Variable speed pulse width modulated (PWM) drives allow for precise speed control of induction motors as well as high power factor and fast response characteristics. However, due to the high switching frequencies and the high dV/dt there are increased dielectric stresses in the insulation system of the motor, leading to premature failure. Studies on the Inverter fed Medium and High Voltage Motor Insulation problems have been considered, in which all three areas of stator insulation are analyzed in depth.

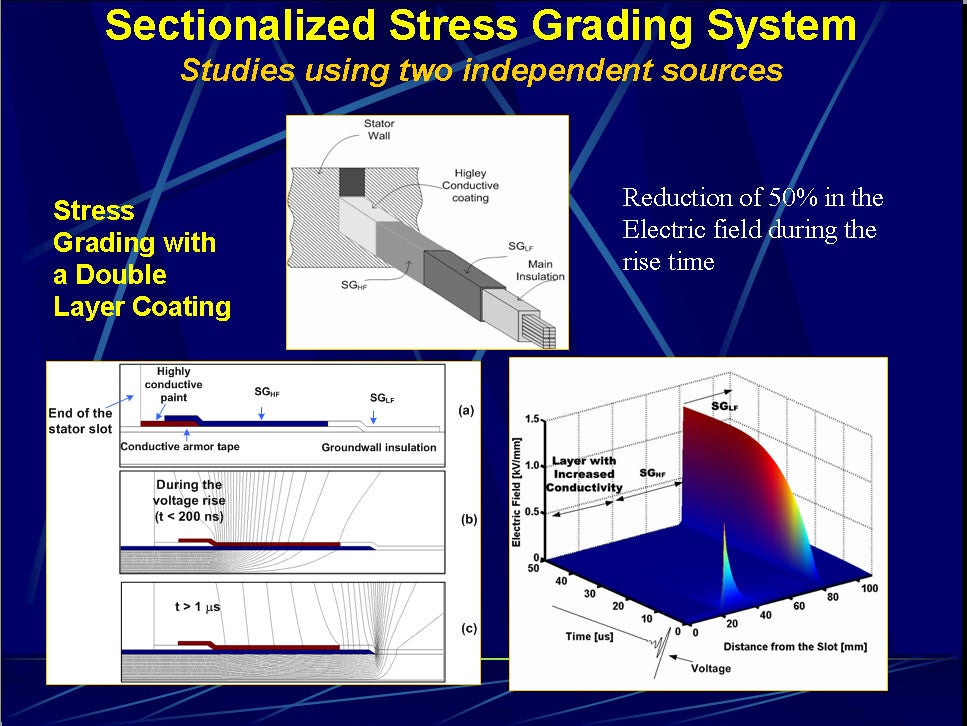

Stress grading system

A sectionalized, two-layer stress grading system using field dependent and constant conductivity (zinc oxide (ZnO) varistor materials and silicon carbide (SiC)) materials has been developed for inverter fed medium voltage stator coils. This unique design helps to grade the stress not only based on the field enhancement by power frequency voltages, but also to grade the field enhancements due to high frequency components. Current project deals with use of embedded conductive foils in ground-wall insulation to grade the surface electric field.

