Innovation injection

Life-enhancing engineering research continues to advance despite the COVID-19 pandemic

Life-enhancing engineering research continues to advance despite the COVID-19 pandemic

By Brian Caldwell Faculty of EngineeringAs the COVID-19 case count swelled and subsided in successive waves, triggering restrictions on normal life with corresponding degrees of severity, it was clear there would be no quick fix to our once-in-a-century health crisis.

For professors, alumni and students at Waterloo Engineering, that meant a stiff test of the resilience, determination and innovation that have long been hallmarks of its commitment to making the world a better place.

More than 19 months into the pandemic, it is safe to say many, many of them are passing that test with flying colours.

In some cases, the crisis itself has inspired new lines of research or twists on old ones to give doctors and ordinary citizens better tools to help fight back against the virus.

In others, researchers, students and aspiring entrepreneurs have found innovative ways – often working remotely from home instead of in the lab – of pressing on with promising projects that were launched pre-pandemic.

Here are seven examples, with insights and observations from the innovators themselves, of initiatives inspired by, or advanced despite, the enormous challenges of COVID-19.

While others reeled during the pandemic’s unsettling early days, Alexander Wong (BASc ’05, computer engineering, MASc ’07, electrical and computer engineering, PhD ’10, systems design engineering) rolled up his sleeves and got to work.

While others reeled during the pandemic’s unsettling early days, Alexander Wong (BASc ’05, computer engineering, MASc ’07, electrical and computer engineering, PhD ’10, systems design engineering) rolled up his sleeves and got to work.

A systems design engineering professor and director of the Vision and Image Processing (VIP) Lab at Waterloo, Wong and colleagues launched an ambitious project to detect infections using chest x-rays and artificial intelligence (AI) software.

The open-source COVID-Net initiative, which also involves spin-off startup DarwinAI, has since yielded technology with promising ability to both identify COVID infection and determine its severity, a key to formulating treatment plans.

Q. What motivated you to take on such a big problem?

A. We’re used to tackling complex, real-world problems at Waterloo, so for me it wasn’t daunting. I saw it as a great challenge, both from an academic perspective and in terms of potential impact.

Engineering is all about turning fundamental knowledge, science and technology into something tangible to help the global community. To be able to do that, even in a small way, is very gratifying.

Q. Aren't medical experts afraid you want to displace them?

A. It’s not about replacing clinicians, but giving them tools and information to make faster, more consistent decisions. There is perfect synergy between AI and medicine. A lot of clinicians I talk to welcome AI now because they have a new appreciation that it is going to help them deliver better care to more people.

Q. How do you see the technology progressing?

A. What really hits home from our COVID experience is the growing need for computer-aided clinical decision support in other areas of medicine, including oncology and infectious diseases like tuberculosis, especially with the hybrid health-care system – in-person and remote – that is emerging. We’re convinced this technology has tremendous potential beyond COVID.

With a resume that includes co-op terms at Harvard University, the Massachusetts Institute of Technology, NASA and Apple, plus a runner-up finish in the global James Dyson Award competition for student inventors, Alisha Bhanji (BASc ’20, nanotechnology engineering) could probably have her pick of great jobs at established companies.

With a resume that includes co-op terms at Harvard University, the Massachusetts Institute of Technology, NASA and Apple, plus a runner-up finish in the global James Dyson Award competition for student inventors, Alisha Bhanji (BASc ’20, nanotechnology engineering) could probably have her pick of great jobs at established companies.

But after getting bitten by the entrepreneurship bug during her undergraduate years at Waterloo, she is busy instead as the CEO of a startup that is working to develop and commercialize the concept at the core of her fourth-year design project with four classmates.

Scope Photonics, which was co-founded by CTO and fellow alumnus Fernando J. Peña Cantú, aims to revolutionize compact cameras for everything from smartphones to autonomous vehicles with a tiny, high-quality zoom function using lenses comprised of electronically tuned liquid crystals.

Q. How hard is it to build a technology company from the ground up?

A. It’s incredibly difficult and nobody realizes the magnitude of difficulty going in, which is probably a good thing. If you knew at the beginning, maybe you wouldn’t do it.

You have to do a lot of balancing because you’re working with limited funding and a small team. The benefit of that is you’re more nimble and agile, so you can quickly adapt to challenges and hurdles, but you have to be really careful about how you spend your time and resources.

Q. What keeps you going, especially with COVID making it particularly difficult to work on new hardware?

A. It’s all part of the Waterloo mentality. You learn to be resilient in the face of adversity because of everything you deal with as a student. You’re also surrounded by entrepreneurship – everything from Velocity Science to Capstone Design, where the goal is to create something new with your education, this knowledge you have access to, that can really help other people.

