Farm manure finds new life as a source of green energy

Curiosity on a summer drive through local farm country helped inspire an idea that could change the way homes are heated and industries are powered

Curiosity on a summer drive through local farm country helped inspire an idea that could change the way homes are heated and industries are powered

By Brian Caldwell Faculty of EngineeringCuriosity on a summer drive through local farm country helped inspire an idea that could change the way homes are heated and industries are powered.

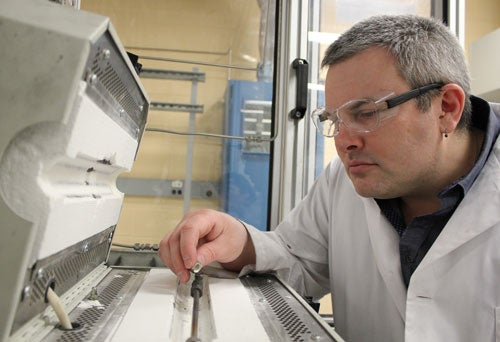

The concept began to take shape when David Simakov, a professor at Waterloo Engineering, stopped at a farm to see how biogas was being produced from manure, then burned in generators to produce electricity.

That productive use of waste made him wonder if it would be possible to do even more for the environment by upgrading biogas into renewable natural gas to be added to the existing energy supply system.

More than a year later, Simakov and his colleagues are now developing technology to make that innovative idea practically and economically feasible.

Using manure as a renewable energy source would reduce particularly harmful gases released by naturally decomposing manure when it is spread on farm fields as fertilizer and partially replace fossil natural gas, a significant contributor to global warming.

“There are multiple ways we can benefit from this single approach,” says Simakov, a professor of chemical engineering at Waterloo. “The potential is huge.”

The technology could be viable with several kinds of manure, particularly cow and pig manure, as well as at landfill sites.

And in addition to use by industries and in homes, renewable natural gas produced from manure could replace diesel fuel for trucks, a major source of greenhouse gas emissions.

“If it was implemented on a large scale in the transportation sector, the impact could be enormous,” says Simakov.

To test the concept of producing renewable natural gas, Waterloo researchers built a computer model of an actual 2,000-head dairy farm in Ontario that collects manure and converts it into biogas in anaerobic digesters.

Some of that biogas is already used to produce electricity by burning it in generators, reducing the environmental impact of manure while also yielding about 30 to 40 per cent of its energy potential.

By upgrading, or converting, biogas from manure into renewable natural gas, researchers hope to take that approach a significant step further.

That would involve mixing biogas with hydrogen, then running it through a catalytic converter. A chemical reaction in the converter would produce methane from carbon dioxide in the biogas.

Known as methanation, the process would require electricity to produce hydrogen, but that power could be generated on-site by renewable wind or solar systems, or taken from the electrical grid at times of low demand.

The net result would be renewable natural gas that yields almost all of manure’s energy potential and also efficiently stores electricity, but has only a fraction of the greenhouse gas impact of manure when it is spread on fields as fertilizer.

In addition, the liquid residue from manure after the generation of renewable natural gas could be used as fertilizer, with the remaining solids serving as animal bedding.

“This is how we can make the transition from fossil-based energy to renewable energy using existing infrastructure, which is a tremendous advantage,” says Simakov, who collaborates with fellow chemical engineering professor Michael Fowler.

The modelling study showed that a $5-million investment in a methanation system at the Ontario farm would, with government price subsidies for renewable natural gas that are already in place, have about a five-year payback period.

Researchers are developing the technology after achieving encouraging results on a small scale in the lab. Challenges include designing an optimal configuration for the catalytic converter and synthesizing a suitable catalytic material.

“Our motivation is enabling a transition from the fossil-based energy infrastructure to a renewable energy infrastructure,” Simakov says

Also involved in the work are post-doctoral researcher Sean Walker, master’s student Duo Sun and three engineering undergraduates – Dominika Kidon, Ashar Siddiqui and Amrit Kuner – who contributed for their Capstone Design project.

University of Waterloo researchers Olga Ibragimova (left) and Dr. Chrystopher Nehaniv found that symmetry is the key to composing great melodies. (Amanda Brown/University of Waterloo)

Read more

University of Waterloo researchers uncover the hidden mathematical equations in musical melodies

Read more

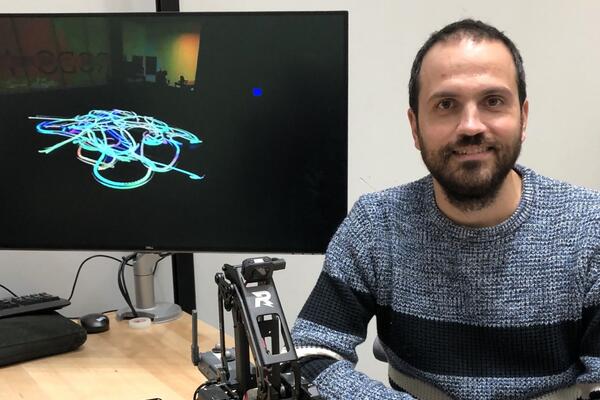

Robots the size of a soccer ball create new visual art by trailing light that represents the “emotional essence” of music

Read more

Waterloo prof leads a team of researchers to improve water quality through a community-focused approach underpinned by technical excellence

Read

Engineering stories

Visit

Waterloo Engineering home

Contact

Waterloo Engineering

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.