The primary goal of the Chair program is to advance research in the area of life cycle management (LCM) of nuclear power plant systems and renewal of energy infrastructure as a whole.

Life cycle management is an integrated approach to maximize plant value through a scientific approach to condition assessment, inspection, maintenance, and replacement activities that are systematically scheduled throughout the service life of a system.

Since system parameters, operational conditions, costs, benefits and other performance criteria tend to be uncertain, the concept of “risk” is integrated with the life cycle management philosophy. The term “risk” combines probability of an event with its consequence, and hence serves as a meaningful indicator of system performance.

Program overview

Life cycle management (LCM) is a process for the timely detection and mitigation of aging effects in systems, structures and components (SSCs) important to plant safety, reliability and economics. It is also considered a decision making process to choose the best and balanced alternative for asset management. In the nuclear plant, LCM defines in-service inspection and maintenance programs, outage/generation plans and cost and investment planning.

“Risk-Informed Decision Making” has become a cornerstone of the regulatory framework world wide. Uncertainties about the condition of existing assets and effects of aging are other significant confounding factors in life cycle management. Therefore, integration of techniques of risk and reliability analysis with LCM is important.

As many plants in Canada are approaching the end of life, cost-effective decisions are essential for the success of refurbishment projects. The balance between “fitness for service” (FFS) and “asset preservation” is evolving over time. Fitness for service is important for operation in the short term, whereas asset preservation is important for refurbishment. This suggests that LCM should be a dynamic model involving all aspects of uncertainties.

The main research objective of the Chair program at the University of Waterloo is the development and integration of reliability models with LCM of nuclear power plant systems, structures and components. The program is focused on

- Developing probabilistic models for risk analysis

- Benchmarking existing standards and FFS methodologies

- Solving a wide variety of practical problems related to the reliability of nuclear plant systems

- Supplying highly qualified personnel (HQP) to the industry

- Graduate Students (PhD, MASc), Post-Docs

- Education/Training of plant engineers (Undergraduates)

Fundamental research has focused on probabilistic risk and reliability modeling, stochastic processes, statistical estimation and extreme value analysis. Practical applications of the basic research include risk-informed LCM of fuel channels, steam generators, feeders and conventional systems, such as electrical generators and transformers. These applications have begun to yield considerable benefits to the operation and maintenance of nuclear power plants in Canada.

Research significance

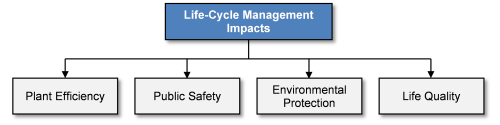

The refurbishment and renewal of nuclear reactors is a complicated process with several critical issues that require prudent planning and cost-effective management. The research program on risk-based life cycle management has significant potential for improving the performance and extending the service life of safety critical structures, and improving the effectiveness of operating costs in power generation plants. An additional benefit will be the improvement in overall fleet management capability. The general impacts of life cycle management are summarized in the figure below.

The direct benefits of the many projects undertaken by the NSERC-UNENE industrial research chair include:

- Effective fitness-for-service assessment of the reactor primary heat transport system (PHTS)

- Improved communication with the regulator about managing the risk associated with degradation

- Minimize cost penalties associated with increased inspection and outage duration

- Overall improvement in operational efficiency

Interaction with industry

A key objective of the IRC program is to facilitate the transfer of knowledge to industry through applications of the results of the fundamental research to practical industry problems. Please refer to the Industry Applications page for some specific examples.

Active collaboration and consultation with UNENE’s member industries takes place within conferences, workshops, and industry working groups, as well as through the publication of numerous technical papers and memoranda. Please refer to our Publications section for past and more recent examples.