Startup taps into maker market with a DIY soldering iron

Waterloo Engineering students win $10,000 for their capstone design project - a soldering iron that’s safer and easier to use

Waterloo Engineering students win $10,000 for their capstone design project - a soldering iron that’s safer and easier to use

By Carol Truemner Faculty of EngineeringThe maker movement — a global do-it-yourself culture of people who make things — has inspired a group of Waterloo Engineering students to create a soldering iron that’s safe and easy to use.

“We specifically designed the Solder Otter for the Maker Market,” said Vanessa Guido, a systems design engineering student and chief executive officer of Solder Otter. “We’ve had a lot of great feedback on our product.”

The Solder Otter (top) with built in exhaust system compared to a traditional soldering iron.

A soldering iron is a hand tool used in manufacturing electronics. It’s dangerous because it heats up to 400 degrees Celsius and creates fumes. The new design from Solder Otter is easier to use than traditional solder irons and has built-in fume extraction and a HEPA filter so that ordinary people can use it to build electronics.

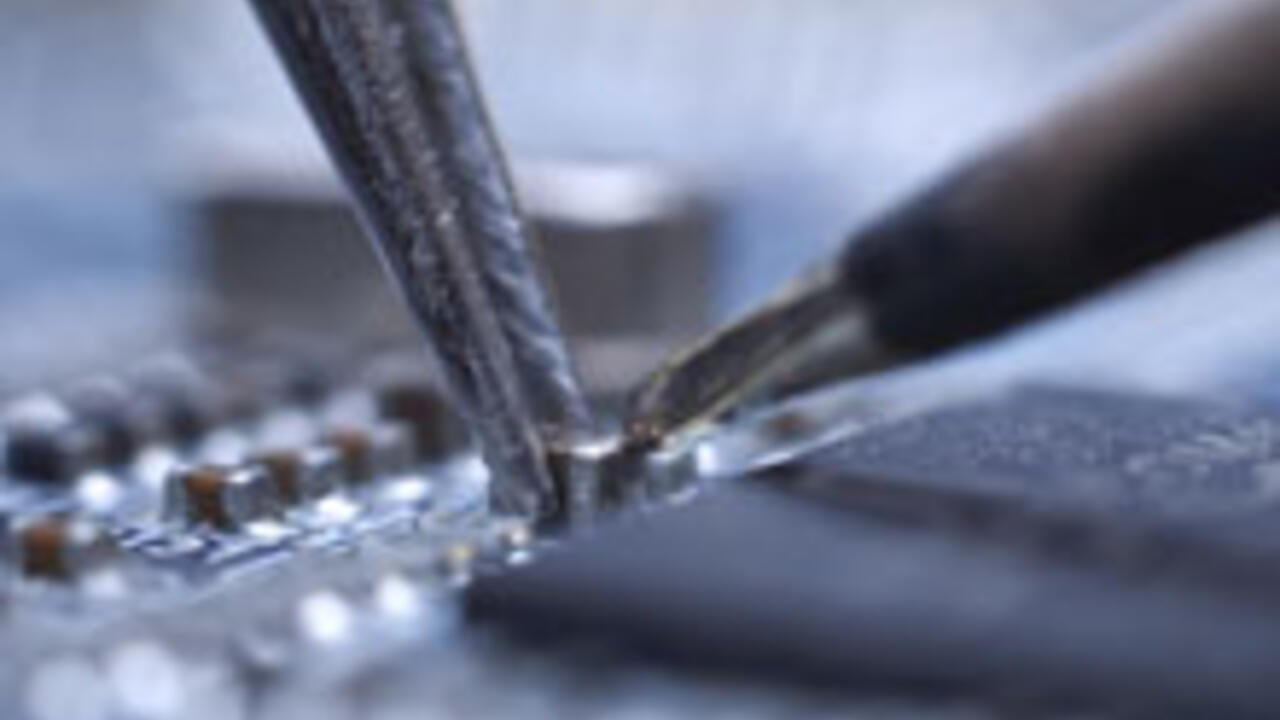

The company’s five founders are undergraduate mechanical engineering and systems design engineering students. They developed the Solder Otter as part of their capstone design project, a unique opportunity for engineering students at the University of Waterloo to conceptualize and design a project related to their chosen discipline.

Top row (from left to right): Daniel Weng, Mark Vaz, Stephen Gill. Bottom row (from left to right): Vanessa Guido, Brian Wildsmith

Previous capstone projects have given rise to groundbreaking ideas leading to the creation of companies such as Athos, BufferBox, Thalmic Labs and Pebble.

Recently, Solder Otter won $10,000 at the second annual Norman Esch Capstone Design Awards competition for Waterloo Engineering students.

Other $10,000 winners included:

Autowalk, a motorized kneebrace that helps straighten the leg, received $3,000 for being the People’s Choice winner.

During the event, 15 teams had 90 seconds to pitch their businesses to a panel of judges who included engineering professors and faculty members of the Conrad Entrepreneurship, Business and Technology Centre. Judges weighed the overall pitch, and product innovation, market potential and viability.

“The presentations were all extremely solid and well done,” said Matt Stevens, chief executive officer of Waterloo-based CrossChasm Technologies Inc. “I was especially impressed by the way each team focused on the end user of its project and how it would be of benefit to the individual.”

Judges selected the finalists for the competition from 60 applicants who all participated in March’s annual Capstone Design symposia. The five-day event showcased over 150 projects senior engineering students spent months designing and building.

Read more

Here are the people and events behind some of this year’s most compelling Waterloo stories

Read more

Meet the five exceptional graduate students taking the convocation stage as Class of 2024 valedictorians

Read more

Meet the 13 exceptional students representing Waterloo’s newest grads

Read

Engineering stories

Visit

Waterloo Engineering home

Contact

Waterloo Engineering

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.