Creating mini devices for maximum biomedical impact

John Yeow is driven to solve real-world problems that lie deep within the human body

John Yeow is driven to solve real-world problems that lie deep within the human body

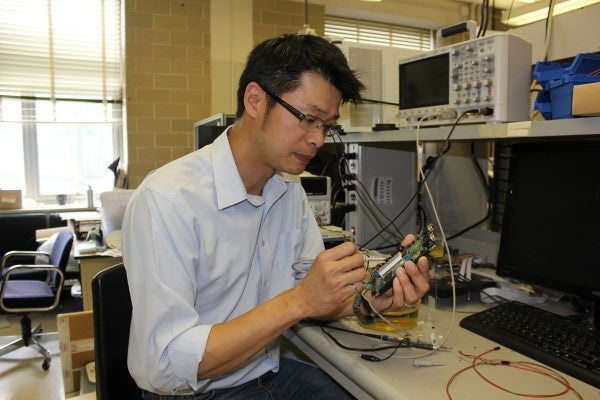

By Brian Caldwell Faculty of EngineeringSystems design engineering professor John Yeow is driven to solve real-world problems that lie deep within the human body. As the Canada Research Chair in Micro and Nanodevices, much of his work focuses on technology aimed at diagnosing and treating diseases like cancer. And the smaller the technology, the better.

In his equipment-filled laboratory, more than a dozen graduate students and co-op students are developing carbon nanotubes, scrutinizing microscopic chips, manipulating tiny mirrors and putting prototypes through a battery of testing.

Some of them are busy working on a two-dimensional array of ultrasound transducers, each transducer a fraction of a millimetre wide. The briefcase-sized prototype provides clearer images than conventional ultrasounds, and it provides them faster because there’s no need to scan a wand back and forth. “You put it on the patient, take a snapshot, and it provides you with 3D image information,” says Yeow.

By visualizing what lies beneath a patient’s skin, the device helps doctors arrive at more accurate diagnoses. It also takes some of the guesswork out of surgery, allowing surgeons to see exactly where a particular blood vessel lies before making an incision, for example.

So far, so good. But Yeow has his sights set on something even smaller.

“Now we want to further miniaturize the device, package it, and ultimately put it at the tip of the catheter,” Yeow says.

And that’s where the real challenge lies. Integration is a huge problem, he explains. While creating the transducer that generates ultrasonic waves might be relatively straightforward, integrating the electronics that control it is not so easy. Then you need to fit them both into a device the diameter of a pencil — all without compromising performance.

In another corner of the laboratory, a team is developing radiation sensors based on nano-carbon materials that change conductivity as radiation intensity increases. That allows health-care professionals to calibrate the X-ray machines used for radiation therapy, ensuring they deliver exactly the right dose.

The technology is currently being tested at Kitchener’s Grand River Cancer Centre. The next step, says Yeow, is creating sensors that could be placed within the patient’s body, allowing doctors to assess radiation doses in real time during treatment.

Yeow came to Waterloo as a newly-minted PhD, attracted by the University’s inventor-owned intellectual property policy. Because the policy makes commercialization easy, the prototypes he develops in his lab can more quickly make an impact in the real world, including patients at the Grand River Cancer Centre.

When he arrived 11 years ago, he also discovered the strength of Waterloo Engineering undergraduates. As well as providing a rigorous academic program, Waterloo ensures its engineering students gain real-life working experience. That means Yeow can hire co-op students who have already spent a term in a hospital or medical lab.

“They know about device development. They also know about clinical concerns. So when they come into my lab, they require minimal training,” he says. “They really impress me and do incredible work.”

Read more

Two University of Waterloo affiliated health-tech companies secure major provincial investment to bring lifesaving innovations to market

Read more

Researchers engineer bacteria capable of consuming tumours from the inside out

Hand holding small pieces of cut colourful plastic bottles, which Waterloo researchers are now able to convert into high-value products using sunlight. (RecycleMan/Getty Images)

Read more

Sunlight-powered process converts plastic waste into a valuable chemical without added emissions

Read

Engineering stories

Visit

Waterloo Engineering home

Contact

Waterloo Engineering

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.