Vendor: TYSTAR

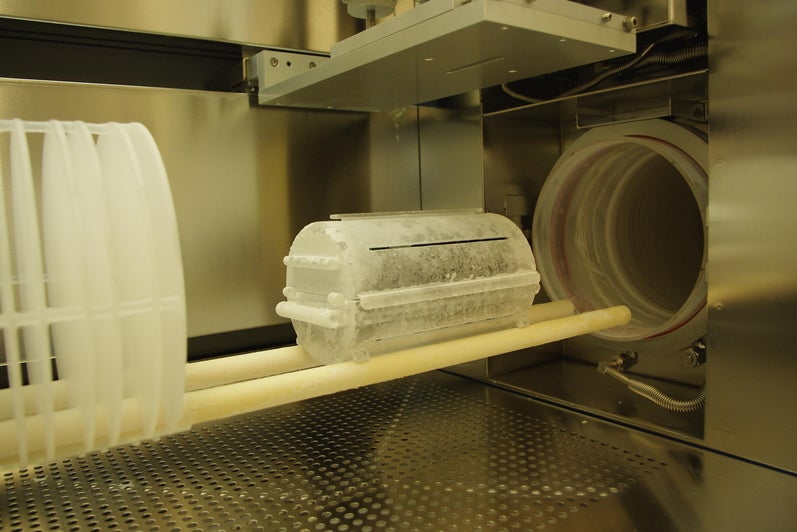

Model: Tytan 4600 mini fourstack horizontal furnace

Purpose: Low temperature oxide and doped oxide deposition via low pressure chemical vapor deposition (LPCVD)

Equipment description:

Tube #4 of the Tystar furnace stack is dedicated to growing low temperature SiO2 (LTO) and doped SiO2 (DLTO) films via low pressure chemical vapor deposition (LPCVD). This tube is capable of processing up to 26 wafers with processing temperature of 400-450°C. Uniformity for a 500 nm LTO film should be 5% within wafer, 5% wafer to wafer, and 5% run to run. Uniformity for a 500 nm DLTO film should be 5% within wafer, 10% wafer to wafer (across load), and 5% run to run.

Commissioned processes:

- Low temperature SiO2 (LTO)

- Doped low temperature SiO2 (DLTO)

Gases currently available on this system:

- N2

- 15% PH3 / 85% SiH4

- O2

- SiH4

Additional information:

- This system is configured to handle 100 mm wafers with typical thickness of 550 μm (approx). Processes are not commissioned for other wafer sizes.

- Photoresist-coated wafers are strictly prohibited since the system supports high temperature processes which are not compatible with photoresist films