Integrating equipment reliability into long range planning

Generation Risk Assessment (GRA) is analogous to Probabilistic Risk Assessment (PRA), where a system reliability model (e.g., fault tree) is used to assess the operation of a power plant under various conditions. In GRA, the principal objective is to assess the impact of system and equipment unavailability and failures on the ability of the plant to produce power over time (as measured in megawatt-hours).

The reliability of systems, structures and components (SSCs) is the fundamental element that brings the concept of “risk” into long range planning and asset management.

Need to understand and quantify the change in plant and equipment reliability in the short- and long-term.

Integrated approach to GRA

Severe environmental and operating conditions in power plants have led to a variety of age-related degradation mechanisms, such as corrosion, fatigue, and creep, resulting in SSC damage and increased likelihood of failure over time. Time-dependent reliability predictions, from detailed degradation modeling or expert assessment are integrated into the GRA modeling approach using the following relationship:

where w(t) is the time-dependent failure frequency, q(t) is the unavailability, and \lambda(t) is the failure rate.

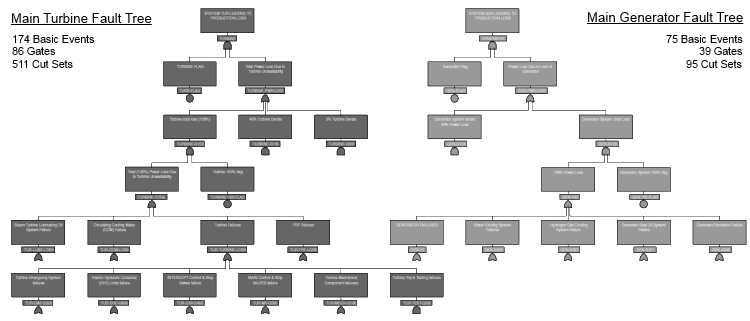

The relationship between the primary (component) failure events and system failure is characterized using minimal cut sets (i.e., unique system failure scenarios). The system failure frequency and probability are then estimated as the union of all the cut sets.

Other key information required for the analysis include

- Repair times and costs associated with each failure mode

- Magnitudes of derate and recovery times

- Plant capacity or output (i.e., cost of lost power production)

- Length of planning horizon and discount rate

Case study: GRA of the main turbine/generator

Objective: Investigate several long-term planning scenarios and identify the major sources of

generating risk in the Turbine/Generator system (i.e. risk ranking)

The GRA analysis was implemented in Microsoft Excel based on cut set output and basic event data from system reliability models in CAFTA.

Sample results

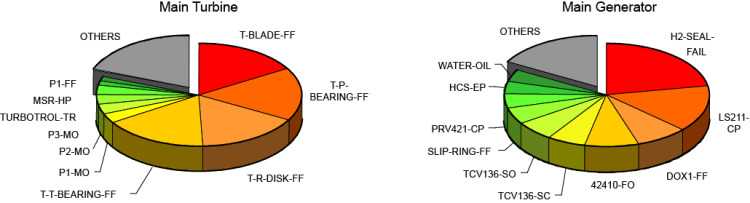

Risk ranking by primary (component) failure event

Summary results

| Main Turbine | Main Generator | |

|---|---|---|

| Unavailability | 1.32E-02 /year | 1.76E-03 /year |

| Forced Outage Rate (FOR) | 0.40 failures/year | 0.33 failures/year |

| Forced Loss Rate (FLR) | 1.58 %/year | 0.23 %/year |

| Lost Power | 117.8 GWh/year | 16.26 GWh/year |

| Total Generation Risk | $ 55.7 million | $ 7.7 million |

Value and benefits of GRA

- Provides a framework and methodology for integrating equipment reliability information into long-range planning and project portfolio evaluation

- Improves the asset management process by allowing plant managers and decision makers to more effectively evaluate long term maintenance and replacement decisions in a risk-informed setting

- Facilitates prioritization of capital and operations and maintenance (O&M) investments

- Improves both short- and long-term operational and investment decisions resulting in savings and revenue enhancement

- Enhances the flexibility and long range stability of the budget for plant improvement

- Results in more accurate identification and ranking of long-term economic risk among the various systems, structures, and components (SSCs) over the service life of the station

- Provides the capability to evaluate the long-term implications of identified degradation mechanisms in critical systems; an increasingly important input to plant decision-makers to ensure both plant safety and economic competitiveness

- Supports cost-effective and efficient operation of existing and new power plants