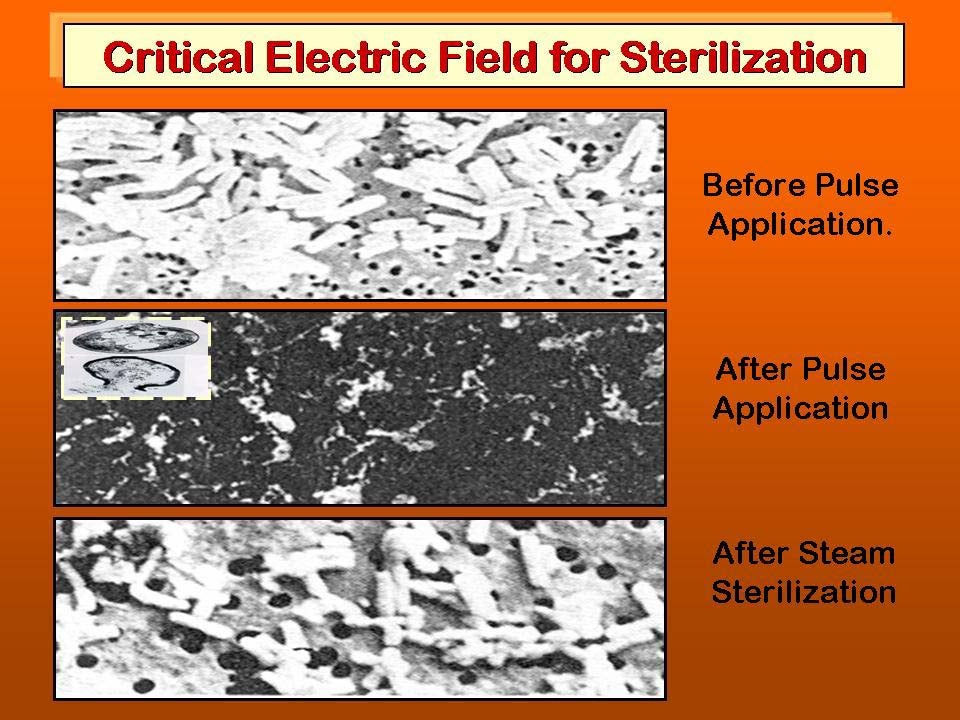

Pulsed electric field (PEF) for microbial inactivation

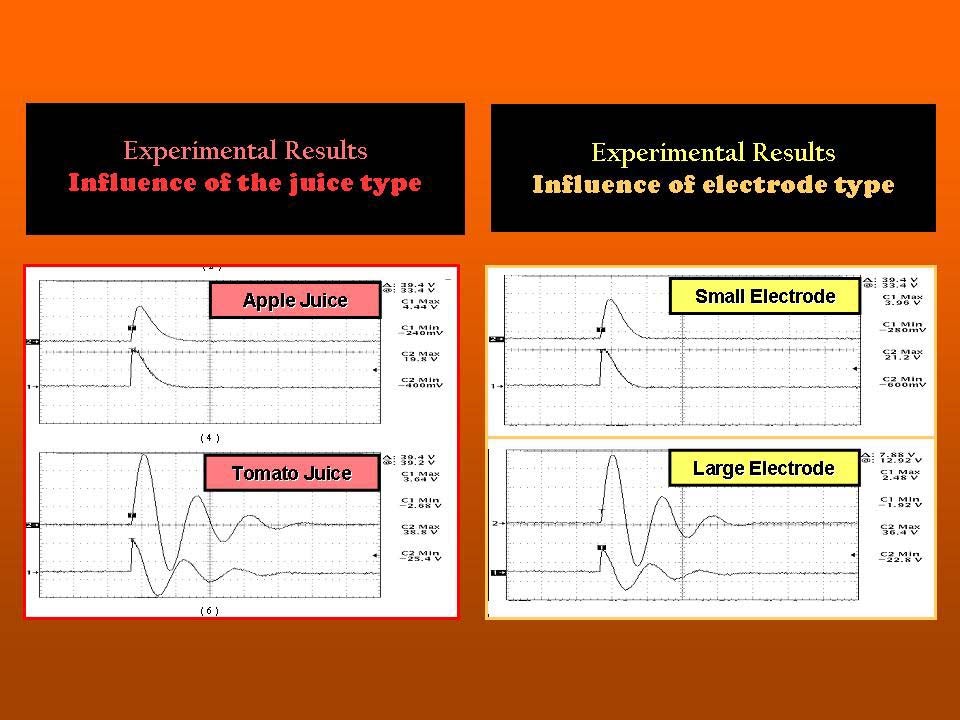

Microbial inactivation in liquid foods by PEF involves the application of pulses of high voltage to liquid food, so as to induce a substantially high electric field across the microbial cell membrane. We have been able to make significant contributions to the understanding of the kinetics of microbial inactivation and the theory of membrane breakdown. The synergetic effect of thermal and electrical fields has been demonstrated for the first time. Working with scientists from the Canadian Research Institute for Food Safety (CRIFS) at the University of Guelph, the team is developing prototype PEF Process technology to treat juices and dairy products. In addition, two major multinational processors of pure fruit juices, drinks and dairy products have been working together to implement the PEF technology. With support from these two companies, the use of a non-thermal pasteurization and sterilization of liquid foods using PEF will continue to contribute to the processing of liquid foods.

Electrostatics in process technology

