Electric Plane Performance in 2024: How Many Hours Can Flight Schools Expect from the Pipistrel Velis Electro?

Flight schools earn revenue when planes are flying, so an important question is how many hours can they expect an e-plane to fly in a day? Future batteries and future e-planes offer bigger promises, but let’s look at the world’s only type certified electric trainer on the market today, the Pipistrel Velis Electro with its second-generation battery.

The assumption that you can get an hour of flying time for an hour of charging time is overly simplistic, as we noted in an earlier blog post. By landing with at least 30% SOC (state of charge) left in the battery, flight time will be less than an hour. Time on the ground between flights includes more than charging time. Inspections and briefings are required as well. So, how close to a two-hour cycle of flying and charging can you operate?

We decided to fly the Pipistrel Velis Electro at Sealand Flight in Campbell River, BC, consistently over a two-week period in August 2024 to find out.

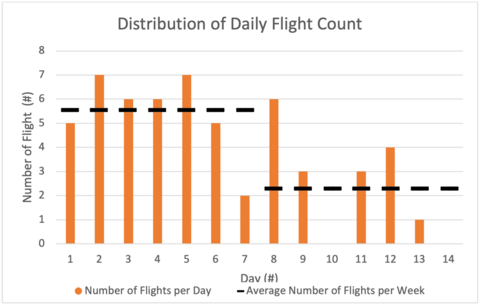

Graph 1 shows the number of flights flown per day. Three check and familiarization flights were flown on day 1 along with a regular pilot conversion flight and then the pilot’s first solo flight in the Velis Electro. The total of five flights on day 1 was either equaled or exceeded on each of the next five days. The pattern of five to seven flights per day was broken on day 7 when weather cut the day short with just two flights. Each flight typically consisted of various circuit or cruise exercises.

If you look at the weeks separately, 39 of the flights were in week 1 (5.6 flights per day) and 16 flights were in week 2 (2.3 flights per day).

Graph 2 presents the number of hours that were flown each day. The pattern is similar to graph 1, but the number is lower because flight times averaged 50 minutes, or less than an hour. The days with six or seven flights typically had five or six hours of flight time. Similarly, the days with three flights had just over two hours of flight time on average.

Overall, 45 hours were flown over the two-week period with a maximum of 6.2 hours and minimum of 0 hours per day. The average was 3.2 hours per day over the fortnight, or 4.4 hours per day in week 1 and 2.0 hours per day in week 2. If you exclude the two non-flying days, the average rises to 3.8 hours per day over the 12 flying days.

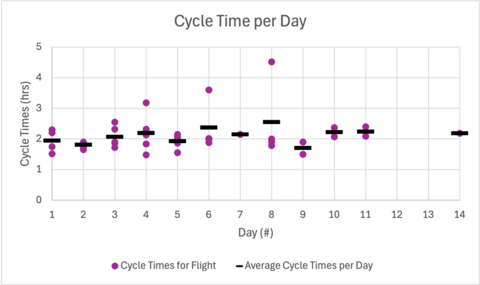

Graph 3 shows the time taken to complete the turnaround between flights. It is measured from the end of one flight until the start of the next flight. The turnaround time includes charging time as well as any required plane inspections and pilot briefings. The average turnaround time was 88 minutes or just under 1.5 hours. On a weekly basis, the average turnaround time was 85 minutes in week 1 and 95 minutes in week 2. On three occasions, the turnaround time exceeded two hours due to weather or operational issues such as a small bird strike that required a special inspection. The longest interval between flights was 233 minutes, or nearly four hours.

The average time to complete a full cycle from the start of one flight until the start of the next flight was just over two hours (125 minutes) (Graph 4). In the first week, the average time was a little faster (2 hours 2 minutes) and in the second week it was two hours and fifteen minutes. The details of an average flight include a flight time of 50 minutes which ended with an average state of charge of 38%. The minimum %SOC desired on landing is 30% and the pilots landed with a comfortable margin above that. Charging the battery took 54 minutes on average. The remaining time was used for checks, briefing, etc. Overall, a two-hour cycle was achieved when all factors went smoothly, but when any factor (weather, pilot, or operational) caused a delay, it exceeded two hours.

In summary, assuming a fly-charge cycle time of two hours, a 12-hour day can be expected to offer six slots for flights. Of course, in summer the longer days mean that you can easily get an extra flight in before 8:30, our typical first launch time. With the current generation of battery and a reserve of at least 30% SOC, flight times were under an hour (50 minutes) and the six flights would generate five hours of flight time.

If weather or operational factors restrict some of the time slots, the number of flights will be reduced accordingly. In this August two-week period, the weather offered generally fine weather for the first week and mixed weather with restrictions in the second week, including two days with no flying. Overall, the average flight time over the two-week period was over three hours per day with a range from zero to six hours per day. If you removed the two no-flying days, the average increases to nearly four hours per day. If this pattern was continued over 100 flying days in a season, the total would reach 400 hours.

Of course, multiple other factors affect flying time as well. The level of demand or pilots wanting to fly is important. Equally, the availability of instructors is critical if flight training is being arranged. Time management is also a critical factor as time for briefing and plane inspections can overlap with charging time to reduce the turnaround time between flights.

Each flight school has evolved its own culture related to pre-flight briefing, aircraft inspection and post-flight briefing times. Typically, fueling time is brief and less important. However, in the case of electric aircraft, the longer time required for charging the battery means that charging time is an important part of overall time planning. Flight schools will continue their evolution of flight preparation routines and decide whether electric planes and charging times are to become a part of their future culture, and influence how much flight time they get in a day.

Ultimately, whether electric planes can exceed four hours of flight time per day will depend on operational efficiency, weather conditions, and how well schools adapt to the specific demands of electric aircraft.