The main objective of this project is to detect surface and subsurface defects that are embedded inside parts made by additive manufacturing technology.

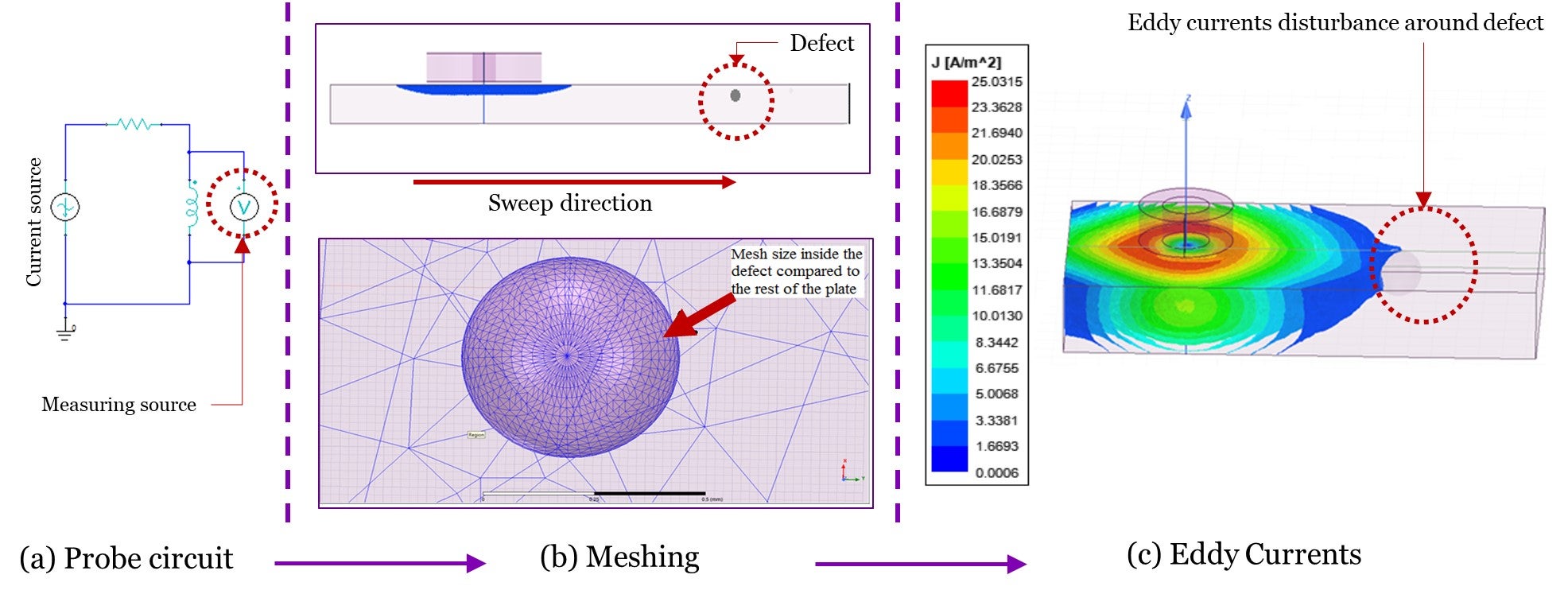

This has to be achieved by optimizing and designing a probe that is sensitive to detect very small defect sizes. Above Figure shows a graphical abstract of the eddy-current non-destructive testing process. The designed probe was successfully able to detect defects in the range of 0.07mm to 0.4 mm in parts made of stainless steel and titanium.

A PhD student, Heba Elsayed Farag, is currently working on this project in collaboration with the Multi-Scale Additive Manufacturing (MSAM) Lab at the University of Waterloo.

List of Publications

- H. E. Farag, E. Toyserkani, and M. B. Khamesee, "Non-destructive testing using eddy current sensors for defect detection in additively manufactured Titanium and Stainless-Steel parts," in Sensors, vol. 22, no. 14, Jul. 2022.