Thinking inside the box

Biomedical Engineering (BME) students learn to translate on paper concepts into reality in the second-year design course, BME 261: Prototyping, Simulation and Design. Through hands-on design projects, students develop essential engineering skills in fabrication, technical communication, teamwork and problem solving.

“Design starts with an idea, and execution brings it to life,” said course instructor Dr. Calvin Young. “This assignment challenges students to put the skills they’ve been developing into practice and build something.”

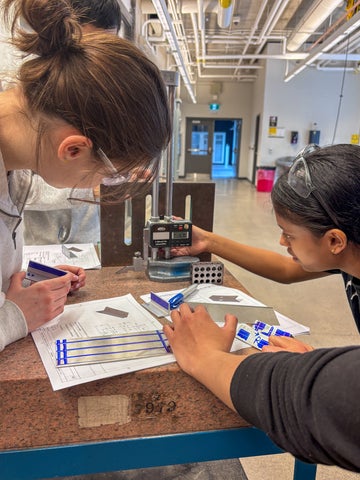

In the Engineering 7 Machine Shop, students are provided with technical drawings for a box and the raw materials and tools to build it. From there, they apply material fabrication techniques, like measuring, cutting, punching, bending, and machining, to build their confidence and competence in an engineering lab environment.

“They’re learning how to create a specific design, but also developing their instincts as designers,” said Young. “Each student brings their approach and interpretation, which leads to different challenges that must be identified and solved in real time.”

As students work through the process, they gain experience reading technical drawings to learn the details critical for ensuring the fabricated components fit together when assembled. It puts into practice key concepts like datum points, the reference position used to anchor design elements and tolerances, which is the allowable variation in measurement to maintain functionality of the design. Eventually, they will produce technical drawings for others to follow, so this training highlights the qualities of accurate and interpretable documentation.

Some fabrication techniques are deceptively simple, like punching a hole in the sheet metal, but demand a high level of precision. When asked about the most challenging aspect of the project, one student noted, “Punching the holes so the pieces will align when put together, it’s a lot harder to get it right than I anticipated.”

Every step needs careful attention, reinforcing the importance of safety, proper technique, and teamwork in the lab environment. After making their cuts, students must remove burrs, the sharp, raised edges left behind, to make sure the surfaces are smooth and safe to handle. The final steps involve folding the metal edges and preparing the pieces for riveting, ensuring each component fits together seamlessly in the final assembly.

Young recognizes that this assignment helps to scaffold skills that will be used later in their degree, on co-operative work terms, and leading into the Capstone Design Project. “The result is more than a finished box; it’s the sense of accomplishment and the development of key skills essential to becoming a professional engineer.”

Students carefully measure materials

Punching holes in the sheet metal