Years of prior research allowed Sushanta Mitra (PhD ’01, mechanical engineering) to hit the ground running when he set his sights on development of a fast, easy, accurate, inexpensive, at-home test to detect the COVID-19 virus in saliva.

Years of prior research allowed Sushanta Mitra (PhD ’01, mechanical engineering) to hit the ground running when he set his sights on development of a fast, easy, accurate, inexpensive, at-home test to detect the COVID-19 virus in saliva.

The basic concept – environmentally friendly paper strips that change colour when nanoparticles of various chemicals react to virus spike proteins – is at the heart of work the mechanical and mechatronics engineering professor previously did to invent a test for E. coli bacteria in drinking water.

Pivoting to the pandemic battle meant building on lessons already learned by teaming up with Waterloo chemistry professor Juewen Liu and industry partner ChitoLytic Inc. Together they’re aiming to bring simple spit tests to market that cost less than $2 and yield results in under 20 minutes.

Q. How important is making your test so inexpensive?

A. Sustainability, affordability and technology for the masses – these three factors are critical to our mission.

Frugal innovation empowers people to take control of their own health. We believe this technology could have the biggest impact in the developing world, where the cost of testing is often an impediment. It will also be valuable in settings such as long-term care facilities, where residents can’t easily go to testing centres, and Indigenous communities where access to health care is questionable. An easier, cheaper test should increase COVID detection, slow transmission of the virus and therefore help reduce the death and suffering it causes.

Q. Do you foresee any secondary benefits?

A. We hope our test will also help with planning and the activation of health-care measures. When you know where hotspots are because you are doing more testing, you can target vaccine booster doses, for example.

Who knows what is still in store for us? Reliable information and insights that help inform health-care strategies will be crucial.

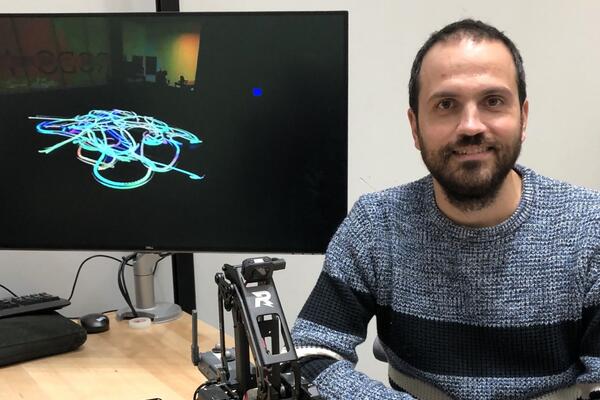

More than five years into research to make robotic exoskeletons autonomous by giving them eyes, Brokoslaw Laschowski (MASc ’16, mechanical engineering, PhD ’21, systems design engineering) may just be getting started on his life’s work.

More than five years into research to make robotic exoskeletons autonomous by giving them eyes, Brokoslaw Laschowski (MASc ’16, mechanical engineering, PhD ’21, systems design engineering) may just be getting started on his life’s work.

The challenge of combining computer vision and deep-learning artificial intelligence (AI) in wearable robots is so complex, he is fully prepared to spend a career creating and refining the technology to help people with mobility issues.

His basic concept, developed in the Motion Research Group lab under the supervision of Professor John McPhee, is to fit exoskeletons with vision via cameras so they can mimic the way able-bodied people walk by seeing their surroundings and adjusting their movements accordingly.

cameras so they can mimic the way able-bodied people walk by seeing their surroundings and adjusting their movements accordingly.

Q. You've publicly released your work so other researchers can use it. Why?

A. I’m proud to have made my PhD research open source.

The hope is that researchers around the world will overtake the performance of my results and it will start an informal, friendly competition. This is an extremely challenging problem and we all need to work together in some collaborative way, even though we’re friendly competitors.

Allowing people with spinal cord injuries and strokes to walk again is a long-term objective that is too big for one person, or one research lab, to achieve alone.

Q. Why are you so committed to this research?

A. I believe I had the right idea at the right time. Had I come up with this concept of adding wearable cameras to robotic exoskeletons even 10 years ago, the technology wouldn’t have existed. Cameras were too large and computing algorithms weren’t accurate enough. Now the technology is here, I probably would have regretted it years from now if I hadn’t pursued this innovative research project and somebody else did – and they got to go on this amazing journey instead of me.

Finishing second in a prestigious international design-build competition this spring was icing on the cake for senior design lead Gabrielle Tuck (BASc ’21, civil engineering) and more than 200 other contributors to Warrior Home.

Finishing second in a prestigious international design-build competition this spring was icing on the cake for senior design lead Gabrielle Tuck (BASc ’21, civil engineering) and more than 200 other contributors to Warrior Home.

By the time the student team impressed judges at the Solar Decathlon, an event sponsored by the U.S. Department of Energy, with the net-zero bungalow it designed and built, an Indigenous family was already living in it about two hours north of campus.