A wide range of industries use high voltages and often encounter problems needing solutions that are very diverse. These include advanced electrostatic precipitators (ESP), Flue gas cleaning systems, and water purifying systems. A novel electron beam technology was developed for water treatment, as were special sources to generate superimposed pulses on DC voltage for ESP energization for ultra fine particle collection. High voltage applications in electrospinning to fabricate nanomaterials are the new directions taken in collaboration with the Food Science Research group at the University of Guelph.

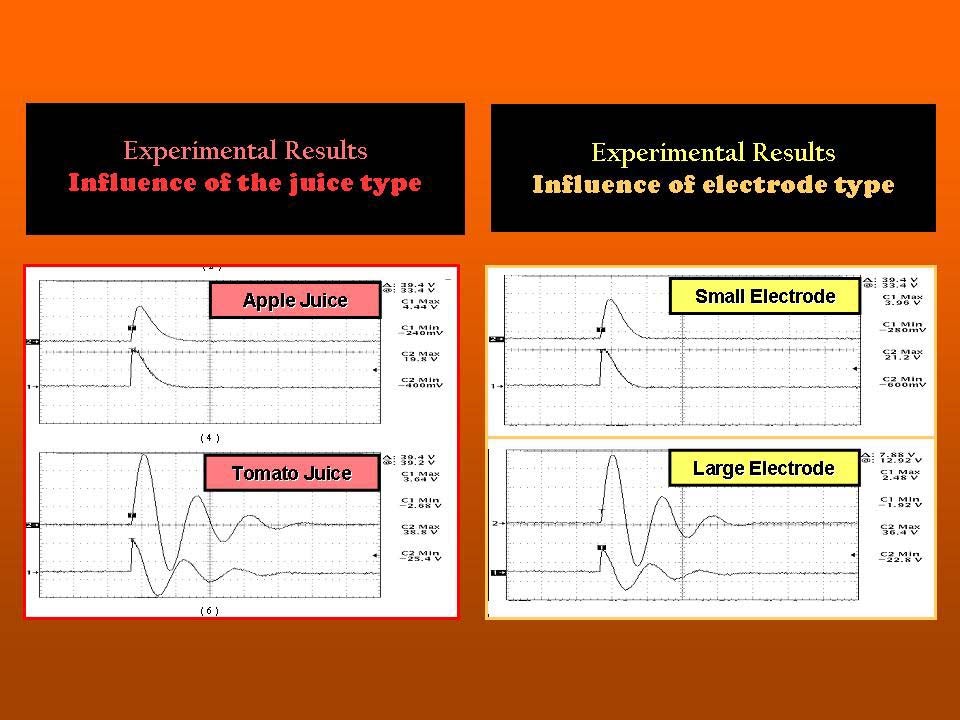

Treatment chambers for PEF pasteurization

The limitations to the industrial application of the PEF process are the generation of high electric fields and the design of treatment chambers that impart uniform exposure of foods to high electric fields, without increasing the temperature of the liquid food. Our work has provided solutions to these critical problems. We have developed a continuous PEF process system using the novel treatment chamber. The uniqueness of this chamber is that the electrode geometry has no edge effects; yet provides substantially high electric fields with smooth electrode surfaces. Providing laminar flow and uniform exposure of medium to sufficiently high electric fields has been accomplished.