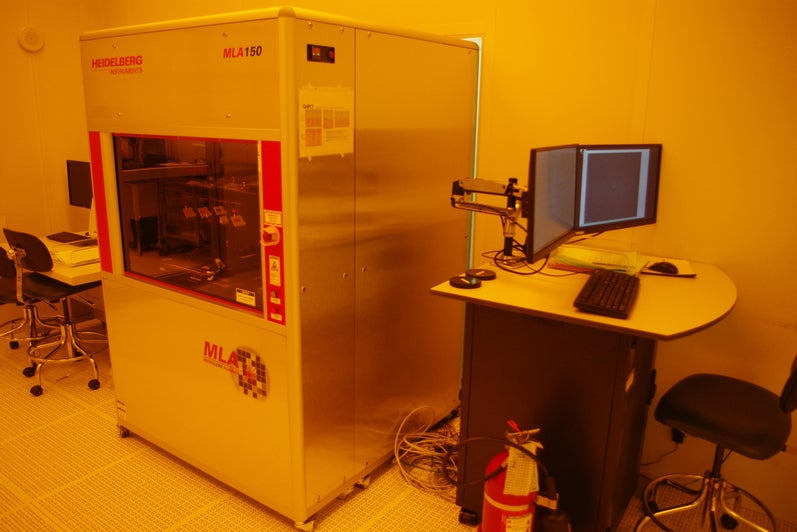

Vendor: Heidelberg Instruments

Model: MLA150 direct write UV lithography system

Purpose: Alignment and UV exposure of resist-coated wafers

Equipment description:

The MLA150 is a high speed direct write lithography tool capable of exposing photo-sensitive resists. The ability to expose patterns directly without fabrication of a mask, allows for increased design flexibility, and shorter prototyping cycles. The tool is equipped with a pair of diode lasers operating at 405 nm and 375 nm, allowing exposure of a wide range of resist types. Topside and backside cameras allow for alignment to previously patterned features with high accuracy. The stage can accommodate pieces from 8 mm x 8 mm squares up to 9″ wafers. The MLA software offers a number of exposure modes, pattern manipulation, and distortion compensation.

System features and options:

- Dual light source: 405 nm laser (broadband resists), 375 nm laser (i-line resists)

- Backside alignment

- Alignment accuracy: 0.5 μm (front side alignment), 1.0 μm (back side alignment)

- Minimum substrate size = 8 mm x 8 mm square

- Maximum pattern area = 150 mm x 150 mm

- Two different write speeds: high quality (down to 1 μm resolution) and high speed (~2.5 times faster)