Theme Overview

Soft matter refers to organic materials (e.g., foams, emulsions, gels, liquid crystals) possessing a complex structure and exhibiting behaviour between that of solids and fluids. These materials find numerous applications in sensing, drug delivery, medical robotics and more. Using experiments and computations, researchers study the fundamental physics underpinning the macroscopic behaviour of these materials. They also explore their use in advanced manufacturing technologies (e.g.,3D printing), as well as mainstream industrial processing (e.g., pipeline flow of emulsions).

Professor Pu Chen

Professor Pu Chen is interested in researching supercritical fluids, including carbon dioxide, which have various industrial applications. Understanding interfacial properties of polymers in supercritical CO2 is vital for improving technology and energy efficiency. Chen, Director of the Biomedical Engineering and Energy Storage Group uses Axisymmetric Drop Shape Analysis-Profile to investigate these properties, optimize microcellular foaming process, and modify polymers.

Professor Milad Kamkar

Professor Milad Kamkar, Director of the Multiscale Materials Design Lab, designs novel processes to create new types of soft materials with unique morphologies. These soft materials include polymers, hydrogels, and multiphase emulsions. Other than traditional additive manufacturing techniques, Kamkar’s research group has developed a new technique called liquid streaming where structured all-liquid soft materials can be templated for fabrication of ultra-lightweight aerogels with hierarchical porosity. Utilizing cutting-edge advanced nanomaterials and/or polymers as the building blocks, these aerogels find application across diverse sectors, from electromagnetic shielding to wastewater treatment, thermal management, and oil spill remediation.

Professor Tizazu Mekonnen

Using chemical engineering tools, Professor Tizazu Mekonnen’s research group designs polymers from renewable resources such as carbohydrates, vegetable oils, CO2, and terpenes, for a wide range of applications that promote future economic development, energy efficiency, and environmental sustainability. Some of the key areas of research in Mekonnen’s lab include:(a) the efficient and sustainable conversion of biomass to polymer ingredients, (b) the design and development of high-performance sustainable plastics, elastomers, and thermosets, (c) the design of polymer products with recycling, biodegradation, and composting considerations, and (d) multi-phase and multifunctional polymer systems (polymer blends and composites).

Professor Mark Matsen

Professor Mark Matsen’s research has largely focused on molecular self-assembly in polymeric systems involving block copolymers. Block copolymer molecules consist of chemically distinct polymer chains (i.e., blocks) covalently bonded together, and they self-assemble because of a general tendency for unlike blocks to phase separate. When this happens, the unlike blocks form microdomains often with some intricate periodically ordered geometry. Not only do these molecules possess significant commercial applications, but they also represent a model system for studying general phenomena associated with molecular self-assembly.

Matsen is particularly known for his developments in polymer self-consistent field theory (SCFT). This state-of-the-art theory is capable of accurately predicting the detailed domain structure formed from block copolymer and/or liquid crystalline systems using microscopic models. SCFT has been immensely successful and, as such, has played a pivotal role in experimental studies, correcting experimental errors, and predicting behaviour later to be confirmed in the lab.

More recently, Matsen has been developing a novel simulation method known as field-theoretic simulations (FTS), which is able to improve upon the predictions of SCFT. It is capable of simulating large systems containing upwards of 100 billion molecules, whereas conventional simulations are generally limited to about a thousand molecules.

Professor Rajinder Pal

Professor Rajinder Pal investigates electromagnetic, mechanical and transport properties of different composite materials including emulsions, suspensions, and foams. Pal engages in experimental and modelling work to develop models which predict the properties of materials and use them to design processes for various applications. Pal has expertise in emulsions and works with a variety of industrial partners in the food, pharmaceutical and cosmetics industries. Pal designs foams for the food industry, fire extinguishers, insulation, and for use as packaging materials.

Pal is an expert at using suspensions and emulsions in the transportation of materials across long distances. For example, coal can be crushed and put into a suspension to be pumped through pipelines. Pal is interested in the science and engineering of materials.

Professor Alex Penlidis

One of Professor Alex Penlidis’ research interests is utilizing polymers to act as sensors to detect gases and other toxins. These sensors, called micro-mechano-electrical systems (MEMS), are also able to detect compounds underwater. Penlidis uses polymers that are sensitive and selective for specific gases or chemical analytes.

In this research, Penlidis collaborates with researchers from System Design Engineering and Electrical and Computer Engineering (Professors Eihab Abdel-Rahman and Raafat Mansour), who design the MEMS, while Penlidis utilizes his expertise in soft matter and advanced materials to design, synthesize and deposit a sensitive detecting polymer measured in nanograms to the device. This collaboration has extensions in environmental and agricultural applications and can be useful in detecting greenhouse gases (GHG).

Professor Elisabeth Prince

Professor Elisabeth Prince Director of the Prince Polymer Materials Lab designs synthetic biomimetic hydrogels for biomedical applications. She creates biomimetic nanofibrous gels for tissue engineering, drug delivery, and regenerative medicine. In one of her research interests, she utilizes nanofibers that act as scaffolding for regrowth and healing of damaged heart tissue. Her research group also fundamentally studies the structure-property relationships of filamentous biomaterials.