The team’s double-pronged approach – community project combined with theoretical challenge – added a rich layer to the experience as an event featuring universities from as far afield as Chile was delayed, but not derailed, by COVID-19.

Q. What did it mean to build a house for people who you actually met and consulted with?

A. That had a huge impact because we weren’t just increasing our own knowledge and learning new skills for a competition.

There was a real goal and this house was for a real family who needed it. That made everyone all the more passionate and super-attentive to detail. We double-checked everything. It wasn’t just theoretical. It actually needed to work and work well, so that put the pressure on and motivated us all.

Q. What was the most valuable lesson you learned in your 3 ½ years on the project?

A. The greatest takeaway for me was the importance of communication and co-ordination. Especially in civil engineering, there are so many systems that need to be integrated, whether it’s on the technical side or systems of people. The mechanical system has to be checking in with architecture and checking in with structure, and vice-versa, because everything can be influenced by everything else. We learned that in class, of course, but really doing it reinforced those lessons in a powerful way.

It was much more than an academic exercise or a technical challenge when Ala Eldin Omer set out to develop a painless way for people with diabetes to monitor their blood glucose levels about four years ago.

It was much more than an academic exercise or a technical challenge when Ala Eldin Omer set out to develop a painless way for people with diabetes to monitor their blood glucose levels about four years ago.

His own father has type 2 diabetes, so the doctoral candidate in electrical and computer engineering has seen first-hand how painful, costly and inconvenient testing is with existing technology requiring users to prick their fingers and draw blood.

The extra motivation of a personal connection helped Omer and his collaborators invent a prototype, palm-sized device that uses radar and artificial intelligence (AI) to non-invasively read glucose levels through the skin when users place their finger on a touchpad.

intelligence (AI) to non-invasively read glucose levels through the skin when users place their finger on a touchpad.

Q. Was there a motivator, in addition to your father, to take on such a big challenge?

A. After I built an academic foundation with my first two degrees, I really wanted to pursue research that could impact lives, not just remain in published papers. Many PhD candidates these days prefer to focus on one particular part of a problem within their comfort zone. I decided to be different by not being afraid to attack multi-faceted, complex research.

Q. What is at the core of the problem you identified?

A. We found that frequent self-monitoring is crucial to controlling the disease and averting disastrous complications, but issues related to available finger-pricking technology – pain, risk of infection, cost, inconvenience – can lead to non-compliance and insufficient daily measurements. Our ultimate goal is pain-free, continuous monitoring to reflect long-term patterns and trends in glucose fluctuations.

Q. How do you see your technology evolving as research and refinement continue?

A. The target is a wearable device similar to a smartwatch. If we reached that point, it would be awesome and we could then initiate the stages of commercialization needed to bring it to market.

Lessons learned as a graduate student in the Multi-Scale Additive Manufacturing (MSAM) Lab at Waterloo are now guiding Elham Davoodi (PhD ’21, mechanical engineering) in a related line of health research in California.

Lessons learned as a graduate student in the Multi-Scale Additive Manufacturing (MSAM) Lab at Waterloo are now guiding Elham Davoodi (PhD ’21, mechanical engineering) in a related line of health research in California.

Davoodi earned her doctorate by developing a durable, flexible sensor that features ultrathin layers of graphene embedded in silicone rubber. Made possible by 3D printing and nanotechnology, the new material is ideal for wearable devices such as wristbands and shoe insoles to monitor vital signs or athletic performance because the graphene creates electrical signals when it moves or bends.

Since starting work this past summer as a postdoctoral fellow at the California Institute of Technology, she has been focused on the creation of conductive gels that could be applied to internal organs for monitoring or to improve the function of damaged tissue.

Q. What is the basic idea behind your new area of research?

A. Instead of sensors for external applications, we are trying to make hydrogel sensors that mimic human tissue and are compatible, sensitive and conductive enough for internal applications.

conductive enough for internal applications.

One example could be applying a gel to the heart to directly sense and monitor its signals. This kind of tissue engineering requires a soft gel that is conductive and still conforms well to very soft organs.

Q. What is the common thread running through your recent research work?

A. I’m concerned with the development of conductive materials for health monitoring using both external and internal devices. When I reviewed the literature, it struck me that most health monitoring devices right now are rigid and I wondered how I could make sensors that are most compatible with the human body, which is soft, not rigid. Taking this approach has produced promising results and I am very pleased with the progress we have made so far.

This article originally appeared in October 2021's WEAL. The full issue is available in a pdf format.

Read more

Robots the size of a soccer ball create new visual art by trailing light that represents the “emotional essence” of music

Read more

Waterloo prof leads a team of researchers to improve water quality through a community-focused approach underpinned by technical excellence

Read more

New medical device removes the guesswork from concussion screening in contact sports using only saliva

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.