Turning table scraps into biodegradable, single-use plastics

New research turns food waste into eco-friendly plastics with the power of bacteria

New research turns food waste into eco-friendly plastics with the power of bacteria

By Media RelationsResearchers are using bacteria that eat food scraps to create a new kind of fully biodegradable plastic that reduces waste and could be less expensive to manufacture than current plastics are.

The team from the University of Waterloo says this new method produces plastics that are soft and flexible, leading to many potential applications such as food wrap, drug delivery and in the repair of damaged tissues and organs.

“Using food waste as food for bacteria which can produce bioplastics is a very exciting development,” said Dr. Trevor Charles, a professor in the Department of Biology at Waterloo, and one of the authors of the study. “This approach is significant because it has the possibility to reduce the cost of creating biopolymers.”

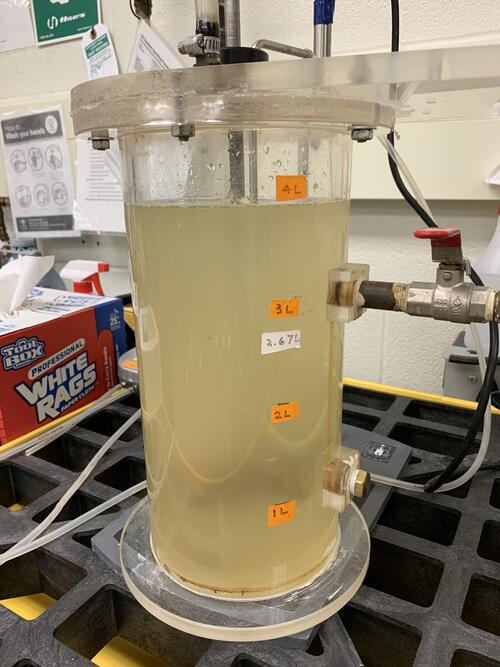

Image of biopolymers extracted from food waste

PHAs, the type of plastic that these bacteria can produce, are ecofriendly because they degrade naturally into benign byproducts in garden composts, agricultural fields, fresh or seawater and don't leave harmful plastic pollution or chemical residues behind. The research team is now trying to work out how to make these plastics in a cost-effective way.

“Currently, the process of breaking open the bacterial cells and recovering the polymer is costly. The team is working to develop an efficient and cost-effective extraction method that would make the overall production process more viable for large-scale commercialization,” said Dr. Tizazu Mekonnen, a professor in the Department of Chemical Engineering and an author of the study. “This research not only offers a pathway to reducing the environmental impact of plastic waste, it also supports a circular economy by turning food waste into a valuable resource.”

The next steps in this research involve optimizing and scaling up the extraction process for the biopolymer. The study, Production and Characterization of Biopolymer from Food Waste Using Pseudomonas putida, was recently published in ACS ES&T Engineering.

Read more

Upside Robotics secures new funding to accelerate the future of sustainable farming

Read more

Waterloo prof leads a team of researchers to improve water quality through a community-focused approach underpinned by technical excellence

Waterloo researcher Dr. Tizazu Mekonnen stands next to a rheometer, which is used to test the flow properties of hydrogels. (University of Waterloo)

Read more

Plant-based material developed by Waterloo researchers absorbs like commercial plastics used in products like disposable diapers - but breaks down in months, not centuries

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.