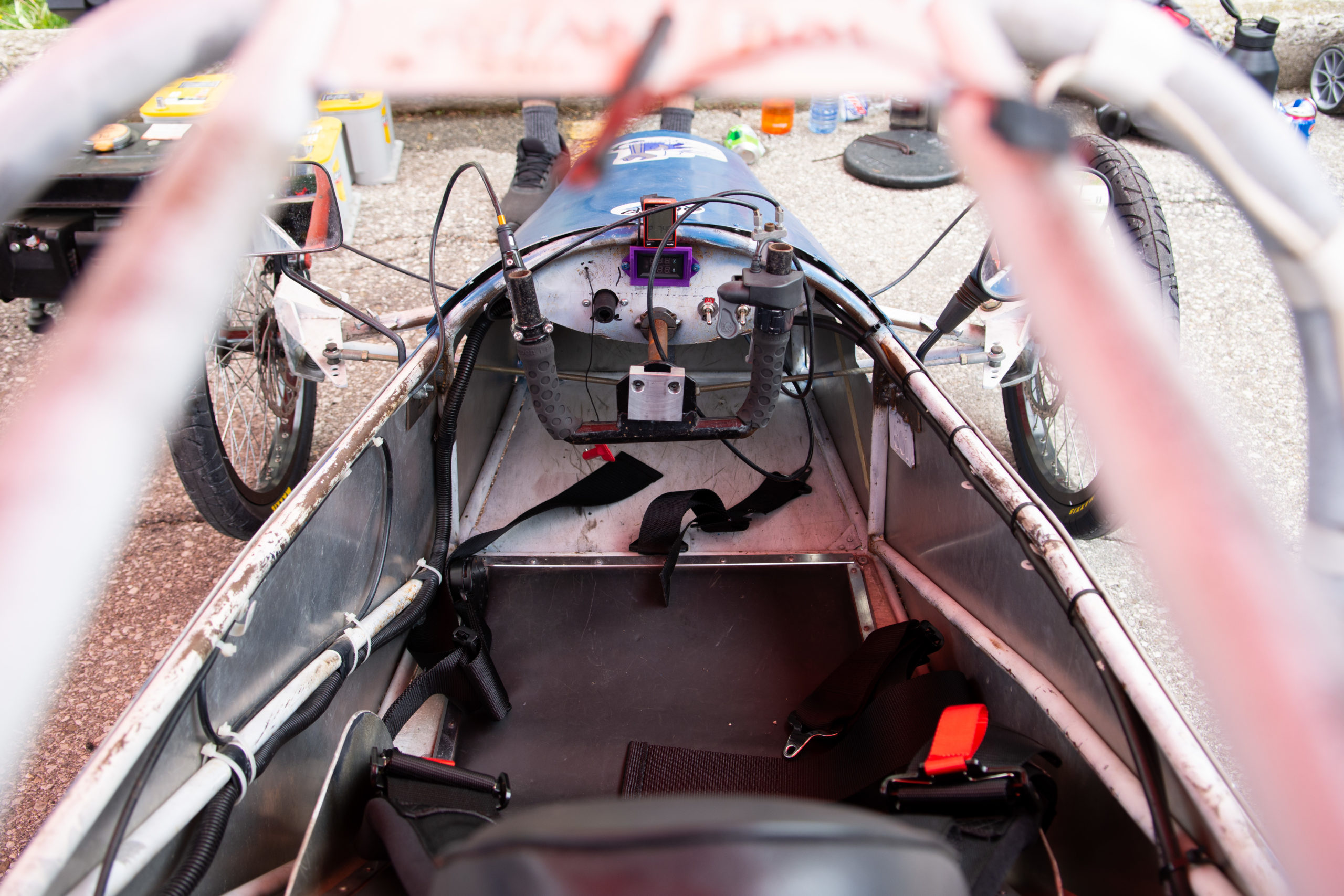

The nature of the challenge, asking teams to start from scratch as they build an electric car that runs on either one or two normal 12 volt car batteries, presents a multitude of learning opportunities for students, Teertstra explained. From collaboration and time management, to more specific skills like fabrication, welding or analyzing data.

