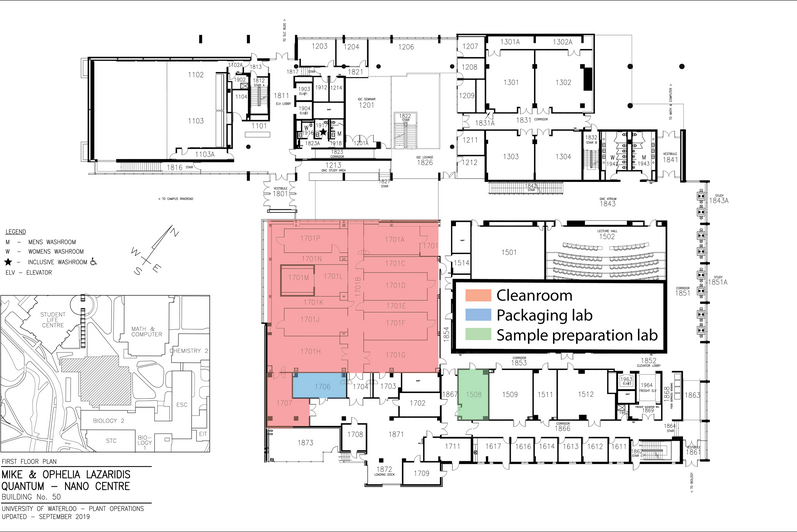

The QNC cleanroom is situated on the main floor of the Mike and Ophelia Lazaridis Quantum-Nano Centre. It is an approximately 8000 sq. ft. clean working space with lab rooms built to ISO class 6, 5 and 4 levels of particle attenuation. The QNC cleanroom boasts over 50 tools for the fabrication and characterization of quantum and nano devices, including unique capabilities in electron beam lithography, reactive ion etching and the deposition of superconducting thin films. The cleanroom boasts temperature control to within 1°C and humidity control to within 3% RH. The electron beam lithography bay boasts improved temperature control to within 0.1°C and construction to control room vibrations to the VC-E level.

Equipment list

Deposition

- Atomic layer/plasma enhanced chemical vapor deposition cluster [OXFORD-cluster]

- Evaporator: Al superconducting films [PLASSYS-Ebeam]

- Evaporator: E-beam and thermal [INTLVAC-Ebeam]

- Evaporator: thermal [ANGSTROM-Thermal]

- Oxidation [TYSTAR1-atm]

- Low pressure chemical vapor deposition: silicon nitride [TYSTAR2-nitride]

- Low pressure chemical vapor deposition: poly-silicon [TYSTAR3-PolySiC]

- Low pressure chemical vapor deposition: low temperature oxide [TYSTAR4-LTO]

- Rapid thermal processor #1 [ALLWIN-RTP]

- Rapid thermal processor #2 [ALLWIN-RTP2]

- Sputter: Nb superconducting films [PLASSYS-sputter]

- Sputter: Twin chamber [AJA-sputter]

Lithography

- Beamer/Tracer software package [BEAMER]

- E-beam lithography 30kV [RAITH-EBL]

- E-beam lithography 100kV [JEOL-EBL]

- Mask aligner: front/back capable [SUSS-align]

- Wafer bonder [SUSS-bond]

- Oven: convection [FISHER-oven]

- Oven: HMDS and image reversal [YES-HMDS]

- Spin coat: dual general purpose [REYNOLDSTECH-twincoater]

- Spin coat: E-beam resist station [BREWER-Ebeamspinbake]

- Spin coat: UV resist station [BREWER-UVspinbake]

- UV direct write [HEIDELBERG-MLA]

Dry etch

Wetbenches

- Bulk silicon etch [REYNOLDSTECH-bulkSi]

- Critical point dryer [TOUSIMIS-CPD]

- Diffusion pre-clean [RCACLEAN]

- E-Beam resist develop [DEVELOPEBL]

- Hydrofluoric acids only [HFACID]

- Non-HF acids and bases [ACIDBASEnonHF]

- Solvent processing #1 [SOLVENT1]

- Solvent processing #2 [SOLVENT2]

- UV resist develop [DEVELOPUV]