Professor Hamed Shahsavan

Professor Hamed Shahsavan is designing novel smart soft materials that are programmable and respond to different stimuli such as heat or light. Shahsavan, Director of the Smart Materials for Advanced Robotic Technologies Research Group is designing such new advanced materials using four classes of soft matter, namely, liquid crystals, polymers and hydrogels, surfactants, and colloids for use in medical robotics applications. The focus of the research with these materials is predetermined shape changes that give a robot functionality. The soft matter used in robots can range in functionality from being used to create artificial muscles to mimic the softness of cells. He is developing robots that are stiff enough to perform tasks like manipulation of tissues and cells but soft enough to non-invasively interact with them.

Professor Michael Tam

Professor Michael Tam’s research group works with nature-inspired sustainable materials such as plant-based fibers used to produce cellulose nanocrystals (CNCs). The CNCs can be modified by grafting polymer brushes or nucleating metallic and inorganic nanoparticles on their surface for scalable applications such as antimicrobial agent, food processing, healthcare and beauty products, agriculture, and wastewater treatment. These soft materials derived from renewable resources are excellent carbon sinks and using them for product development will contribute to the net zero carbon economy.

The Laboratory for Functional Colloids & Sustainable Nanomaterials led by Professor Michael Tam seeks to develop the next generation of technologies that will contribute to the United Nation Sustainable Development Goals. These include low energy dehumidification technologies, sustainable and water-proof paper packaging system, and sustainable air purification technologies for the building and construction industry.

Professor Aiping Yu

Professor Aiping Yu utilizes soft matter engineering on polymers. She adds nanofillers (nanoparticles, Nanotube, nanofibers, etc) to make multi-functional nanocomposites and nanotechnology expertise to enhance polymer's mechanical and electrical properties. Yu adds 2D materials such as graphene or Mxenes to polymers to create shielding that will protect biomedical devices from electromagnetic wave impacts. This could also be applied to clothing to shield people from the impact of radiation from an electromagnetic wave.

Yu, Director of the Applied Carbon Nanotechnology Laboratory is also applying graphene to pipelines in an effort to reduce pipeline maintenance time. Yu uses chemically functionalized graphene in pipe liner applications to reduce corrosion in critical pipelines.

Professor Evelyn Yim

Professor Evelyn Yim utilizes soft matter such as hydrogels combined with nanotechnology to design biomaterials for tissue engineering. Yim’s research group investigates how nano-scale surface features change cell behaviour and cell fate, as well as how to control the fate of a cell with topographical cues. Yim, Director of the Regenerative Nanomedicine Lab uses soft matter to mimic the tissues of the human body for biomedical applications in vascular, neural and cornea tissue engineering. Yim is a leader researcher investigating the use of synthetic materials for altering stem cell behaviour and differentiation.

Professor Boxin Zhao

Professor Boxin Zhao explores aspects of matter that fall between pure liquid and pure solids. He designs hydrogels, emulsions, surfactants, and colloids, which are typical subject of soft matter. He uses soft mater to design functional materials towards advanced manufacturing and sustainable development. Zhao, Director of the Surface Science and Bio-nanomaterials Laboratory uses polymers in his soft matter research. Zhao is advancing fundamental science by looking at the liquid-like and solid-like states of matter to design novel materials. Zhao creates novel materials, functional coatings and adhesives for industrial, robotic, and biomedical applications.

In order to use the hydrogels in biomedical applications, Zhao investigates the adhesion, biocompatibility and micromechanical properties of hydrogels under differing conditions.

Research Highlights

Mark Matsen: Field-theoretic simulations of polymeric microemulsions

Alloys are solid mixtures of metals with tailored material properties. Unlike metals, dissimilar polymers are generally immiscible due to the lack of translational entropy. This is why plastics generally need to be separated into different types before they can be recycled. Still, as water and oil can form a microemulsion with the addition of soap, immiscible polymers can be compatibilized with the addition of diblock copolymers (the polymeric analogy of soap molecules). Unfortunately, progress into polymeric alloys has been limited by the fact that they are exceptionally difficult to simulate, due to the size and number of molecules involved. Professor Matsen and his students are overcoming this challenge with the development of field-theoretic simulations. The video below shows a simulation of two different polymer-rich domains with a microemulsion coexisting in between. The simulation involves 100 billion molecules, which is far beyond the capabilities of conventional particle-based simulations.

The video above shows a simulation of a liquid containing approximately 50 billion “blue-coloured” polymers, 50 billion “orange-coloured” polymers, and 1.6 billion diblock copolymers which have created a microemulsion of blue and orange polymers in the middle third of the simulation box.

Michael Tam: Harvesting freshwater using sustainable nanomaterials

Freshwater scarcity is becoming a global challenge for humankind. Atmospheric water harvesting is an innovative solution to meet the rapid and growing demand for clean water.

