Old and new come together in striking designs

Architecture students explore the potential of 3D printing with clay to make ‘completely unique’ creations.

Architecture students explore the potential of 3D printing with clay to make ‘completely unique’ creations.

By Brian Caldwell Faculty of EngineeringCombining cutting-edge technology with an ancient building material is producing impressive results at the University of Waterloo School of Architecture.

Students in a master’s class at the Cambridge school were challenged to explore the potential of a new 3D printer capable of making objects more than a metre high out of clay.

By the end of the fall term, they were showing off unique bricks for projects including a wall that whistles, an arch that doubles as a sundial and a beautiful façade featuring intricate loops.

“Everyone came out of it with something they’re super proud of – and surprised by,” said Victor Tulceanu, one of 18 students in the class.

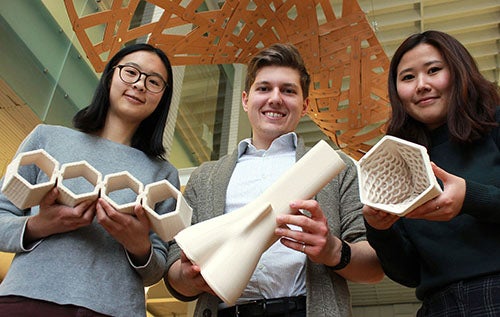

Graduate students Joanne Yau (left to right), Victor Tulceanu and Yesul (Elly) Cho show off the bricks they made out of clay using a new 3D printer at the School of Architecture.

The $20,000 printer, believed to be the only one of its kind in Canada, was so new when the class began that even professor David Correa didn’t know what to expect.

He assigned students in three-member groups to design a small wall out of bricks – or masonry façade components – and they set off to discover what was possible.

Part of the challenge involved learning about the properties and behavior of clay, then incorporating those factors into operation of the 3D printer - which was sponsored by MasonryWorx, an association of brick, block and stone professionals - and the bricks they designed using computer software.

The technology allowed students to slightly modify every individual brick, enabling the creation of an arch that concentrates light, and a wall that whistles different notes depending on which way the wind is blowing.

“There is no other way to make these kinds of façades without enormous cost and time,” said Correa, whose research involves the 3D printing of objects that move in response to changes in temperature, humidity and other environmental conditions. “They are completely unique.”

Yesul (Elly) Cho, whose team made an extremely intricate wall of interlocking bricks, got so much out of the class that she is continuing the work with a view to attending conferences and publishing academic papers on it.

“It’s fascinating to think that we’re the only ones in the world who have ever made this geometry with this machine,” she said of the capacity to produce one-of-a-kind components.

The students are especially struck by that concept since clay has been used as a building material for thousands of years.

“It’s cool that we’re advancing this really rudimentary material,” said Tulceanu. “Nobody would have thought of even trying to do something like this 3,000 years ago because it’s just too complicated.”

As a teacher, Correa is pleased that students had to both design and make their bricks, a process that required them to take practical factors and constraints into consideration.

He also sees great potential for clay 3D printing as an educational tool because the material is inexpensive, making it ideal for large-scale prototyping.

Correa and his students agree they’ve probably just scratched the surface so far, and there are plans to offer the class again next fall.

“The printer allows us to make much more complex geometry,” said Joanne Yau, whose team fabricated the ambitious arch/sundial. “To make this by hand or to extrude it would be virtually impossible.”

Read more

Waterloo co-op student applies engineering and tech skills at Caivan to support purpose-built housing and build land-development expertise

Read more

How Doug Kavanagh’s software engineering degree laid the foundation for a thriving career in patient care

Read more

Redefining capstone learning by bringing students, faculty and community partners together to tackle real-world challenges

Read

Engineering stories

Visit

Waterloo Engineering home

Contact

Waterloo Engineering

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.