The problem

- Whether tying rebar together or fastening conduit to rebar with pliers, tying the wire requires workers to make repeated, fast hand and arm twisting movements while applying high grasp force.

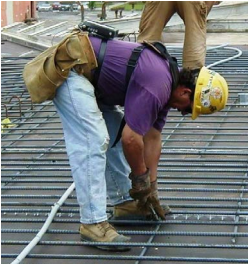

- Tying rebar by hand increases the chance of developing hand-wrist disorders.

- Working at ground level, also increases the risk of low back injuries from frequent and prolonged stooping and bending.

One solution

- Use a mechanical rebar-tying tool.

- This lowers the risk of hand and wrist injury.

- Some rebar tiers allow the worker to work standing up, so there is less stress on the low back.

Tying rebar by hand

Tying conduit to rebar using a mechanical tying tool

How it works

- Both manual and battery-powered rebar tying tools are available to tie rebar steel and electrical conduit to rebar.

- When the head of the tool is placed over the rebar or conduit joint, the trigger is depressed, and the area tied off. Newer generations of these devices have adjustable tension control.

- Battery-powered rebar tiers automatically fasten the bars together with tie wire. They can be used whenever a simple “wrap and twist” tie is needed.

- Battery-powered rebar tiers may not provide the strength of “saddle” ties.

- Several companies offer power rebar tiers. With one tool design, the worker presses the trigger and the tool feeds wire around the bars and then twists and cuts the wire. These models are not stand-up tools, but an adjustable extension handle is available.

- A stand-up power tier uses coiled spring wire to hold the bars together. The tool automatically “screws” (or spins) flat coiled wire around the intersecting bars. This tool was designed using ergonomic principles.

Benefits

- Workers should experience fewer injuries.

- Studies conducted by the National Insitute for Occupational Safety and Health (NIOSH) and the Construction Safety Association of Ontario compared manual methods and one model of power tying tool, and showed that using the power tool may reduce the risk of injury to workers’ hands, wrists, and low back.

- In certain applications, there have been documented increases in productivity. The NIOSH-Ontario studies found that power tying tools can tie rebar twice as fast as hand tying. Actual productivity increases will depend on the type of work and the frequency of tying.

- Contractors and rodworkers who used the power tying tool reported that they preferred and would recommend it for tying rebar for flat work.

- Before using one of these tying tools, make sure the ties are approved for the job you will be doing.

Rebar-tying tool with extension

Rebar-tying tool with coiled spring wire handle

For more information

- Products may also be found on the internet using the following search terms: “rebar tying system.”

- Local contractor tool and equipment suppliers or rental companies may be another source of information.

- For general information on this solution, call the Infrastructure Health & Safety Association of Ontario at 416-674-2726 or 1-800-781-2726.