“Just working on problems where the answer isn’t really clearly understood,” he said. “There are just so many different lessons that you learn as you go through a project like this.”

Jamie Cox is a tech design teacher at BCI, and a staff mentor of their team. He laid out the challenge that faces teams succinctly.

“The idea is to put a battery, or two batteries, in the racecar and to try and go as far as you can on that one charge,” said Cox.

He hopes that the experience will allow students to get a different perspective on green technologies.

“It’s racing…but it’s not racing in terms of going the fastest. It’s, ‘how do I take a finite amount of energy and actually use it in an effective way to go the furthest’,” said Cox.

In between the races, the students are hard at work, making sure the vehicles are in top shape for the harsh racing conditions. The low-slung vehicles are subjected to bumps and vibrations through the course of a race day, and need to be able to take the punishment.

“Maintenance on the cars is really critical,” said Cox. “The cars are just rattled.”

For students like Jenkins and Elhossini, this preparation is their favourite part.

“Working together and getting to work with my hands. I’m always better when I’m doing hands-on stuff, and I find it much more fun than theory,” said Jenkins. “Just being able to work with people and then seeing our efforts actually pay off.”

“Just getting my hands dirty, and being with like-minded people…and making cars. It’s awesome,” echoed Elhossini.

These are some of the benefits of being part of an electric car team, explained John Aguiar, an auto teacher at ECI and staff mentor of their team. From design, to engineering, to fabrication, to marketing and branding, there are an array of skills needed to create a strong team.

“It really incorporates a lot of various talents,” said Aguiar. There are “…a lot of different aspects that other students can get involved with that cater to their interests and skill set ”

Cox shared a recent example of this. Students on the BCI team created software that allows them to track their battery charge to help them achieve optimal performance.

“So we could actually see the battery power in real-time,” said Cox. “That’s a big advantage.”

This is how the students level up their teams year-to-year, explained Paul Brubacher, head of the Technology Department at PHS.

“You try to come back each time with a better, more improved vehicle,” said Brubacher. “It’s a learning process. It’s an excellent engineering experience for kids. To have to think, and fabricate.”

The students, too, share how meaningful this experiential learning has been for them. No matter where they are headed after graduation, the skills they’ll take with them will serve them well.

Jenkins, who plans to attend the biomedical engineering program at the University of Guelph, sees the applicability of what she’s learning on the electric car team.

“I’ll use all the skills here, between knowing how electrical circuits work and data for that,” she said.

Elhossini, too, plans to continue using the knowledge she learned as part of the team.

“Learning leadership, communication, organization – it’s been a great help learning all these skills,” said Elhossini. “I recently accepted my offer into mechatronics at UW. So, I hope to continue working on an EV team.”

These skills aren’t just applicable to those students headed to university. Bryan Clausi is a Grade 12 student on the LHSS team, and shared how this learning would help him.

“I’m going to be going to Conestoga next year for power systems engineering…this is right up my alley,” said Clausi.

Though some students will be graduating and moving on to their next challenge, many will be returning next year to take on the EV Challenge again. For them and their staff mentors, the focus now turns to making repairs and improvements.

Justin Shiaman, a Grade 10 member of the PHS team, explained that while this process can present challenges, figuring out how to overcome them creatively is the best part.

“Whenever something breaks or something goes wrong, trying to figure out how to fix it,” said Shiaman. “It kind of makes it fun.”

“Every year, we run into some crazy problem that nobody could have foresaw, and then you start to see the true design process going on where students really have to reach to make this work,” agreed Cox.

For any students or staff who are interested in putting together a team, Teertstra encourages them to reach out for guidance and support. He wants you to know you won’t regret it.

“Take the chance, take the risk, because it is so worth it.”