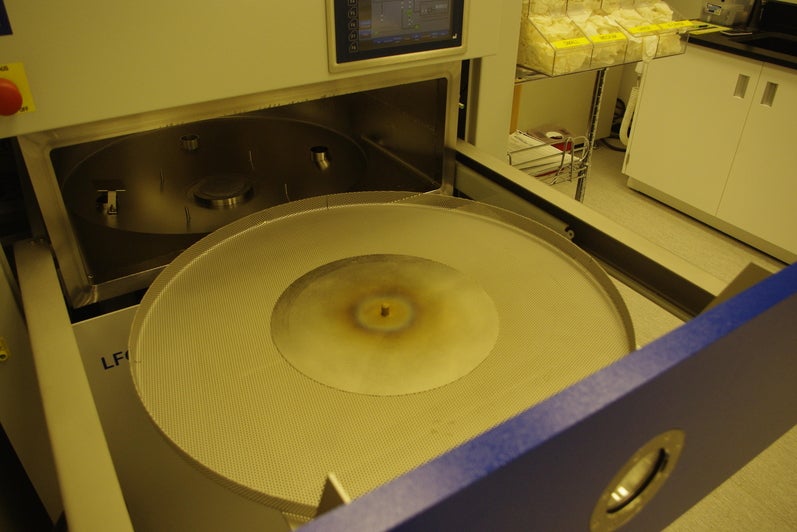

Vendor: SAMCO UCP

Model: LFC150G

Purpose: Surface cleaning and passivation of semiconductor packages

Equipment description:

The LFC150 G is configured for batch plasma processing of strips placed in slotted magazines and of wafers. The UCP plasma cleaning concept is based on chemical reactions of gas-phase species with the contaminated surface. This is accomplished by exposing the substrates to a DC plasma. The system is equipped with a high vacuum pumping station consisting of a purged turbomolecular pump, a rotary vane pump, a high vacuum valve, and a hydrogen generator. The LFC150 G has an excellent throughput and is suited for a wide variety of applications. Multi-step processing allows to combine the advantages of both, hydrogen and nitrogen plasma.

System features and options:

- Remote direct current (DC) plasma for effective cleaning with extremely low bias for reduced damage to sensitive samples.

- On board H2 generator for standard Ar/H2 plasma process

- Available N2 gas

- Redundant filamants for reliable operation

- In-chamber temperature sensor to avoid thermal damage to samples

Typical applications:

- Cleaning samples prior to wire bonding for improved bond strength

- Cleaning dies prior to die bonding

- Cleaning prior to die encapsulation