Vendor: TYSTAR

Model: Tytan 4600 mini fourstack horizontal furnace

Purpose: Wet or dry thermal oxidation and thermal anneal

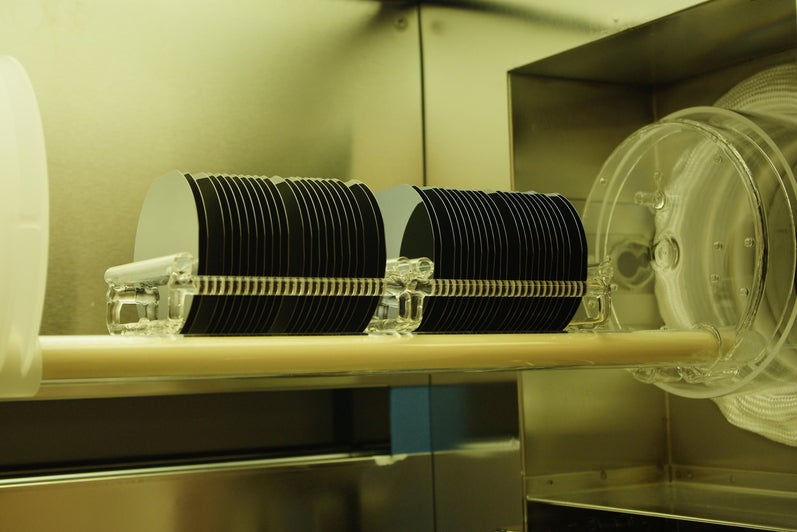

Equipment description:

Tube #1 of the Tystar furnace stack is dedicated to wet (pyrogenic) and dry oxidation of silicon as well as thermal annealing under nitrogen and 10%H2/90%N2 ambient conditions. This tube is capable of processing up to 50 wafers with an upper temperature limit of 1100°C. Uniformity for a 500 nm wet oxidation should be 3% within wafer, 3% wafer to wafer, and 3% run to run. Uniformity for a 200 nm dry oxidation should be 3% within wafer, 3% wafer to wafer, and 3% run to run.

Commissioned processes:

- SiO2 growth via dry oxidation of Si

- SiO2 growth via wet (pyrogenic) oxidation of Si

Gases currently available on this system:

- N2

- 10% H2 / 90% N2

- O2

- Ar

- H2

Additional information:

- This system is configured to handle 100 mm wafers with typical thickness of 550 μm (approx). Processes are not commissioned for other wafer sizes.

- Photoresist-coated wafers are strictly prohibited since the system supports high temperature processes which are not compatible with photoresist films.