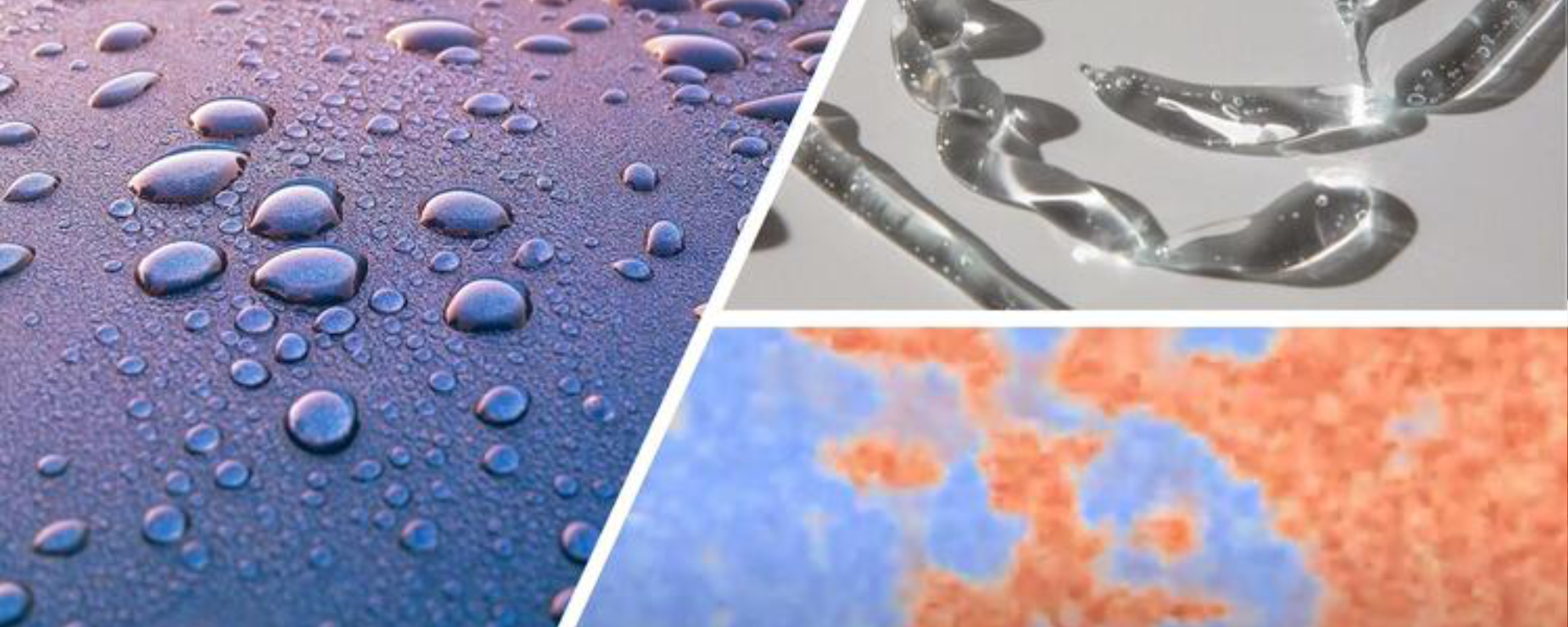

Capturing water from air happens in nature, for example, water droplets captured on the back of fog beetles. Inspired by the beetle’s back, Prof. Tam’s research group recently disclosed a unique superhydrophobic surface with tunable nanoscale hydrophilicityusing a structured CNC/wax Pickering emulsion as building blocks. Their surface collects water three times as fast as a beetle's back.

Water vapour condenses forming droplets that grow rapidly on a unique superhydrophobic surface with tunable nanoscale hydrophilicity.

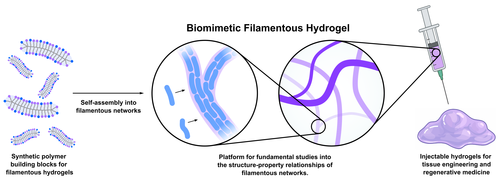

Elisabeth Prince: Networks of protein nanofibers are ubiquitous in biological systems

Synthetic filamentous hydrogels can serve as a scaffold for cells in tissue engineering applications.

The synthetic filamentous hydrogels’ ability to mimic biological tissues makes them excellent materials for tissue engineering. Professor Prince and her students are designing synthetic polymer building blocks that self-assemble into biomimetic hydrogels, enabling precise control over network architecture. They investigate how the architecture of synthetic filamentous networks impacts their functional properties, and explore applications of these materials in regenerative medicine.

Milad Kamkar: Liquid-in-liquid printing

Aerogels are a flyweight amongst high-performance materials. Dr. Kamkar devised new types of ultralight aerogels with unique morphologies. This was achieved by the fabrication of structured multiphase liquids via two novel processes. The first is liquid streaming. The second, liquid-in-liquid printing is shown in the below video.