Printing with wet clay

Architecture team produces showpiece privacy wall for high-rise office using 3D-printed bricks

Architecture team produces showpiece privacy wall for high-rise office using 3D-printed bricks

By Brian Caldwell Faculty of EngineeringThe reception area of a high-rise office in downtown Toronto now features a one-of-a-kind privacy wall thanks to a research team from the Waterloo School of Architecture.

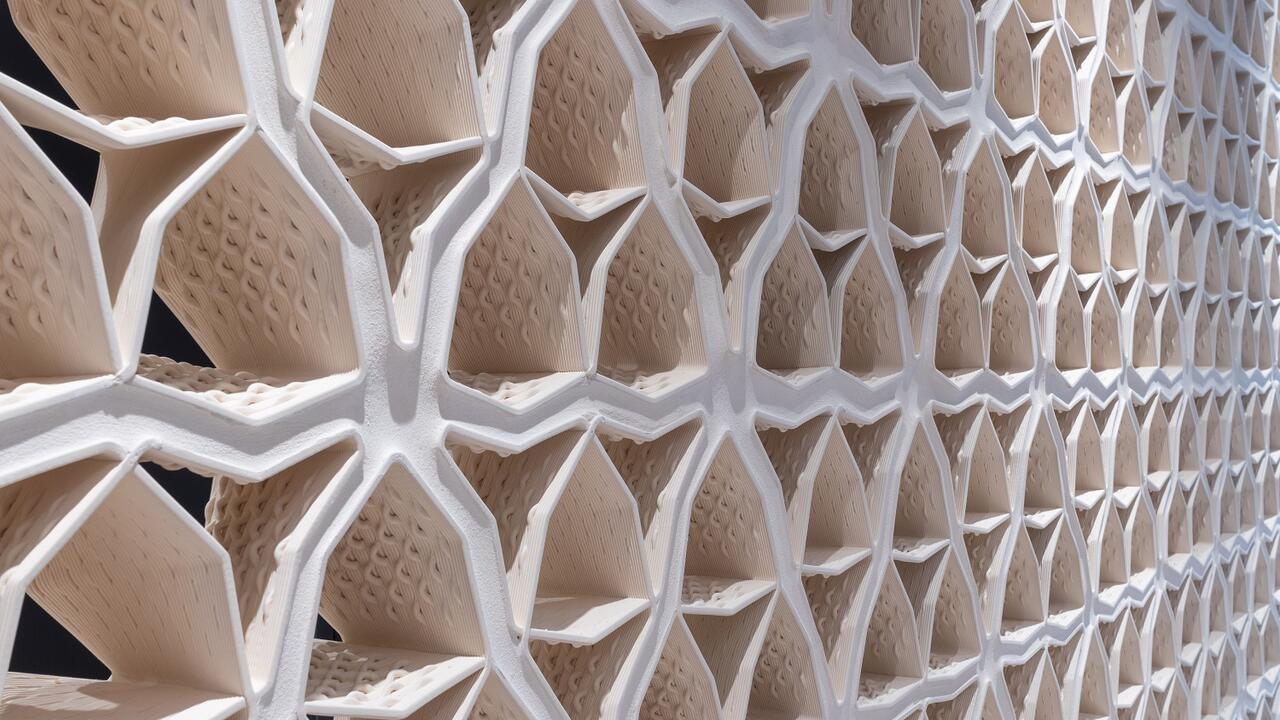

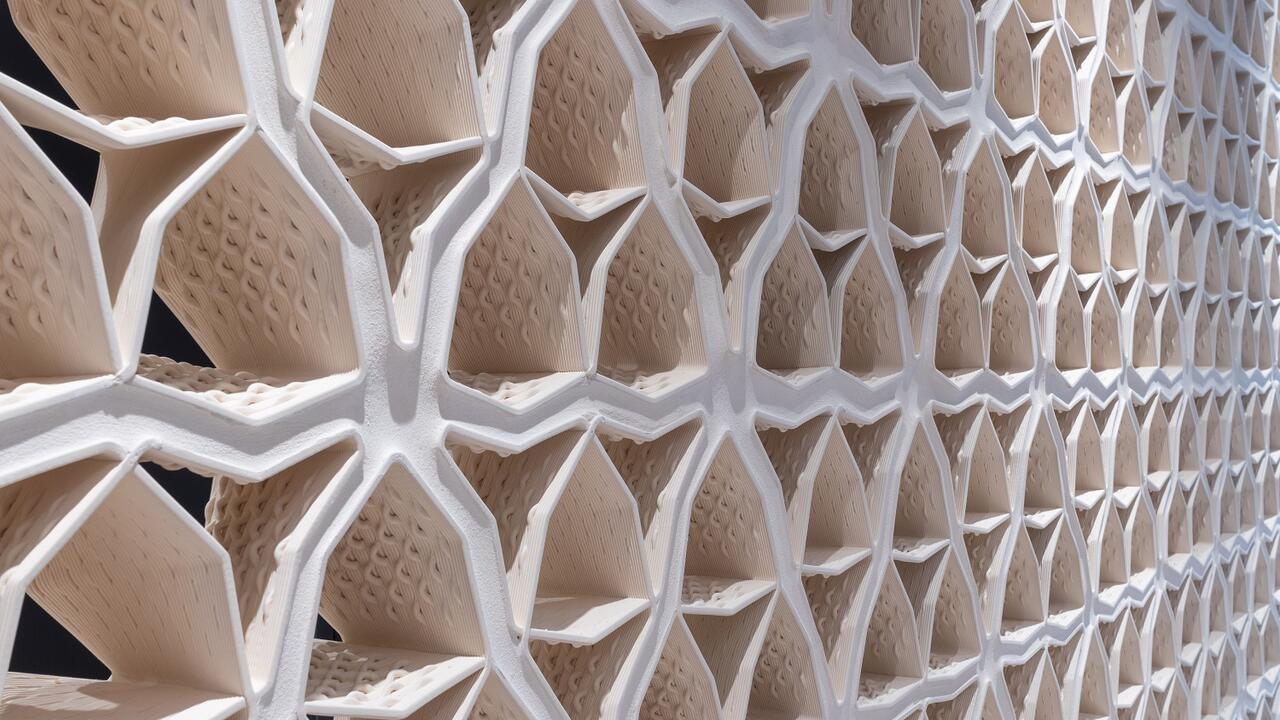

Comprised of 175 unique, interlocking bricks made of clay, the Hive project combined an ancient building material with modern digital design and 3D printing technologies.

Hive, a privacy wall made of 175 unique clay masonry units, was installed in a downtown Toronto office.

“This approach embraces the spirit of traditional ceramic craft with robotic precision, offering new avenues for material expression and geometric complexity within this field,” team members wrote in a project description.

The showpiece at the 24th-floor offices of Investment Management Corporation of Ontario at 16 York Street was developed after SDI Interior Design approached the architecture school.

Professor David Correa and his students have been working with clay since acquiring a 3D printer capable of making large-scale objects with it in 2018.

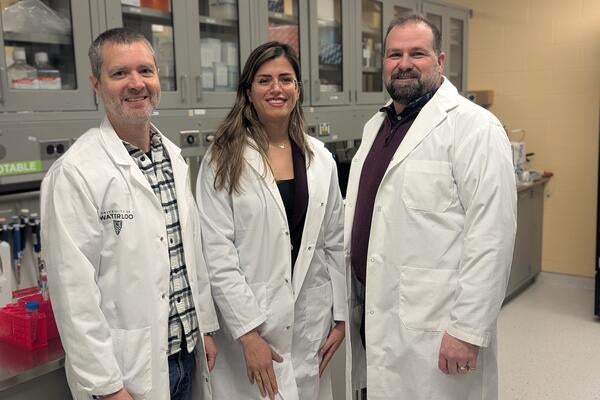

Graduate researcher James Clarke-Hicks and co-op student B. Mingyuan Ma work on the honeycomb wall, which required digital and physical iterations and multiple assembly mockups.

