Waterloo scientist advances research into e-textiles

Curtains that generate solar power and sleepwear that monitors a baby’s heart rate may be the future of nano-fabrics, says Waterloo researcher

Curtains that generate solar power and sleepwear that monitors a baby’s heart rate may be the future of nano-fabrics, says Waterloo researcher

By Kira Vermond Communications and Public AffairsImagine a sheer window curtain made of fabric that generates solar power for your home; sleepwear that monitors a baby’s movements and heart rate, and camouflage uniforms that actually transform to blend in with a soldier’s surroundings.

Sound far-fetched?

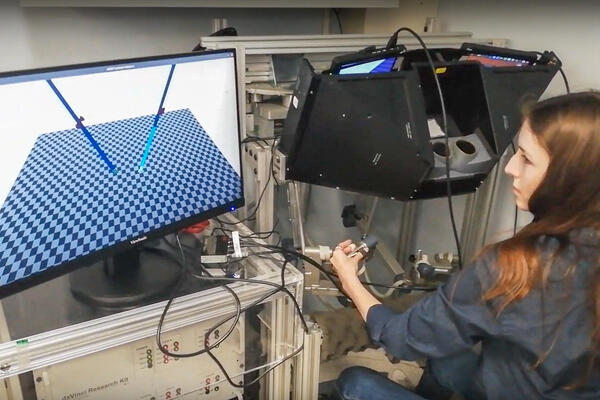

Although you won’t see any of these fabrics today, Irene Goldthorpe, a professor in the department of electrical and computer engineering, is now conducting nanotechnology research that could lead to leaps in electronic textile design.

Although you won’t see any of these fabrics today, Irene Goldthorpe, a professor in the department of electrical and computer engineering, is now conducting nanotechnology research that could lead to leaps in electronic textile design.

“As an engineer at Waterloo, I want to be working on things that have real world applications,” she says.

Nanowire thread

As a materials scientist, she creates new materials for electronic devices from solar cells to LEDs and electronic displays. Much of her work focuses on how to integrate minute metal nanowires into other materials and make their surfaces conductive. In the case of e-textiles, she has taken simple cotton thread and dipped it into a solution of nanowires. These wires look just like regular wire, except they are less than 100 nanometres in diameter and you need an electron microscope to see them.

She has already proven that the nanowire-coated thread is conductive and transfers energy. The next step, she says, is to engineer a device out of the thread.

Flexible and inexpensive

Although e-textiles already exist today – just look for LED shoelaces for kids on the store shelves this fall – Goldthorpe says her research could be a game changer.

“By using these tiny nanowires, the thread is more flexible and lightweight. Today’s materials are big, bulky and not as flexible,” she explains.

Goldthorpe is also researching ways to coat plastic and glass with nanowires so the material can conduct electricity while still allowing light to enter and leave. This work could be especially useful in creating next-generation solar panels. Today’s panels, while they’re functional, have some drawbacks: the electrode is expensive and brittle. Try to bend a solar panel now and the electrode will crack and degrade.

“The electrode we make with nanowires is flexible and much cheaper,” she says.

Read more

The Government of Canada announces funding to support critical research projects

Read more

With robotics, 3D technology, AI and more, Waterloo students are advancing the future of health care in Canada

Read more

New technology is five times more efficient than current desalination techniques

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.