Maglev Microrobotics Laboratory

Maglev Microrobotics Laboratory studies the design and development of magnetically levitated (Maglev) robots. To accomplish this, a magnetic levitation setup enabling high precision 3D remote positioning was built. Our Maglev systems find applications in areas spanning various disciplines such as:

- Contactless micromanipulation and microrobotics

- Manipulation in hazardous environment

- Clean rooms applications

- Wind tunnel testing

- Wafer growth and wafer transportation

We are working on the development and industrialization of various applications of magnetism such as electromagnetic energy harvesters and non-destructive testing for detecting cracks and defects in live pipelines.

Please contact us for more information.

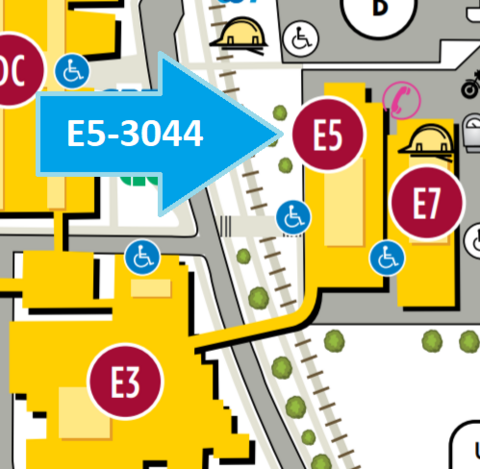

We are also affiliated with Robohub in E7 building. A maglev floor is currently under construction in Robohub!

Learn More about the Maglev Microrobotics Laboratory on their website: https://uwaterloo.ca/maglev-microrobotics-laboratory/

Contact

|

(519) 888-4567 x35095 Email |

Laboratory Goals

Manipulation in hazardous environments

Teleoperation of magnetically levitated robotic systems are widely used in operations in hazardous environments. In this way, secure operation and safe handling of materials can be achieved in nuclear reactors and biohazard laboratories.

Clean rooms applications

Magnetic levitation is also appropriate for stepper stages in photolithography. The magnetically levitated stages can be positioned with nanoprecision and allow roll, pitch and yaw motions. Since energy is provided outside, thermal extension problems are overcome.

Wind tunnel testing

Since magnetic levitation enables contactless manipulation of objects, it is favorable for wind tunnel testing. Magnetic levitation is extensively used by top aircraft and missile companies to test aerodynamics of their designs.

Wafer growth and wafer transportation

High precision magnetic levitation systems are ideal for wafer growth from silicon melt because magnetic levitation is a dust free operation. In recent years, maglev transportation systems are realized utilizing silicon wafer transport with no risk of contamination.