Vendor: TYSTAR

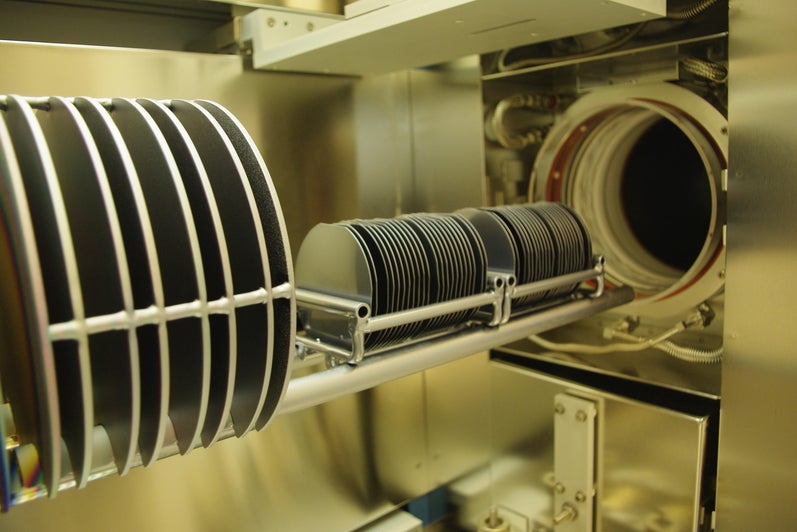

Model: Tytan 4600 mini fourstack horizontal furnace

Purpose: Deposition of doped and undoped films of polysilicon via low pressure chemical vapor deposition (LPCVD)

Equipment description:

Tube #3 of the Tystar furnace stack is designed to be swapped between two tubes for different LPCVD material depositions. The first material is an experimental SiC process which is deposited in the temperature range of 700-800°C. The second material is polycrystalline silicon which may be deposited in the temperature range of 580-650°C in doped (D-Poly) or undoped forms (Poly). Maximum number of wafers for these processes is 50 (Poly) and 26 (D-Poly). Uniformity for a 300 nm polysilicon film should be 3% within wafer, 3% wafer to wafer, and 3% run to run. Uniformity for a 300 nm doped Polysilicon film should be 10% within wafer, 10% wafer to wafer, and 10% run to run with resistivity of 10 Ω/□.

Commissioned processes:

- Polycrystalline Si (Poly)

- Doped polycrystalline Si (D-Poly)

Gases currently available on this system:

- N2

- SiH4

- 15% PH3 / 85% SiH4

- NH3

- SiH2Cl2

- CH3SiH3

- H2

- C2H2

Additional information:

- This system is configured to handle 100 mm diameter wafers with typical thickness of 550 μm (approx). Processes are not commissioned for other wafer sizes.

- Photoresist-coated wafers are strictly prohibited since the system supports high temperature processes which are not compatible with photoresist films.