New system revs up efficiency of internal combustion engines

A decade of research at Waterloo Engineering has yielded promising new technology to boost the efficiency of internal combustion engines

A decade of research at Waterloo Engineering has yielded promising new technology to boost the efficiency of internal combustion engines

By Brian Caldwell Faculty of EngineeringA decade of research at Waterloo Engineering has yielded promising new technology to boost the efficiency of internal combustion engines.

Validated tests in the lab have shown gains of more than 10 per cent for a patented system to open and close engine valves, an innovation that would save money while also reducing greenhouse gas emissions.

Both simple and reliable, the technology could significantly reduce fuel consumption in everything from ocean-going ships to compact cars.

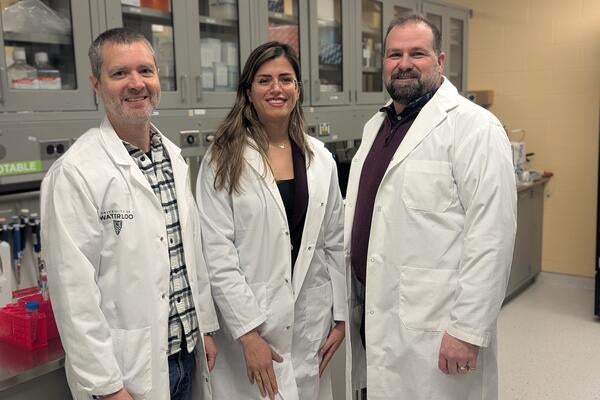

“This method has the potential to bring the well-established benefits of a fully variable valve system out of the lab and into production engines because cost and complexity aren’t issues,” said Amir Khajepour, a professor of mechanical and mechatronics engineering who led the research.

Intake and exhaust valves in internal combustion engines are typically controlled by cam mechanisms that do not allow the timing of their opening and closing to be varied.

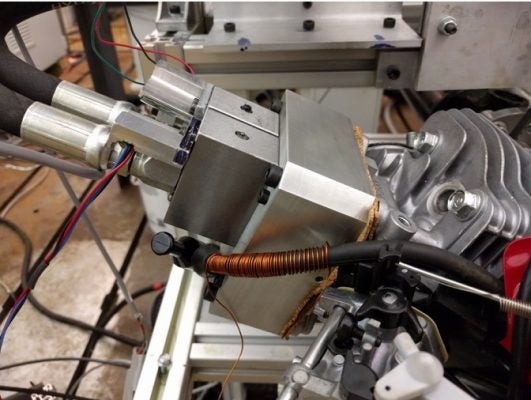

The technology developed by Waterloo researchers replaces cams with hydraulic cylinders and rotary hydraulic valves that enable fully variable timing as the speed and torque of an engine change.

That ability to specifically time the opening and closing of valves based on engine operation is a key to reducing fuel consumption.

“If you think about an ideal solution, it is to make the motion of the valve completely controllable,” said Khajepour, a Canada Research Chair and director of Waterloo’s Mechatronic Vehicle Systems Lab. “That gives you infinite options to work with.”

Although other systems to vary valve timing exist, they are limited to use in experimental engines in laboratories due to their high cost and complexity.

“The cost of our technology is much, much lower than any other fully variable valve system,” said Khajepour.

The Waterloo system’s relative simplicity and resulting reliability pave the way for its use in engines for power generation, mining vehicles, the trucking industry and a host of other applications, including the consumer automotive market.

Khajepour said an affordable, dependable system to vary valve timing in internal combustion engines could substantially reduce society’s carbon footprint during the transition to cleaner electric powertrains over the next few decades.

“We should be able to easily improve efficiency by over 10 per cent, which is significant,” he said.

A study on optimizing the hydraulic variable valve system, which builds on research that began in 2008, recently appeared in the journal Mechatronics.

Also involved in the work were Mohammad Pournazeri, Matthew Chermesnok, Mohammad Sharif, Yangtao Li, Mitchell Terpstra and Yanjun Huang.

Read more

Two University of Waterloo affiliated health-tech companies secure major provincial investment to bring lifesaving innovations to market

Read more

Researchers engineer bacteria capable of consuming tumours from the inside out

Hand holding small pieces of cut colourful plastic bottles, which Waterloo researchers are now able to convert into high-value products using sunlight. (RecycleMan/Getty Images)

Read more

Sunlight-powered process converts plastic waste into a valuable chemical without added emissions

Read

Engineering stories

Visit

Waterloo Engineering home

Contact

Waterloo Engineering

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.