Vendor: Twente Solid State Technology B.V.

Model:

PLD

with

in

situ

reflection

high

energy

electron

diffraction

Purpose:

Precise

thin

film

growth

via

pulsed

laser

deposition

Equipment description:

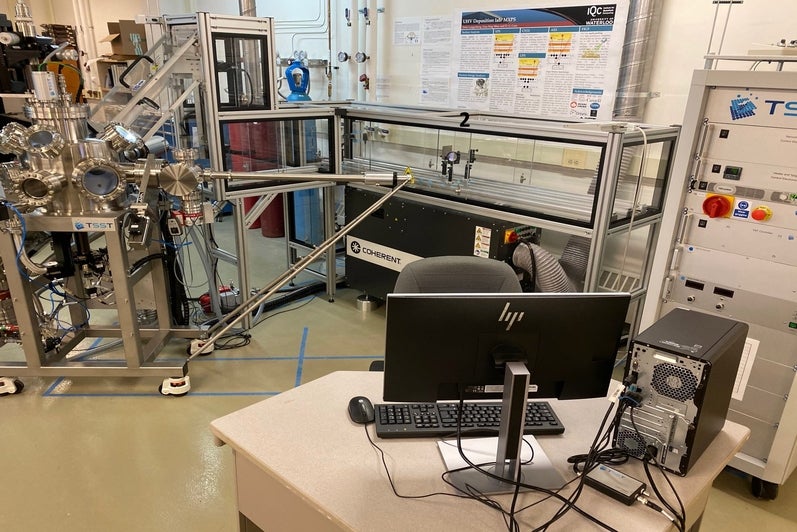

The TSST pulsed laser deposition (PLD) system is a UHV deposition tool that used pulsed laser ablation of a target to grow thin films on your substrate. PLD is a highly energetic film deposition method, well suited to the deposition of complex oxide films where it is important to control the stoichiometry of the grown film. Uniformity over large areas is difficult to achieve with PLD so samples are limited to 2″ (50.8 mm) wafers or smaller samples. This system features ultra-high vacuum (UHV) contruction and compatibility with a reflection high energy electron diffraction (RHEED) for real time crystallogarphic monitoring of the growing film.

Gases currently available

- N2

- O2 (for reactive growth)

- Pre-mix laser gas (0.12% F2, 3.03% Kr, 96.85% Ne)

System features and options

- Loadlock for quick loading of samples and target carousel

- UHV construction and 700 L/s turbopump

- High pressure RHEED for growth monitoring

- Heater stage (900℃ capable) with X-Y and tilt movement

- Laser beam scanning for improved uniformity

- O2 gas introduction to growth chamber through mass flow controller (MFC)

- Pressure control for reactive growth through via both "upstream" and "downstream" methods

Note: This system is capable of operating at temperatures up to 900℃. Uncleaned samples and samples with polymeric films are strictly prohibited. All materials going into this system should specifically be listed in the authorized materials page.