Case Implementation Storyboard in ME 380

|

Course: Mechanical Engineering Design Workshop (ME 380) |

Subject Area: Manufacturing, Product Design |

|

Case: Dalsa Harmony Camera Design (WCDE 00221) |

Department: Mechanical and Mechatronics Engineering |

|

Source: Teledyne Dalsa Inc. |

Faculty: Oscar Nespoli |

|

☒ |

Case study (Module 1) |

☒ |

Software Requirements & Specification (Module 2) |

☒ |

Teaching Note (TN) |

Case Background

The Dalsa Harmony Camera Body Part Design case study was developed in 2013 and intended for use in Mechanical Engineering and System Design courses covering topics such as design, manufacturing and heat transfer. The scope and specific topics covered by the case study are broader than the base material taught in the targeted courses. The case documents the design of a camera cover, the parts fabrication process, and a heat sink thermal analysis by Teledyne Dalsa Engineers and University of Waterloo coop student.

The Harmony camera body part design is based on Dalsa’s existing camera and specifically targets reduced production costs with comparable performance, scalable component architecture and lower bill of materials (BOM) costs. The project design focuses on the camera assembly, specifically reducing fabrication costs of the Harmony camera body components (H-Section, a 3D printed model of which is shown in Figure 1) while maintaining adequate heat transfer performance. The H-section is the structural housing to which key electronic components are attached, and it transfers heat away from these components via an internal heat sink bridge. In the existing camera, the H-section is manufactured from billet aluminum. A more cost-effective solution was desired for the Harmony camera.

In ME 380, the student used Design for Manufacture and Assembly (DFMA) methodology to simplify Harmony camera mechanical parts in terms of minimizing the number of parts, and minimizing the time and therefore costs of the assembly process. The case solution modules also cover topics in material selection and cost estimation, presenting trade-off decisions for alternate designs. Case materials include the case study itself, solution modules, teaching note and presentations.

Course Description

The case was used in the mechanical engineering design course (ME 380 - Engineering Design Workshop) in fall 2013 to instruct 87 students. The course consisted of both lectures and other case study analyses. During the lectures, the topics in the competency material were discussed. That formed the basis for the discussion of the case studies by student teams during case delivery.

The course (ME 380) is a third year design project core course. The Dalsa case was used to emphasize design for manufacturing concepts and provide a real-world application of manufacturing process analysis and cost estimation during product design. Students were provided with a sample 3D printed version of the mechanical part, Figure 2. The Dalsa Harmony Camera Design case study was assigned during the last week of the term after covering the needed theoretical concepts in the course.

Preparation

The case and individual assignments were provided to the students one week in advance of the implementation date, after an introductory lecture on DFMA. During the individual assignment phase, questions were designed mainly to demonstrate students’ ability to use appropriate knowledge and skills to: identify, formulate, analyze and develop substantiated solutions to a real-world problem. The students worked individually and in teams to analyze the problem and come up with their own recommendations about the manufacturing process and estimated cost. Often, individual study and preparation are followed by small group discussions, either in or outside of class. In this implementation, the class instructor (Nespoli) presented the case.

The class presentation focused on addressing most of the questions given to the students as part of their individual preparation assignments. Students were assigned to a team of 4 people and asked to discuss their individual answers in these teams in class, spending roughly 10 minutes on each question. The small group discussions facilitated the development of the students’ ability to verbally communicate complex engineering concepts to group members. As part of the small group discussions, a number of different manufacturing methods for the H-section were suggested and discussed in class.

Student Reaction

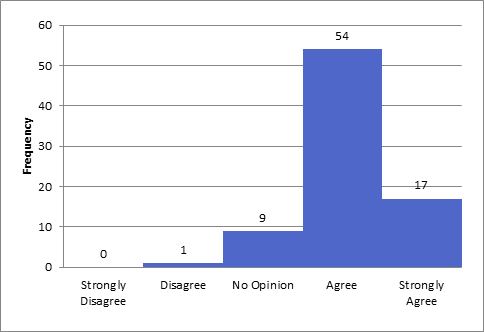

At the end of the case study in ME 380, students were asked to complete a feedback survey; 81 of 87 students responded. They were asked to respond to 5 questions on a Likert scale, from 1 (strongly disagree) to 5 (strongly agree). Figure 3 shows the student response to question 1: This case study was an engaging application of these specific course topics. The majority of students either agreed or strongly agreed with this statement. Engagement is a strong prerequisite for learning, and case studies provide a real-world application of course topics which students respond to. When asked to expand on their responses, students most often cited the strong fit between the case study and the course material. The numerical average of the student responses for this question was 4.3.

Question 2 further explored the connection between the case and the course material: This case study improved my appreciation for the relevance of these specific course topics. Similar results were obtained, with a numerical average of 4.2. Students highlighted the strong connection between the theoretical concepts discussed in class and the real-world practical example in the case.

Question 3 addressed student perception of their understanding of the material: This case study helped me understand these specific course topics. The numerical average of these responses was a little lower, 3.7. While students appreciated the application of course material, and one student commented on the increased perspective the case provided, a closer connection was desired. Two interesting responses were that a “high level [treatment] does not help understand low level concepts” and that while this was related to course content, “it feels unrelated since we don’t have design questions outside of this.” This hints that more time spent on the case and/or a design approach may help.

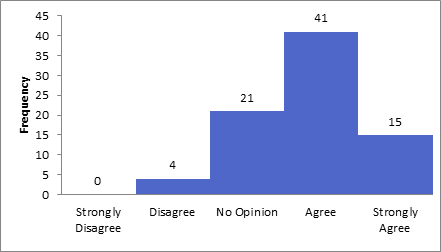

Question 4 addressed the perceived value of small group discussions: Small group discussions of the case helped me understand the specific course topics. Figure 4 shows the distribution of responses for this question. The numerical average of these responses was 3.6. Positive responses included the fact that the discussions “created an interactive environment with classmates” and “helped to clear the doubt and solved problems that couldn’t be solved sitting alone.” The primary reason for neutral or negative responses was the lack of time for these discussions.

This is an important point. To get the most out of this learning approach, more time is required for discussion. In business school applications, students are more familiar with the case approach and are trained to have these small group discussions before class, so that class time can be devoted to full class discussions. This is not feasible for the present situation, where only one or two cases are used in a class. This means that more class time should be set aside for small group discussions, which would require removal of some course content. A trade-off is necessary between content and case learning objectives.

Figure 3: Student response to question 4: Small group discussions of the case helped me understand the specific course topics.

Students were also asked to provide general feedback for improvement of the case study and case activities. About half of the respondents suggested different time allocations. The amount of time available to present the case and the logistics should be cut back, including the presentation of background material, and the case should be introduced earlier in the term to allow for more guidance on what was expected. This would make the discussions more efficient. Some requested a more challenging problem, while others suggested a more open-ended topic, with less detail provided, might provide more scope for discussion.

Key Takeaways

The results of the first implementation of this case study are encouraging. The students appreciated the added learning provided by this approximation to practice to lectures and examples provided by the instructor. The 3D printed artifact was an important focus of the group discussions as confirmed by observations by the instructor. One of the 13 groups working on the case study arrived at the design solution adopted by Dalsa. A possible extension of the case study would be to have groups estimate the manufacturing cost of the new process.