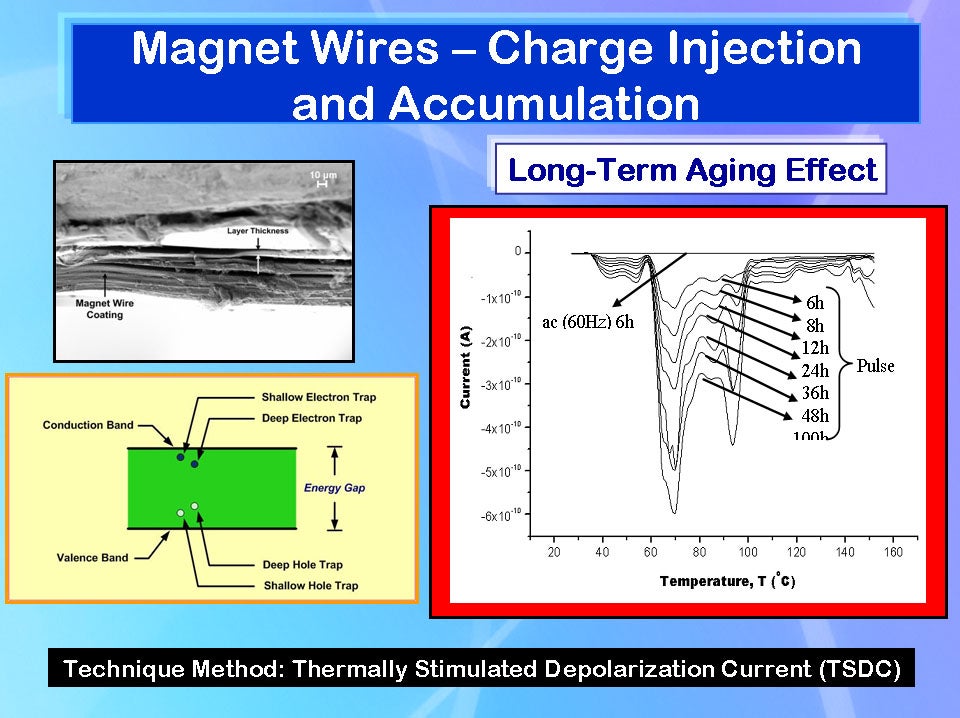

Enameled wire insulation

The insulation failure mechanisms of medium voltage inter-turn insulation of motors, as a consequence of pulse aging has been analyzed. To establish the residual strength of the bar samples, dc breakdown voltages are determined before and after the pulse aging. In addition, the thermally stimulated depolarization current (TSDC) is used to provide information about the relaxation processes, hence space charge effects in enameled wires. Further, the effectiveness of nanofilled enameled wires in resisting the degradation under pulse application is demonstrated.

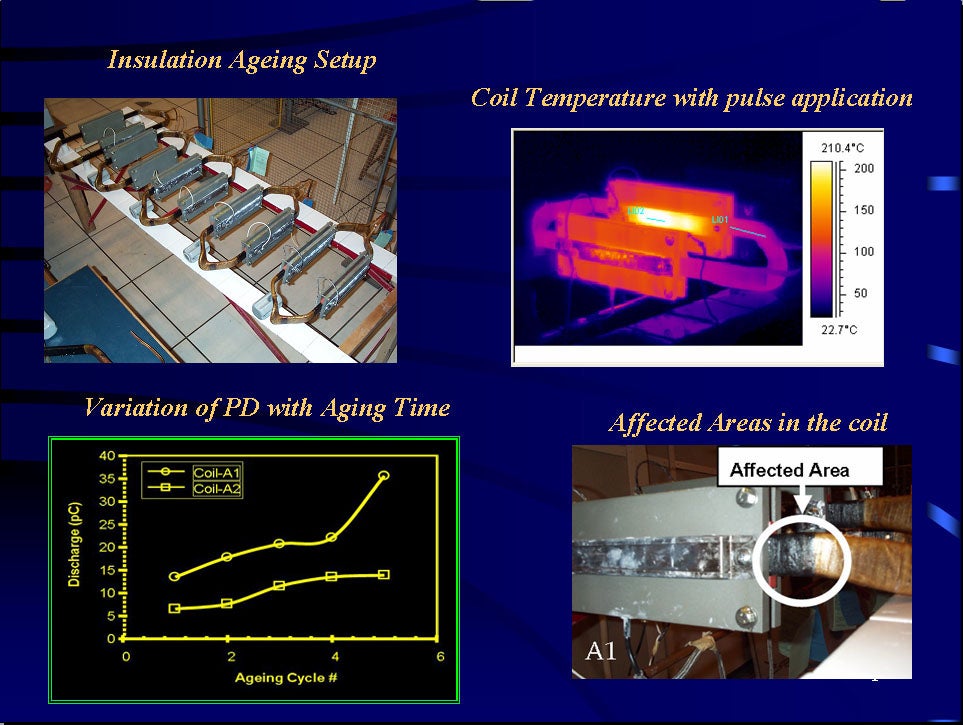

Groundwall insulation

Mechanisms of the aging and failure in stator bar groundwall insulation for motors fed with PWM-VSC have been analyzed. The aging experiments, based on accelerated aging techniques described in IEC 62068-1 and IEC 60034-18-32, are carried out under different pulse amplitudes and frequencies, and for different values of test temperatures. Also hotspot on the insulation surface and partial discharge activities of the insulation under power frequency and pulse application has been compared.