The honeycomb wall features variations in light and privacy as the apertures of its bricks – each one of them unique – gradually open and close.

"It was a great applied research experience," Correa said. "We were super thrilled when it all came together, and it worked out - even better than expected.”

Fabricating the wall required an iterative process using both digital and physical models, as well as the formulation of special clay mixes and multiple assembly mock-ups.

“While the messy and unstable nature of wet clay presents technical challenges in practical applications, these same qualities create opportunities to explore the unique aesthetic and functional possibilities offered by this fabrication process,” the team wrote.

In addition to Correa, the design and development team included alumni Ye Sul E. Cho, Ji Shi and Meghan Taylor, and graduate researchers James Clarke-Hicks and Isabel Ochoa.

Read more

Researchers engineer bacteria capable of consuming tumours from the inside out

Hand holding small pieces of cut colourful plastic bottles, which Waterloo researchers are now able to convert into high-value products using sunlight. (RecycleMan/Getty Images)

Read more

Sunlight-powered process converts plastic waste into a valuable chemical without added emissions

University of Waterloo researchers Olga Ibragimova (left) and Dr. Chrystopher Nehaniv found that symmetry is the key to composing great melodies. (Amanda Brown/University of Waterloo)

Read more

University of Waterloo researchers uncover the hidden mathematical equations in musical melodies

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.