Field experiences have shown that transmission systems using voltage sourced converters (VSCs) with IGBT's can produce high frequency harmonic resonances in the VSC station environment. Modern cable terminations using non-geometric stress grading can be susceptible to degradation under these harmonics.

High frequency testing of XLPE cables and accessories

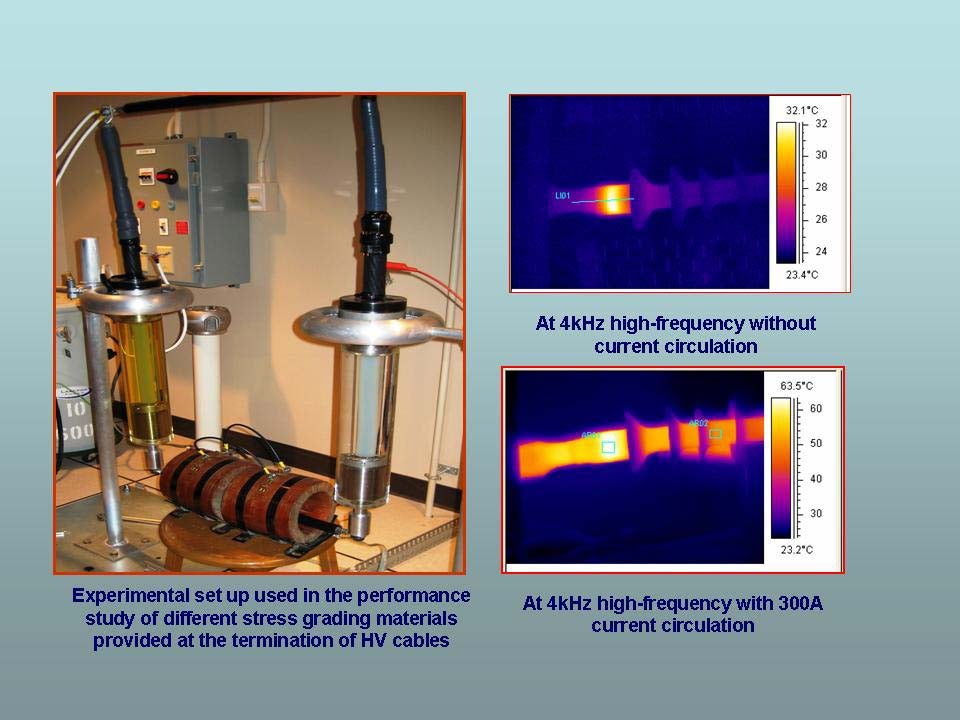

In this study a setup was designed to test cable terminations and XLPE cable accessories under conditions representative of high frequency harmonic resonance in the field. This unique setup can apply a superimposed power frequency (60Hz) and high frequency (6.5 – 7.5 kHz) waveform to the test termination/cable sample(s), and replicate conditions of high frequency harmonics in VSC systems. This setup can be applied to different insulation systems, in combination with current transformers to test under elevated temperatures from current circulation. Results have shown a wide variation in local temperature increase in the stress-graded (SG) areas of commercial terminations, attributable to differences in SG methods. A wide variation in thermal behavior exists among terminations utilizing different SG methods.

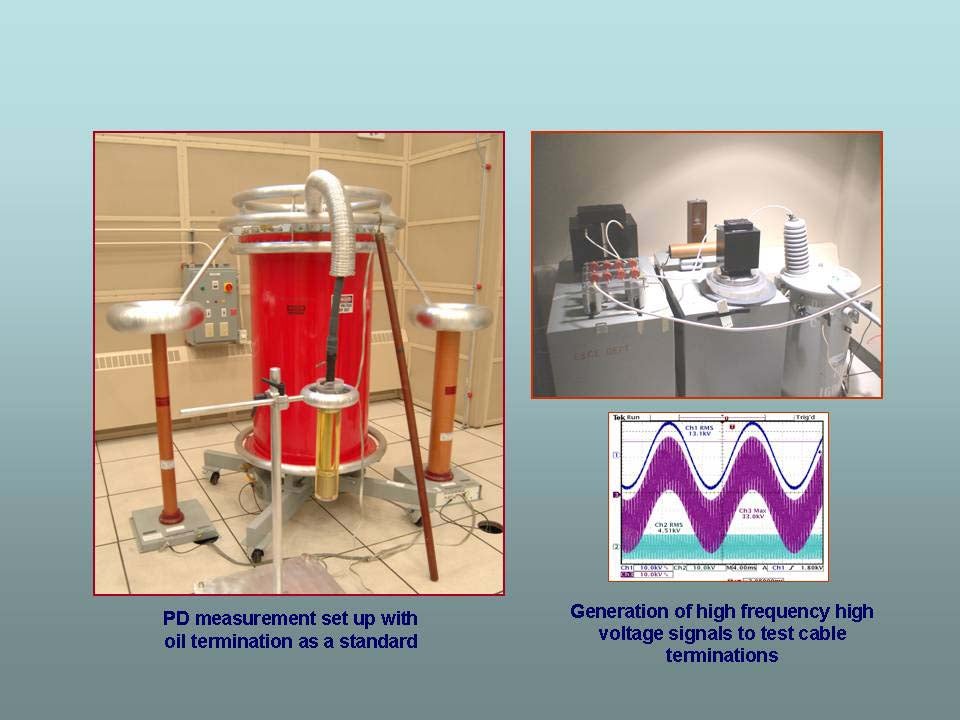

Partial discharge (PD) testing

In order to study PD breakdown, more specifically, PD testing of XLPE cables our lab uses the Oil-filled HaefelyTM test terminations with a discharge level of < 1pC (as shown in the left image). Additionally, research has been conducted using two Haefely test terminations that have been modified to allow testing to occur under current loading conditions. This testing method allows PD testing of cables/accessories to be conducted while current is circulated through a conductor loop, to analyze the effect of elevated conductor/insulation temperature on insulation degradation.